Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>Why is DOING plastic pyrolysis plant equipped with a vacuum system?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>Why is DOING plastic pyrolysis plant equipped with a vacuum system?

Why is DOING plastic pyrolysis plant equipped with a vacuum system?

Waste Tire/Plastic Pyrolysis Plant / Date:December 29, 2020

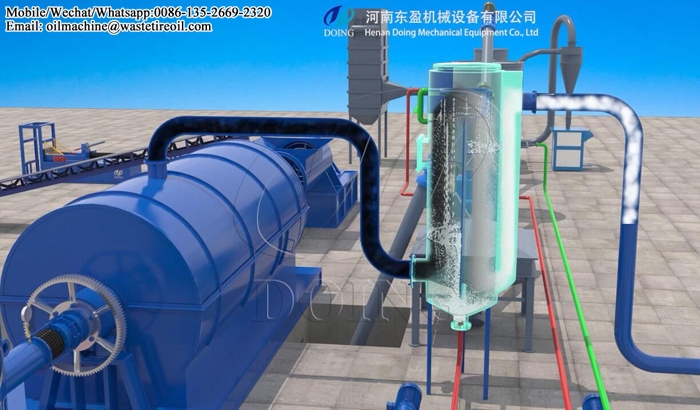

Plastic pyrolysis plant is used to make crude oil from plastic. The vacuum system can ensure the safety of the process and higher efficiency.

DOING plastic pyrolysis plant equipped with vacuum system

DOING plastic pyrolysis plant equipped with vacuum system

As we all know, waste plastics contain more or less water. Only when steam is first distilled out will the plastic produce oil gas , which means that a large amount of fuel will be wasted. With the use of vacuum system, it is not necessary to heat the temperature to 100 ℃ to evaporate the moisture in the plastic. The vacuum system creates a space below atmospheric pressure in which the moisture can be evaporated at less than 100℃. The negative pressure can accelerate the evaporation of plastic moisture during the preheating of plastics, shorten the time of plastic pyrolysis process and save fuel.

The waste plastics containing water to be processed by plastic pyrolysis plant

The waste plastics containing water to be processed by plastic pyrolysis plant

After the plastic pyrolysis process is completed, it is necessary to open the feed door of the reactor, cool the reactor and discharge the carbon black. However, due to the large space in the reactor, some of the oil gas cannot flow into the cooling system. If the reactor door is opened without removing all oil gas, a large amount of high temperature oil gas will come out from reactor, it is very dangerous to operators. Therefore, the oil gas retained in the reactor need to be removed before the feed door is opened. In addition, the presence of oil gas will keep the temperature of the reactor at a high level, resulting in a longer cooling time of the reactor.

Cooling the reactor to a certain temperature before open the feed door

Cooling the reactor to a certain temperature before open the feed door

At this point, all the above problems can be solved by opening the vacuum system. The vacuum system will generate a pressure space below the atmosphere. At this time, the oil gas in the reactor will slowly flow to the cooling system due to the pressure difference, so that the oil gas in the reactor will be completely cooled down, and after a while you can open the reactor door and discharge carbon black safely. Subsequently you can start the second plastic pyrolysis process.

Oil gas remained in the reactor flows into the cooling system with the use of vacuum system

Oil gas remained in the reactor flows into the cooling system with the use of vacuum system

Vacuum system is vitally important to plastic pyrolysis plant. Besides the vacuum system, we DOING company have a lot of other sophisticated designs for plastic pyrolysis plant, welcome to contact with us to know more.

Request Information

Send your inquiry for further information