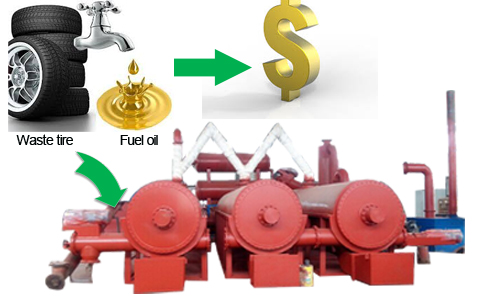

Continuous model waste tire pyrolysis plant

Waste tire

With the improvement of living standards, consumption of cars is also growing. It will lead to the oil resources become less and less, but the scrap tyres become more and more. Due to the rubber waste is difficult to decompose within a short time, tire waste has become a big problem in our surroundings.Continuous overseas service center after-sales service for waste plastic oil pyrolysi plant converting waste tires into oil. Doing pyrolysis plants includes fully automatic waste tire pyrolysis plant ,batch waste tyre pyrolysis plant and refinery pyrolysis plant. Here we will introduce the continuous waste tire pyrolysis plant. It is also called as the continuous model tire pyrolysis plant.

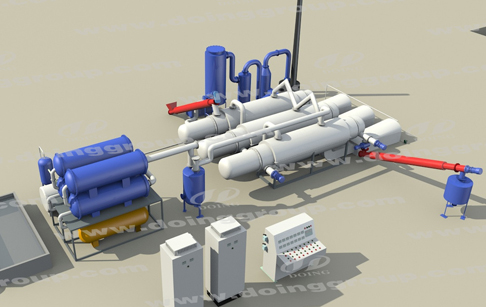

Continuous model waste tire pyrolysis plant

Continuous model waste tire pyrolysis plant 3D picture

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

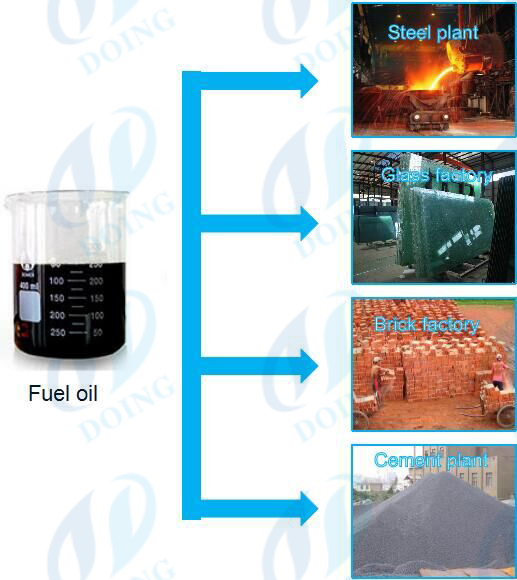

Continuous model waste tire pyrolysis plant final product application

Continuous model waste tire pyrolysis plant final product application

The main application of oil products produced by Doing continuous modelwaste tire pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. 45% to 52% oil of the amount of recycled scrap tires can be carried with licensed tanker trucks.

Steel Wire (12% to 15%)

The third product of continuous modelwaste tire pyrolysis plant is steel wire, the quantity of steel wire is about 12% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

Carbon Black Powder (30%)

Carbon black application

Gases (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Request Information

Send your inquiry for further information