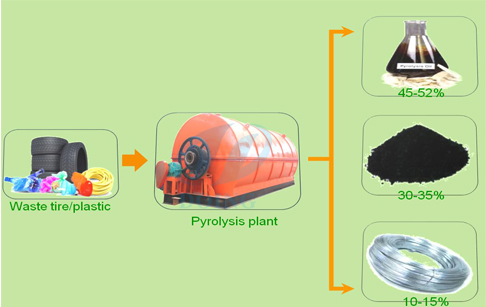

What is pyrolysis of plastic?

Waste Tire/Plastic Pyrolysis Plant / Date:October 10, 2017

Pyrolysis of plastic to oil

Pyrolysis of plastic to oil

1.Feed raw materials

The raw material can be waste tire/waste plastic/waste rubber. Always feed by the auto feeder.

2.Pyrolysis

Include a reactor and catalyst room. Heat the reactor by coal/wood/oil/natural gas. This part will produce high temperature oil gas, the oil gas then flow into the next system.

3. Condensing

Oil gas come out from the reactor and catalyst chamber then cooling down in this part. Condensing system include condenser pipe, oil water separator, horizontal condenser and waste gas condenser. This will make the oil yield to the maximum.

4.Waste gas recovery

This part mainly deal with the gas that cannot be condensed. The whole process is very steady and high efficiency.

5. Discharge

After finished oil produce, the temperature of reactor can be cooled down, When the temperature falls down to 40 degree then carbon black can be discharged automatically by the way of anticlockwise rotate the reactor. The carbon black will drop into slag pool and then use screw conveyor to clean the slag pool. After discharging the carbon black.

Request Information

Send your inquiry for further information