How is pyrolysis of tyres process ?

Waste Tire/Plastic Pyrolysis Plant / Date:April 25, 2018

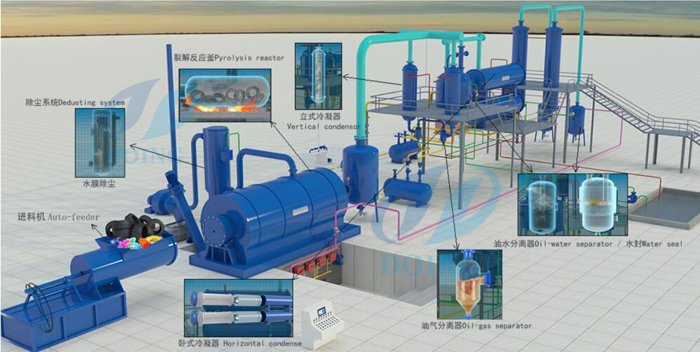

Pyrolysis of tyres process plant

Tyre pyrolysis process plant working process

The general trend is an increase in yields of liquid and gas fractions as the temperature increases. From the works devoted to tyre pyrolysis, which are focused on the generation of liquid fuel results that derived liquids are a complex mixture of organic compounds containing a lot of aromatics. This liquid can be separated into lighter and higher fractions 。

Request Information

Send your inquiry for further information