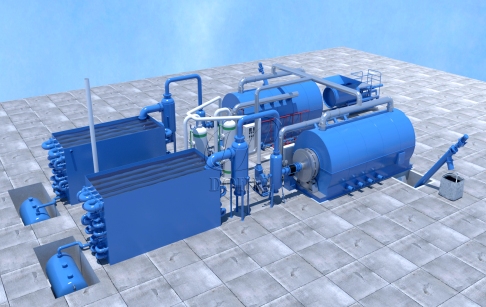

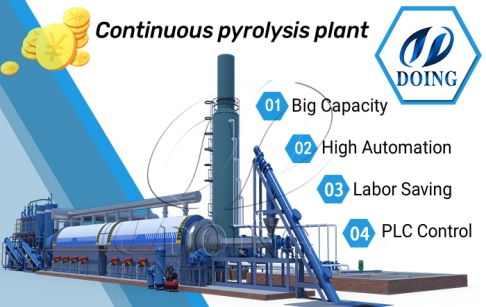

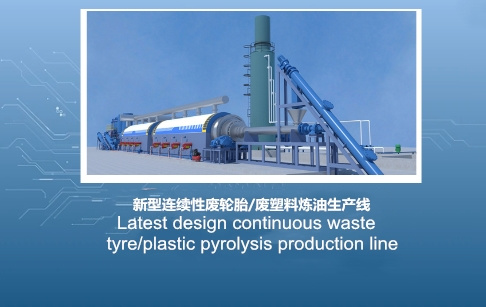

- Continuous Pyrolysis Plant

- Waste Tire Pyrolysis Plant

- Waste Plastic Pyrolysis Plant

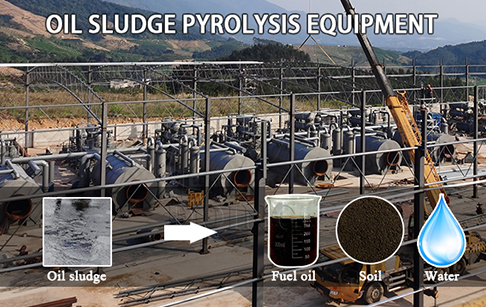

- Oil Sludge Pyrolysis Plant

- Biochar Pyrolysis Plant

- Aluminum Plastic Pyrolysis Plant

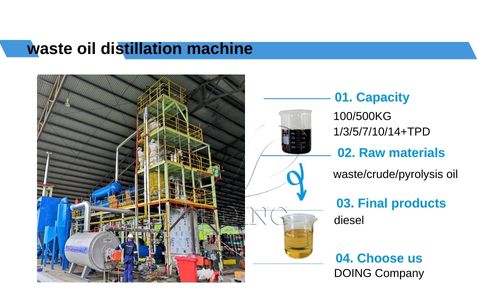

- Waste Oil Distillation Plant

- Auxiliary Equipment

Video

-

DOING Live Show - Deep Introduction to the Pyrolysis Plant

Factory Live Playback Video -

Waste Oil Sludge Treatment Pyrolysis Plant in China Operation Site Video

Project Case Video -

Fully continuous waste tire pyrolysis plant project installed by DOING introduction video

Pyrolysis Plant Video

- In Asia

- In Africa

- In Europe

- In America

- In Oceania

A:Pyrolysis is a technology used to decompose organic waste in the absence of oxygen or oxygen-deficient conditions. Oxygen-free pyrolysis is more conducive to the production of specific useful products and more environmentally friendly.

A:DOING plastic pyrolysis machine is an advanced solution for converting waste plastic into valuable resources. This plastic recycling machine can achieve high efficiency, environmental protection, and considerable benefits while processing various plastics.

A:DOING designed two types of mobile oil recycling machines: acid-base washing type and catalyst type, which converts mobile oil into diesel in 4 steps: feeding, heating, condensation, and refining.

A:DOING offers effective strategies to boost productivity in waste tire pyrolysis operations for optimizing reactor design, enhancing pre-processing, and improving product recovery can maximize efficiency and output.

Company News

Industry News