Pyrolysis plant

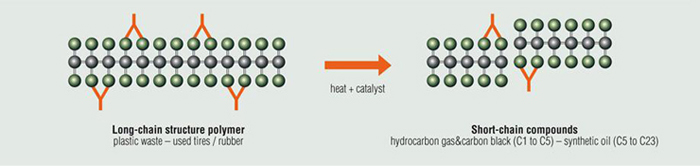

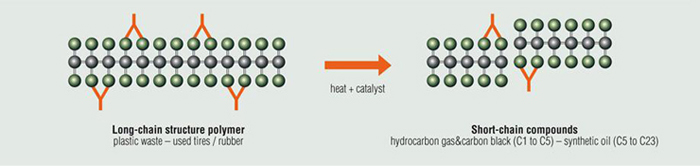

Pyrolysis plant adopts pyrolysis technology that can pyrolysis waste tyre/plastic to fuel oil ,carbon black and steel wire.

1.Slow pyrolysis

Pyrolysis plant process

Slow pyrolysis has been used for thousands of years to enhance char production at low temperatures (550-950 0 K) and low heating rates between 0.1-1 0 K/s. In this process, the vapour residence time is too high and may range between 5 min to 30 min. The components during the process are in the vapour phase which continues to react with each other resulting in formation of solid char and other liquids 6 . However, slow pyrolysis has some technological limitations which made it unlikely to be suitable for good quality bio-oil production. Cracking of the primary product in the slow pyrolysis process occurs due to high residence time and could adversely affect bio-oil yield and quality. Moreover, long residence time and low heat transfer demands extra energy input

2.Fast Pyrolysis

Pyrolysis plant

In the fast pyrolysis process, biomass is rapidly heated to a high temperature (850–1250 0 K) in the absence of oxygen and residence time between 0.5–10 s . Typically on a weight basis, fast pyrolysis produces 60%–75% of oily products (oil and other liquids) with 15%–25% of solids (mainly biochar) and 10%–20% of gaseous phase depending on the feedstock used. The production of liquids is usually yielded from biomass in a low temperature, high heating rate and short resident time environment. The basic characteristics of the fast pyrolysis process are high heat transfer and heating rate, very short vapour residence time, rapid cooling of vapours and aerosol for high bio-oil yield and precision control of reaction temperature . Fast-pyrolysis technology is receiving incredible popularity in producing liquid fuels and a range of speciality and commodity chemicals. This liquid product can be easily and economically transported and stored, thereby de- coupling the handling of solid biomass from utilization . It also has potential to supply a number of valuable chemicals that offer the attraction of much higher added value than fuels. Fast pyrolysis technology can have relatively low investme

3.Flash Pyrolysis

The flash pyrolysis of biomass is a promising process for the production of solid, liquid and gaseous fuel from biomass which can achieve up to 75% of bio-oil yield 13 . This process can be characterized by rapid devolatilization in an inert atmosphere, high heating rate of the particles, high reaction temperatures between 450 °C and 1000 °C and very short gas residence time around less than 1 s . However this process has some technological limitations, for instance: poor thermal stability and corrosiveness of the oil, solids in the oil, Increase of the viscosity over time by catalytic action of char, alkali concentrated in the char dissolves in the oil and production of pyrolytic water 。