Fully automatic continuous waste tire pyrolysis plant

Fully automatic continuous waste tire pyrolysis plant

This fully automatic continuous waste tire pyrolysis plant has fully automatic process, which can be controlled by PLC system or computer, thus to save the labour cost. And with the automatic and continuous feeding and discharge system, it can make the the pyrolysis system keep running 24/7 without stop, thus to save the valuable time and energy which are consumed in the batch manual operation system.

Fully automatic continuous waste tire pyrolysis plant 3D picture

This fully automatic continuous waste tire pyrolysis plant is also can be used to dispose waste plastic /rubber.

Raw material

Fully automatic continuous waste tire pyrolysis plant advantage

Fully automatic continuous waste tire pyrolysis plant

Our fully automatic conitnuous waste tire pyrolysis plant is controled by PLC system with automatic feeding and discharge system, which only need 1-2 worker for operating the PLC or computer is ok.

2.Fully pyrolysis for high oil output

Our fully automatic conitnuous waste tire pyrolysis plant adopts mutiple reactor design which can make fully pyrolysis of waste tires, thus to get high oil output.

3.Big capacity

Also due to continuous feeding and discharge system, and unique mutiple reactor design, our fully automatic continuous waste tire pyrolysis plant can process at least 10 tons waste tires per day, up to 100T/D.

4.Internal rotating for conitnuous operation

For external rotating system, you have to change the sealing material every three days, thus cannot achieve the real sense of continuous process. But our fully automatic continuous waste tire pyrolysis reactor adopts internal rotating method, which no need to worry about the sealing of the external rotating system.

5.Continuous working save time and energy

6.Long working life

During the continuous pyrolysis process, reactor heating is by indirect hot air heating, which will not damage reactor so much, thus to keep long usage life of the reactors. And since the hard steel wire already removed from waste tires before pyrolysis processs, thus no damage for the reactor.

Fully automatic continuous waste tire pyrolysis plant technical data

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

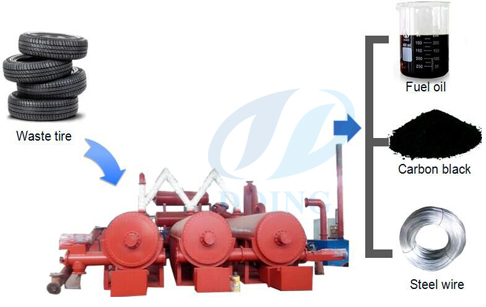

Fully automatic continuous waste tire pyrolysis plant application

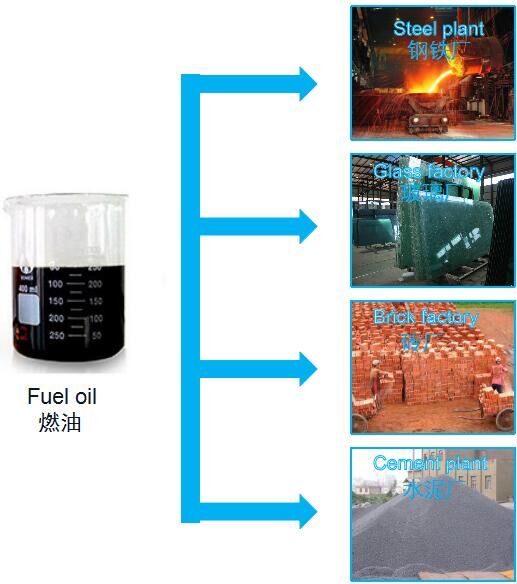

Fuel oil application

The main application of oil products produced by fully automatic continuous modelwaste tire pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. 45% to 52% oil of the amount of recycled scrap tires can be carried with licensed tanker trucks.

Steel Wire (12% to 15%)

The third product of fully automatic continuous modelwaste tire pyrolysis plant is steel wire, the quantity of steel wire is about 12% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

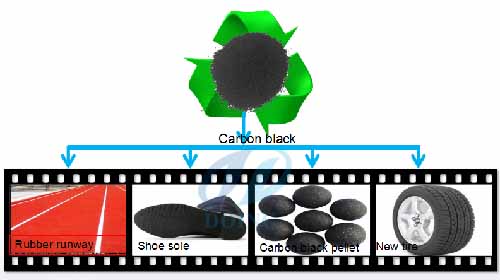

Carbon Black Powder (30%)

Carbon black application

Gases (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Request Information

Send your inquiry for further information