Waste tyre recycling pyrolysis plant

Waste tyre recycling pyrolysis plant

First, Let's talk about "WASTE TO ENERGY" project. In one word, WTE means the process of converting waste tyre/plastic/engine oil to useful fuel oil and valuable diesel. See what can we benefit: WTE processes will make an impact on our environment and will be a quite lucrative investment! This WTE process eliminates landfills, piles of used tires, asbestos, and toxic material by converting the waste into electricity, fuel, steam, construction/highway aggregate, and a superior insulation and creates jobs.

Waste tyre recycling pyrolysis plant

Waste tyre recycling pyrolysis plant raw material :

Waste tyre recycling pyrolysis plant raw material

2.Waste plastic

3.Waste rubber

Waste tyre recycling pyrolysis plant offers following feature:

1.Generates quality fuel with lower emission

2.Controls tyre land pollution

3.Recover energy from waste tyre

4.Helps recycle carbon black

Waste tyre recycling pyrolysis plant technical data

| Technical parameter of Waste tyre recycling pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre | Waste tyre | Waste tyre |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste tyre recycling pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

Waste tyre yre recycling pyrolysis plant final product application

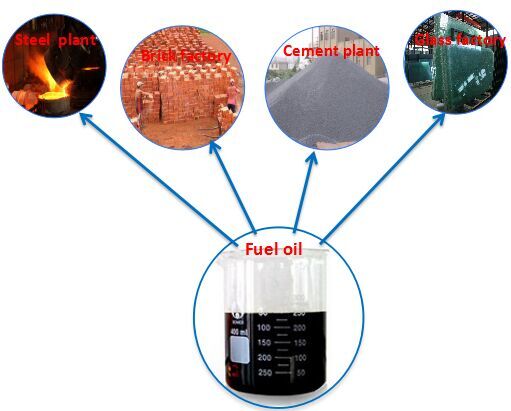

Fuel Oil (40% to 45%)

Fule oil application

Steel Wire Scrape(10% to 15%)

The third product of tyre recycling pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

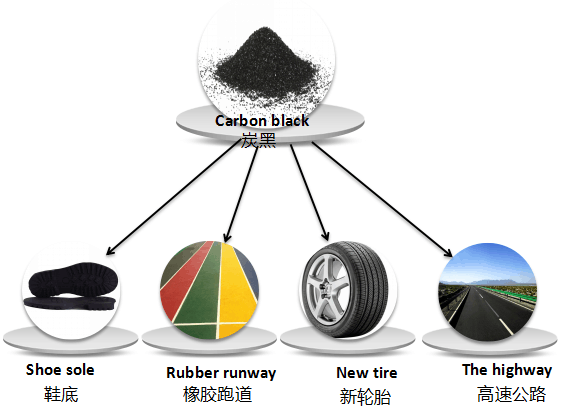

Carbon Black Powder (30% to 35%)

Carbon black application

Pyrolytic Gases (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Request Information

Send your inquiry for further information