Waste plastic recycling pyrolysis plant

Pyrolysis

Pyrolysis

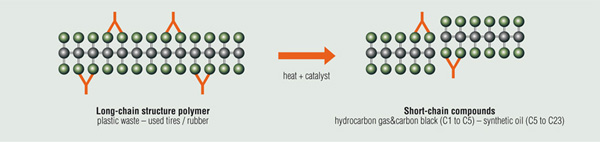

What is pyrolysis:

Pyro = heat. Lysis = break down.

Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

Waste plastic recycling pyrolysis plant

Waste plastic recycling pyrolysis plant

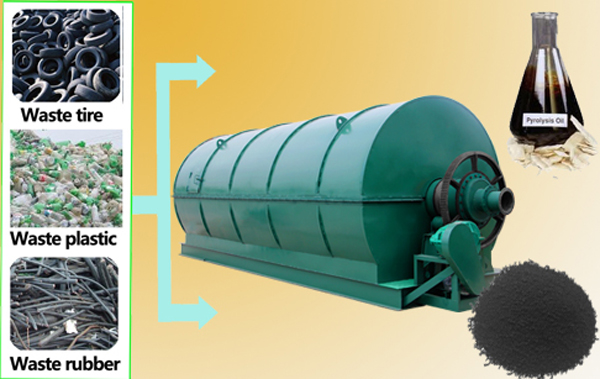

Plastic pyrolysis is: the process of converting waste plastics into industrial fuels like plasitc pyrolysis oil, carbon Black, hydrocarbon Gas.

Plastic pyrolysis

Plastic pyrolysis

Plastic pyrolysis is a thermo decomposition of plastic polymer, since waste plastic are long chain polymers containing more than 50,000 carbon atoms attached to each other in a cross linked or straight chain.

All kinds waste plastic products in our daily life

All kinds waste plastic products in our daily life

Plastic products has been used widely, and waste plastic can be seen everywhere. It has seriously affected our environment on two aspects, such as visual pollution and potential hazards. Visual pollution means that aesthetic perception on living city affected by scrap plastic in everywhere.

Waste plastic harm to animals

Waste plastic harm to animals

Potential hazards mainly refers to degradation-resistant of waste plastic affecting on absorbing of nutrients and water by crop, reducing the production; and otherwise, animals will be die if eats it unconscious. Recycling and utilization of waste plastic is increasingly becoming an important aspect for environmental protection. Waste plastic recycling pyrolysis plant has supplied a new solution on disposal of waste plastic.

So is this new waste plastics processing solution easy to implement? Henan Doing Mechanical Equipment Co., Ltd's waste plastic recycling pyrolysis plant is very user-friendly and easy to operate. The specific plastic to oil process is as follows:

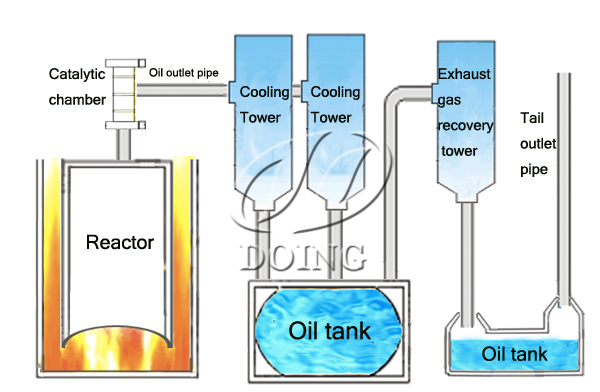

Waste plastic recycling pyrolysis plant process

Waste plastic recycling pyrolysis plant process

When using this waste plastic recycling pyrolysis plant to dispose waste plastics, the pre-treated plastics will firstly be conveyed to the moving horizontal pyrolysis reactor through feeder system. Then the plastics will take a series of pyrolysis reactions under the action of catalyst. Finally we can get pyrolysis oil and carbon black. Both of them are available energy.

Final products from waste plastic recycling pyrolysis plant

Final products from waste plastic recycling pyrolysis plant

For example, the plastic pyrolysis oil can be widely used as fuel oil in industries such as steel and iron and boiler factories, ceramics, power or chemical industries or hotels, restaurants etc. or used for generators to get electricity. The carbon black can be used for making construction bricks with clay, or used as fuel.

Waste plastic recycling pyrolysis plant technical data

| Technical parameter of waste plastic recycling pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste plastic recycling pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

Waste plastic recycling pyrolysis plant final product and application

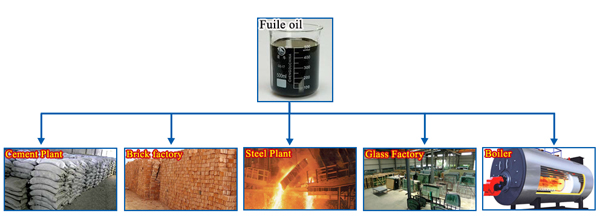

After processed by waste plastic recycling pyrolysis plant, you can get fuel oil and carbon black. The following are the function of products from waste plastic recycling pyrolysis plant.

Fuel oil application

Fuel oil application

Fuel oil:The main product-fuel oil produced by our waste plastic pyrolysis plant is widely used for industrial and commercial purposes.With the heating value 10592.48 Lcal/Kg,this fuel oil is a kind of good heating fuel which can be applied for boiler factory,cement factory,glass factory and steel mill,ect.

Carbon black application

Carbon black application

Carbon black:Is used as raw material or main ingredient in many industries and the chemical structure of carbon black strengthens,lengthens the endurance,and improves the coloring features of the materials.It is more price-efficient to be used as an ingredient listed.

Waste plastic recycling pyrolysis plant project cases

Waste plastic recycling pyrolysis plant project cases

So far, Henan Doing Machinery Equipment Co., Ltd.'s waste plastic recycling pyrolysis planthas successfully installed and operated in more than 50 countries and regions, such as Italy, Macedonia, Iran, Egypt, Mexico, Ecuador, Haiti, Congo, Uganda, Nigeria, India, Pakistan, Thailand, Malaysia. , Bangladesh, Guatemala and other parts of the world, by domestic and foreign customers alike, is your best choice for investing in waste plastic recycling pyrolysis plant!

Request Information

Send your inquiry for further information