Waste tyre pyrolysis plant for sale

The process of waste tyre pyrolysis plant

Waste tyre can be converted into fuel oil through tyre pyrolysis process for environmental tyre management and tyre recycling. The most commonly used synthetic polymer used in tire production is styrene-butadiene copolymer. When the pyrolysis temperature exceeds 350 degrees Celsius, the polymer decomposes into small fuel oil and hydrocarbon gase. DOING waste tyre pyrolysis plants adopt the latest pyrolysis technology and process the waste tyres with high temperature in a oxygen-free condition. Through the waste tyre pyrolysis process, you can get fuel oil, carbon black, steel wire and combustible gas.

Waste tyre pyrolysis plant for sale and final products

Waste tyre pyrolysis plant for sale and final products

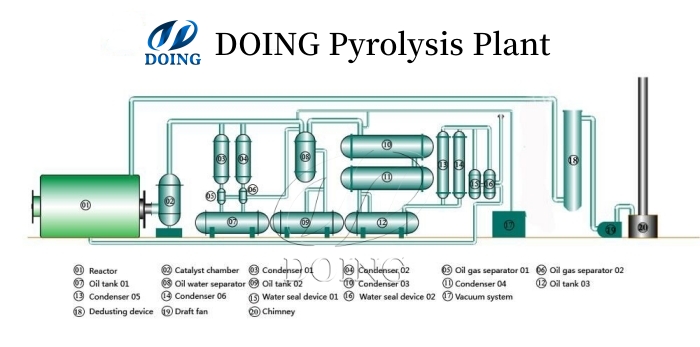

Feed the waste tyres into the pyrolysis reactor and when heated to a certain temperature, waste tyres will be cracked into oil and gas. Then through 3 steps cooling system, oil gas will be liquefied and stored in tanks. Before the next pyrolysis process starts, the carbon black will be discharged continuously. Here is the3D working process of DOING waste tyre pyrolysis plant for sale:

Waste tyre pyrolysis plant 3D working flow

Waste tyre pyrolysis plant 3D working flow

The advantages of waste tyre pyrolysis plant

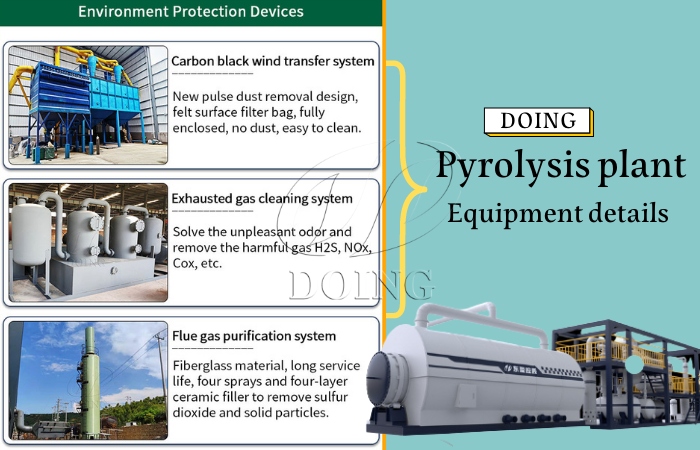

1. The comprehensive waste tyre pyrolysis plant is furnished with multiple devices. It controls the emission of smoke and smell during production and operation, effectively meeting the requirements of environmental protection.

Environmental devices of waste tyre pyrolysis plant

Environmental devices of waste tyre pyrolysis plant

2. The pressure release device operates through water circulation, which greatly improves the security of the system.

3. The release of pressure during the production dramatically increases the output within certain time and meanwhile improves the quality of oil.

4. The heating system adopts hot air heating technology, which improves the safety performance of production and heating efficiency. And the syn-gas produced in the waste tire pyrolysis process can be recycled to heat tyre pyrolysis reactor to save operation cost.

Pyrolysis gas recovery system

Pyrolysis gas recovery system

5. High efficiency fuel gas heating system. When the heated gas reaches 150 during pyrolysis process, a large amount of gas will be generated.

6. Whole tyre feed, no need to break for batch waste tyre pyrolysis plant for sale, which reduces cost. And for customers who have higher requirements for efficiency and labor-saving, we also have semi-continuous and fully automatic pyrolysis plants for sale.

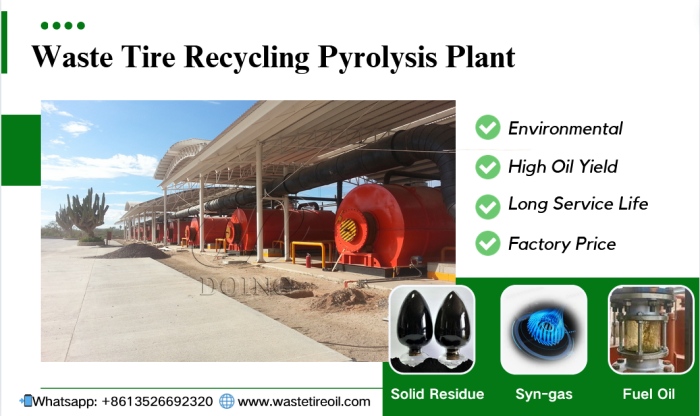

Waste tyre pyrolysis plant running site 3D drawing picture

Waste tyre pyrolysis plant running site 3D drawing picture

When it comes to transforming rubber tyre waste into valuable fuels and carbon black, selecting the appropriate pyrolysis equipment is crucial. Understanding the different types available will help you make an informed decision based on your specific operational needs and scale.

