Fully continuous tyre pyrolysis plant

Fully continuous tyre pyrolysis plant

Pyrolysis plant installed in different countries

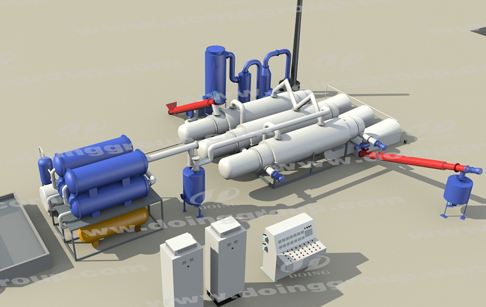

3D draw of Fully continuous tyre pyrolysis plant

The fully continuous tyre pyrolysis plant is equipped with automatic feeding and discharging system, which can realize feeding materials on one side and discharging the slag continuously from the other side. It not only can dispose 30-50 tons waste tyres per day but also can work continuously for 24 hours without a stop.

The raw material of fully continuous tyre pyrolysis plant

Fully continuous tyre pyrolysis plant raw material

Fully continuous tyre pyrolysis plant raw material

1.Waste tire/tyre

2.Waste plastic

3.Waste rubber

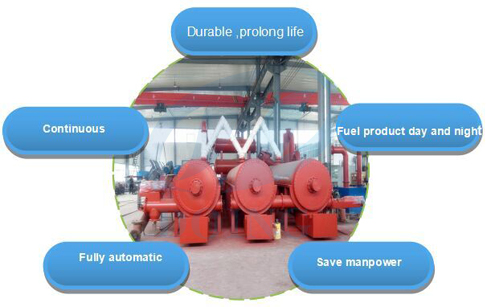

Fully continuous tyre pyrolysis plant advantage

Fully continuous tyre pyrolysis plant advantage

2. The Fully continuous tyre pyrolysis plant produces some gas, which is enough to meet the needs of device self-heating, so the additional fuel consumption is less, and this plant can use own end products of oil as a recycled energy heating for the whole process.

3. Due to its high automation degree, it has a strict demand of the raw material. The tire and rubber should be broken into 30-50mm rubber pieces by the crusher to meet the requirement of the spiral feeding device. As plastic, PET can’t be the raw material for pyrolysis. And the sludge oil should be pre-heated to remove the water. But the working efficiency is increased a lot.

4. The Fully continuous tyre pyrolysis plant can save the labor cost and energy cost, which makes it more profitable than the batch and semi-continuous plant.

Fully continuous waste tyre pyrolysis plant technical data

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

Fully continuous tyre pyrolysis plant final product application

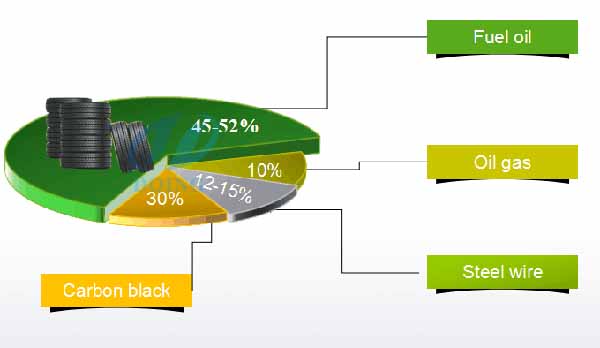

The percent of fully continuous waste tyre pyrolysis plant

Fuel Oil (45% to 52%)

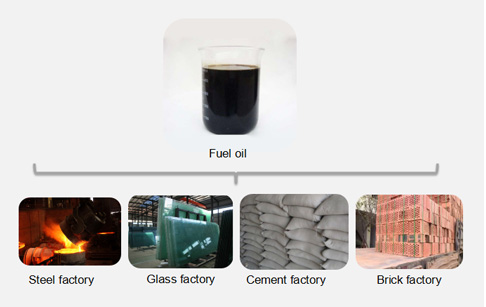

Fuel oil application

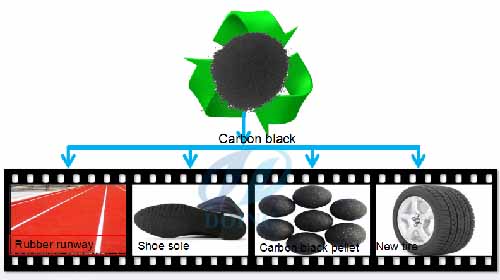

Carbon Black (30%)

Carbon black application

Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Request Information

Send your inquiry for further information