Is fully automatic tyre pyrolysis plant profitable?

Industry News / Date:January 13, 2020

Fully automatic tyre pyrolysis plant, as its name implies, is a pyrolysis plant that can work and produce automatically. It a high profitable project. According to customer feedback, for a 30-ton fully-automatic device, a daily income of $ 1,850 can be obtained.

Fully automatic tyre pyrolysis plant for recycling waste tyre to treasure

Fully automatic tyre pyrolysis plant for recycling waste tyre to treasure

This fully automatic tyre pyrolysis plant is designed based on the batch type tyre pyrolysis plant. As we all know, when batch pyrolysis plant is used to process waste tires, the entire tire can be directly placed in the reactor for processing. Generally, a batch can be processed within 24 hours. After the batch plant has processed a batch, the plant needs to be stopped and discharged. The second batch of processing cannot begin until the carbon black is cleaned.

Batch type waste tyre pyrolysis plant

Batch type waste tyre pyrolysis plant

When batch plant is used to process waste tires, the entire tire can be processed. The plant cost is low, but the processing capacity is limited. Generally, a reactor can only process 10 to 15 tons of waste tires, and the number of manual labor is large, usually one batch pyrolysis plant requires 6 workers to operate. In addition, the processing time of each batch is generally about 20-24 hours. In order to solve the above problems, a fully automatic tyre pyrolysis plant was created.

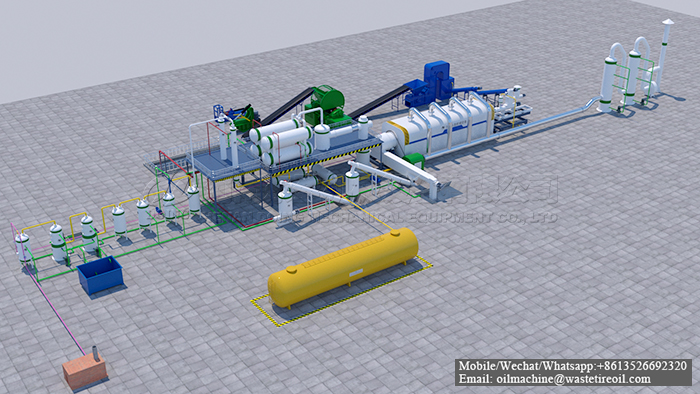

3D drawing of DOING fully automatic tyre pyrolysis plant

3D drawing of DOING fully automatic tyre pyrolysis plant

Fully automatic tyre pyrolysis plant can achieve large processing capacity. Generally, the automatic equipment processing capacity is 30 tons, 50 tons or even 100 tons. And the equipment can run automatically for one month without stopping. In addition, the PLC control system can be used for fully automatic equipment, and only 2 people can operate the entire machine.

Our customer's fully automatic tyre pyrolysis plant project

Our customer's fully automatic tyre pyrolysis plant project

Generally, customers need to purchase rubber powder as a raw material for fully automatic equipment. The price of one ton of rubber powder in the market is 150-170 US dollars. One ton of rubber powder can produce 55% of fuel oil and 45% of carbon black. The market price of one ton of fuel oil is US $ 420, and the market price of one ton of carbon black is US $ 40.

From this we can get the following table of 30 tons of fully automatic tyre pyrolysis plant profit:

| Cost | ||

| 1. Rubber powder | 170 USD*30T=5100 USD | Total cost: 5620 USD |

| 2. Fuel for heating | 420USD*1T=420 USD | |

| 3. Electricity consumption | 100 USD | |

| 4. Workers’ salary | ||

| Profit | ||

| 1. Fuel oil | 420USD*16.5T=6930 USD | Total profit: 7470 USD |

| 2. Carbon black | 40USD*13.5T=540 USD | |

| Total net profit | 7470 USD - 5620 USD = 1850 USD | |

Request Information

Send your inquiry for further information