Home > News > Industry News>Does your tire pyrolysis machine produce any waste? How to deal with it?

Home > News > Industry News>Does your tire pyrolysis machine produce any waste? How to deal with it?

Does your tire pyrolysis machine produce any waste? How to deal with it?

Industry News / Date:January 11, 2020

Nowadays, Pyrolysis tech is more commonly used in waste tire recycling compared with the way of tire re-treading and tire to reclaimed rubber because of the good benefits it brings.

Waste tire pyrolysis machine

Waste tire pyrolysis machine

But with the increasing environmental standards in most areas of the world, more and more of our customers who want to set up a waste tire pyrolysis machine are starting to care if this machine will produce any waste during the pyrolysis process, so in this article, let's see what kind of waste is produced from our waste tire pyrolysis machine and how we we deal with it.

Extra Syn-gas and smoke from the pyrolysis reactor furnace are the main wastes produced from our waste tire pyrolysis machine.

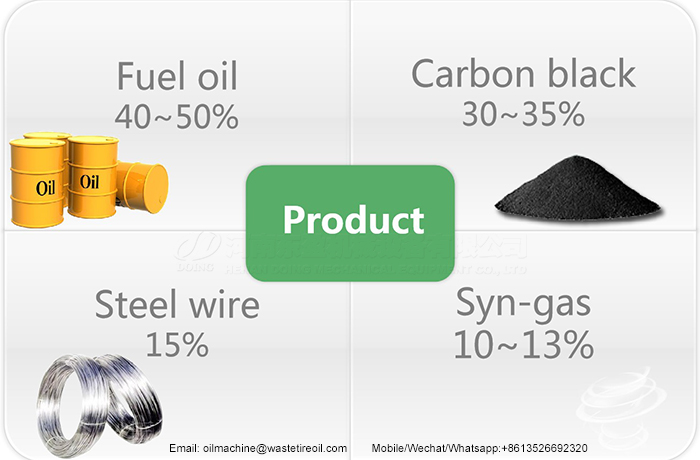

Our waste tire pyrolysis machine has higher oil output and working efficiency, it can greatly convert waste tire into about 40-50% heating fuel, 30-35% tyre carbon black, 12-15% steel wire and 10-13% syngas, among which fuel oil, carbon black and steel wire are the commercial products and do not belong to the waste, syn-gas is mostly recycled as fuel to heat the pyrolysis reactor, so the waste is only the extra syn-gas and the smoke produced by the burning of extra syn-gas and the heating fuel of pyrolysis reactor.

The end products of waste tire pyrolysis machine

The end products of waste tire pyrolysis machine

How to deal with the Extra Syn-gas?

There are sulfide, fluorid and chloride inside the extra syn-gas, among which H₂S is poisonous and with bad smell. Our smell disposal system can effectively remove sulfide, fluorid and chloride as well as H₂S from excess uncondensable gas and guarantee no pollution from excess gas burning.

Smell disposal system

Smell disposal system

How to deal with the Smoke?

Our gas(smoke) desulfuration scrubber is specially used to rinse the smoke. As the picture shows, the flue gas after combustion enters the flue gas scrubbing system. The two scrubbing towers are filled with high-efficiency desorption purifying agent. The agent has strong adsorption capacity, fast adsorption speed, fast desorption speed, easy regeneration, and can remove various pollutants and solid particles in the flue gas; make CL2, CO, CO2, SO2, SO3, NOX, CS2 controlled to a reasonable degree.

Flue gas cleaning system

Flue gas cleaning system

However, to completely remove the waste produced by the waste tire pyrolysis machine is not easy, which needs a good tech and rich experience in the pyrolysis industry. We have successfully run our waste tire pyrolysis machine in more than 70 countries, you are welcome to contact with us for more project information.

Request Information

Send your inquiry for further information