Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>How to increase output of waste tyre pyrolysis plant?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>How to increase output of waste tyre pyrolysis plant?

How to increase output of waste tyre pyrolysis plant?

Waste Tire/Plastic Pyrolysis Plant / Date:August 31, 2019

The oil yield of waste tyre is between 40%-50% depending on different types of tyre, but how to increase the output of waste tyre pyrolysis plant and make the tyre oil yield more close to 50% rather than just around 40%?

I believe this question is most concerned by waste tyre pyrolysis plant users.

From our long-term practice, we get 4 basic methods which is very helpful for our customers to increase the oil output, and they are as follows.

1. Choosing waste tyre with good oil yield

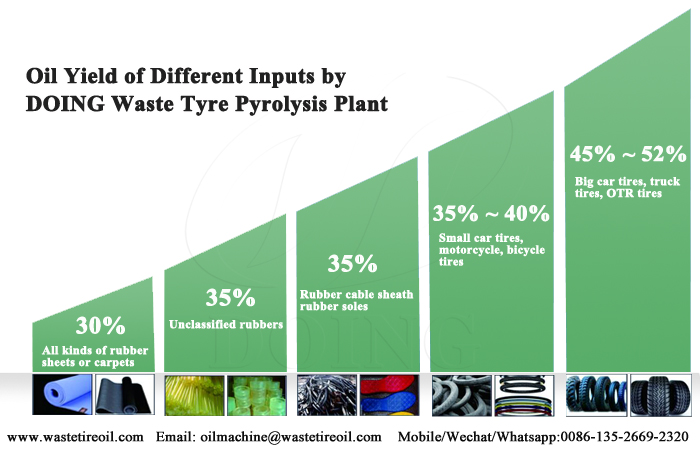

As we know, tyre has different types. Normally radial tyre has higher oil yield than nylon tyre, and big truck tyre has higher oil yield than small tyres from car and bicycle, etc. So you can increase output of the waste tyre pyrolysis plant by controlling the raw material.

Oil yield of different tyres

Oil yield of different tyres

2. Try to feed more tyre

For same waste tyre pyrolysis plant, if you wanna feed more tyre, you can change the form of waste tyre by cutting or shredding work, or double/triple pack waste tyre to fully take advantage of the space inside the pyrolysis reactor, or feed tyre with the help of hydraulic auto-feeder.

Tyre shredder for tyre fragment

Tyre shredder for tyre fragment

3. Well control the pyrolysis temperature

To get good oil recovery, it is very important to operate the pyrolysis plant under suitable temperature, which can ensure oil gas get thoroughly condensed inside the cooling system. If temperature too low, the tyre cannot fully pyrolyzed, to say nothing of high oil output. Similarly, if temperature too high, oil gas will run out of cooling system as the tail gas, then oil output will also have discount.

Tyre pyrolysis reactor

Tyre pyrolysis reactor

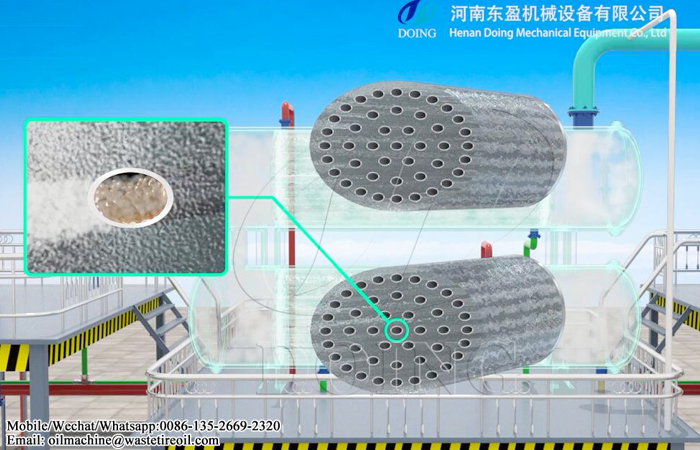

4. Choose a waste tyre pyrolysis plant with reasonable cooling system

Most of time, cooling effect of the waste tyre pyrolysis plant will greatly affect its oil output. It is not difficult to judge if the cooling effect of a pyrolysis cooling system is good or not, just calculate its heat exchanging area is ok. For e.g., by calculation, the heating exchanging area of our waste tyre pyrolysis plant cooling system is 1.5times the area needed to completely cooling down the oil gas produced from the full-load pyrolysis reactor.

DOING special tube-type cooling system for better cooling effect

DOING special tube-type cooling system for better cooling effect

But if you have want to start a waste tyre pyrolysis plant with higher output, please contact with us at any time. We’ll be glad to discuss with you on this matter.

Request Information

Send your inquiry for further information