Waste tyre recycling plant

Waste tyre

As people are more and more concerning about the health and environmental, the disposal of various types of wastes, such as waste plastic, waste tyre, waste rubber, medical waste, municipal solid waste and other wastes, becomes more and more urgent problem all over the world and is the current topic.

Many people want to recycle tyres. The investment of waste tyre recycling plant for the waste car and truck tire becomes one of the most profitable and promising industry.

Many people want to recycle tyres. The investment of waste tyre recycling plant for the waste car and truck tire becomes one of the most profitable and promising industry.

Waste tyre recycling plant

The waste tyre recycling plnat is a green technology to solve tyre and other environment pollution which are becoming the serious issues nowadays and it is the meaningful industry. The tyre pyrolysis oil, one kind of end products extracted from the pyrolysis process, is often used for producing heat, electricity, steam and so on.

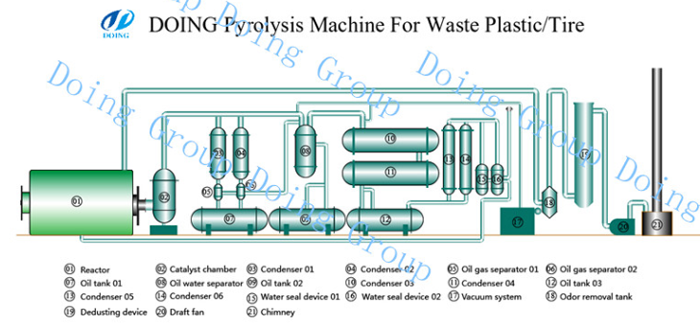

Waste tyre recycling plant working process

Waste tyre recycling plant reactor

Waste tyre recycling plant working process

First of all, put the waste plastics into the pyrolysis reactor.

Secondly, heat the reactor by burning the fuel materials such as coal, or wood, or natural gas, oil. The reactor will be slowly heated, when the temperature reaches around 250 degrees, the oil gas will be generated.

Thirdly, oil gas will be processed by our technology and then goes to cooling system to be liquid oil. The gas which can not be liquefied under normal pressure will go back to combustion system. It will replace the fuel material to burn the reactor, which is energy saving and environment friendly.

Fourthly, after finishing oil production, the temperature of reactor will be down. When the temperature falls down to 40 degrees, the carbon black can be discharged automatically.

Lastly, the hot smoke produced from the reactor can achieve national emission standard after being processed by the advanced dedusting system.

Waste tyre recycling plant Configuration:

Secondly, heat the reactor by burning the fuel materials such as coal, or wood, or natural gas, oil. The reactor will be slowly heated, when the temperature reaches around 250 degrees, the oil gas will be generated.

Thirdly, oil gas will be processed by our technology and then goes to cooling system to be liquid oil. The gas which can not be liquefied under normal pressure will go back to combustion system. It will replace the fuel material to burn the reactor, which is energy saving and environment friendly.

Fourthly, after finishing oil production, the temperature of reactor will be down. When the temperature falls down to 40 degrees, the carbon black can be discharged automatically.

Lastly, the hot smoke produced from the reactor can achieve national emission standard after being processed by the advanced dedusting system.

Waste tyre recycling plant Configuration:

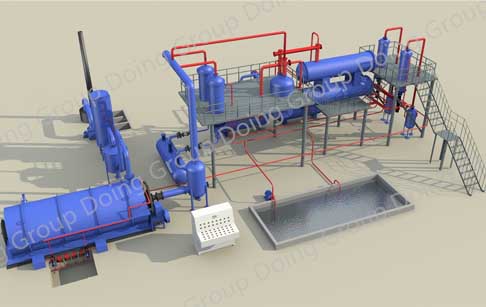

3D picture of waste tyre recycling plant

1. Reactor: Q245R boiler plate, 16mm thickness.

2. Heating way: wood, coal, crude oil, gas

3. Cooling System: Recycled water cooling way.

4. Negative pressure device: guarantee the machine safety, no gas running outside

5. Safety device: automatic alarm, automatic valves

6. Slagging device: Auto slagging system.

7. Final product: crude oil(45%-52%), carbon black(30%-35%), steel wire(10%-15%).

Customer Service:

Our service including:12months warranty; Erecting the plant; Commissioning the plant; Training the operator; Providing of spare parts; whole life’s technical consultant of the plant.

Waste tyre recycling plant technical data2. Heating way: wood, coal, crude oil, gas

3. Cooling System: Recycled water cooling way.

4. Negative pressure device: guarantee the machine safety, no gas running outside

5. Safety device: automatic alarm, automatic valves

6. Slagging device: Auto slagging system.

7. Final product: crude oil(45%-52%), carbon black(30%-35%), steel wire(10%-15%).

Customer Service:

Our service including:12months warranty; Erecting the plant; Commissioning the plant; Training the operator; Providing of spare parts; whole life’s technical consultant of the plant.

| Technical parameter of waste tyre recycling plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste tyre recycling plant | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

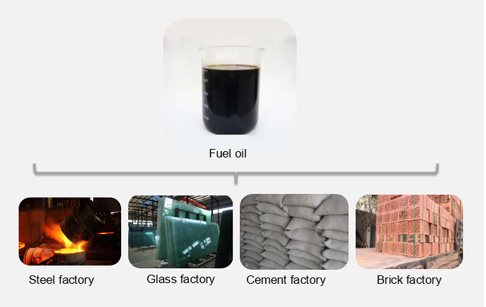

Waste tyre recycling plant final product application

Fuel oil (40% to 45%)

Fuel oil application

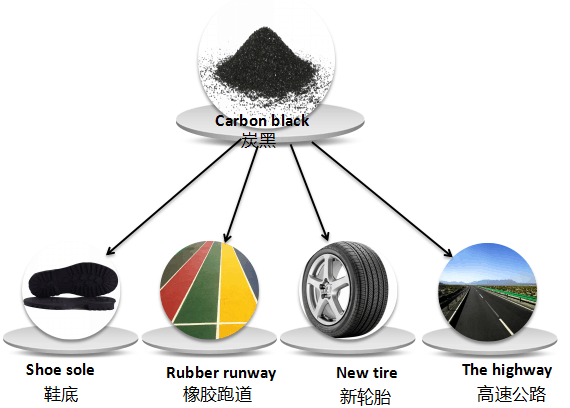

Carbon black (30% to 35%)

Carbon balck application

Carbon black produced by Pyrolysis process (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed;

* Electric cable jacketing

* Conveyor band

* Carrier Bands

* Hose and doormat

* Black nylon bag

* Rubber additive

* Automotive spare parts

* Heat isolation

* Black colorant in rubber materials

* Plastic pipes

* Industrial rubber products

* Fire fighting

Steel wire (10% to 15%)

Tyres contain steel wires and the amount range of 10% to 15% of the total tyre wastage. All of the steel present in the tyre can be detached after pyrolysis recycling process in completed. Valuable steel wires are pressed and sold to steel and scrap dealers.

Gas (10% to 12%)

Non-Condensable gases arise during the pyrolysis process.

Some advantages such as…..

* It has higher calorific value as compared to Natural Gas.

* It can be replaced where Natural Gas and Propane are stored.

* The high energy gas may be utilized as a source of energy for the Pyrolysis process.

* The amount of gas generated in the system is 12% to 15% of the total amount of recycled tyres and considering the 10 ton scrap tyre/day recycling capacity, the facility generates 1200-1500 m3/day gas, which has an enormous energy potential when evaluated.

Request Information

Send your inquiry for further information