DOING waste tyre to fuel oil and carbon black pyrolysis plant

DOING waste tyre to fuel oil and carbon black pyrolysis plant

1. Batch Pyrolysis Plant(Intermittent Operation):

Features: The simplest and most common type. The reactor is loaded with used tyres, heated, cooled, and then emptied.

Benefits: Lower initial investment, ideal for smaller volumes and pilot projects, easy to operate and understand.

Considerations: Lower throughput, requires downtime between cycles for loading/unloading.

2. Semi-Continuous Pyrolysis plant:

Features: Allows for continuous feeding of scrap rubber tires while simultaneously extracting products, finishing 3 batches of pyrolysis within 2 days. The reactor may still require periodic cleaning or maintenance.

Benefits: Higher throughput than batch, reduced downtime between processing cycles, more efficient use of energy.

Considerations: More complex system design, requires careful control of feeding and discharge rates.

DOING waste tyre pyrolysis machine types

DOING waste tyre pyrolysis machine types

3. Fully Continuous Pyrolysis Plant:

Features: Operates 24/7 with constant feeding of plastic waste and continuous output of products. Often utilizes screw feeders and specialized reactor designs.

Benefits: Highest throughput and efficiency, maximized uptime, reduced labor costs per ton of processed material, consistent product quality.

Considerations: Highest initial investment, requires sophisticated automation and control systems, best suited for large-scale industrial operations.

4. Frame-Type/Ski-mounted/Mobile Type Pyrolysis Plant:

Note: “Frame-type” isn't a standard classification of pyrolysis operation. It refers to the structural design or portability of the unit.

Referring to modular/skid-mounted units: These are often designed for easy transport and installation, making them versatile for various locations and scales, and can be either batch or semi-continuous.

Referring to the overall plant structure: This is a general term that can apply to any of the operational types mentioned above, focusing on the framework supporting the reactors and peripherals.

Choosing the right type depends on your project's:

A. Capacity Requirements: How much rubber tyre/rubber powder waste do you need to process daily/annually?

B. Budget: What is your capital investment capacity?

C. Operational Expertise: What level of technical skill do you have available for operation and maintenance?

D. Location and Space: Are there any constraints on installation footprint or accessibility?

By carefully evaluating these factors against the features of each pyrolysis system, you can select the equipment that best aligns with your goals for efficient and profitable plastic waste valorization. And as a world-leading manufacturer, we have professional engineer team to custom a cost effective waste tyre recycling pyrolysis solution.

The technical parameter of DOING waste tyre pyrolysis plant for sale

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-15 | DY-10-20 | DY-15-50 |

| 2 | Raw material | Car/truck/bicycle/OTR tyres, rubber cable shealth, waste rubber sheets/carpets/soles, etc. | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 1-15 ton | 10-20 ton | 15-50 ton |

| 5 | Oil yield | Generally 30%-50%, depends on tire materials; | ||

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R/Q345R | ||

| 8 | Thickness of pyrolysis Reactor | 14/16/18/20mm | ||

| 10 | Total power | 19KW | 30KW | 35KW |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2600×6600 | 2800×7600 |

| 18 | Weight | 27T | 30T | 40T |

Prepared work for waste tyre pyrolysis plant

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

The final products of waste tyre pyrolysis plant

Instead of disposal, landfill, pile-up and other waste tire treatment methods, DOING waste tyre pyrolysis plant for sale enable the recovery of essential raw materials like pyrolysis oil, carbon black, and syngas. These can be directly reintroduced into the manufacturing supply chain, fostering a true circular economy. The daily profit margin of a 15TPD waste tyre pyrolysis plant can reach about 3609USD.

Waste tyre pyrolysis plant products

Waste tyre pyrolysis plant products

Other raw materials for waste tyre pyrolysis plant

Apart from waste tyres, waste plastics, oil sluge, coal tar residue, aluminum plastic and waste rubbers, etc. can also be used as raw materials for waste tyre pyrolysis plant to produce fuel oil and carbon black.

Waste tyre pyrolysis plant feedstock waste raw materials

Waste tyre pyrolysis plant feedstock waste raw materials

More details about the waste tyre pyrolysis plant for sale, please feel free to contact Henan Doing Company, a world leading pyrolysis plant manufacturer in China. We have professional sales team, engineer team, and installation team to customize you suitable waste pyrolysis solutions and offer one-stop services. And you are also welcome to come to our factory for inspecting our waste tyre pyrolysis plant.

Request Information

Send your inquiry for further information