How to extract furnace oil from old tyres?

Industry News / Date:May 20, 2020

At present, with the rapid development of the world's automobile industry and transportation, the amount of waste tires, waste plastics, waste rubber is increasing, resulting in more and more serious pollution problems, governments are trying to solve this thorny problem. Extracting furnace oil from the old tyres is the best way to solve this problem. Because it not only avoids serious pollution, but also profits. Then how to extract furnace oil from old tyres?

Extract furnace oil from old tyres

Extract furnace oil from old tyres

Currently, the furnace oil extracted from waste tyres on the market is mainly used for tyre pyrolysis plant. The following are the main operation steps of extracting furnace oil from old tyres with the tyre pyrolysis plant.

Main operating steps of extracting furnace oil from old tyres

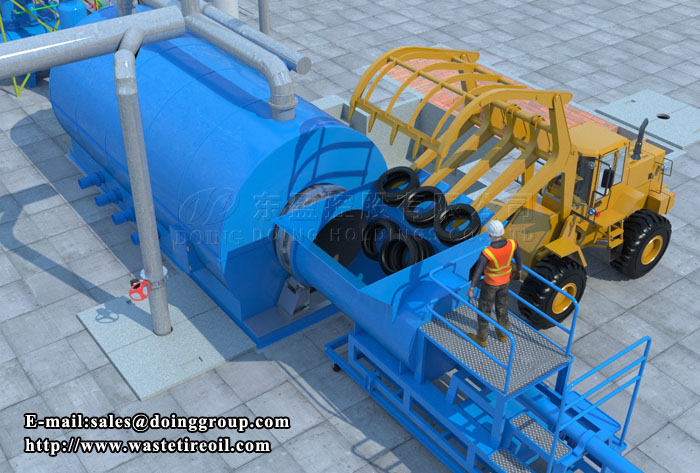

1. Feeding

Open the furnace door of the tyre pyrolysis reactor and feed the old tyres into the pyrolysis reactor with an automatic feeder. After loading the old tyres, close the door of the feed inlet and slag outlet to ensure that the furnace door is closed.

Old tyres feed

Old tyres feed

2. Heating

Turn on the rotating speed machine to make the pyrolysis reactor rotate and be heated uniformly. At the same time, the burner is turned on and the pyrolysis reactor is heated. In the process of heating the pyrolysis reactor, the thermometer shall be checked and the temperature shall be recorded. After reaching a certain temperature, the old tyres begins to crack, producing oil gas. When heated to 200-300 degrees continuously, it is the most and the fastest stage oil gas production.

Heating pyrolysis reactor

Heating pyrolysis reactor

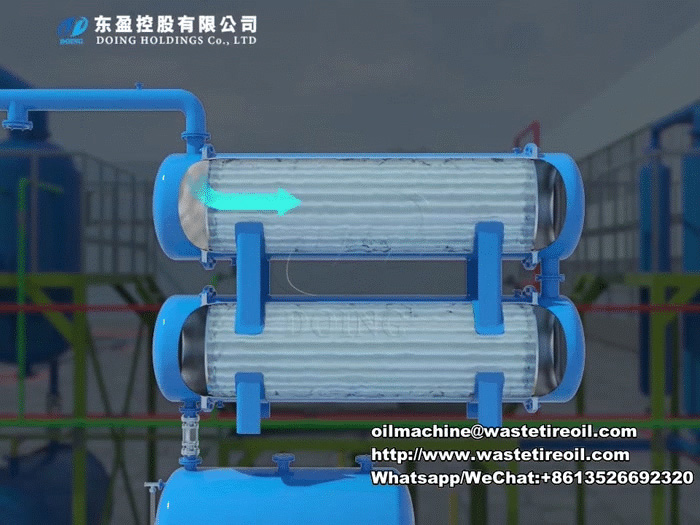

3. Cooling

Oil gas flowing through the cooling system will be liquefied into liquid oil, and some of the non-condensable can be used to heat the pyrolysis reactor. At the end of the pyrolysis process, all the combustors should be shut down. After the temperature drops to about 150 ° c, the heating should be stopped, the machine should be shut down, and the cooling reactor of the cooling system should be turned on. The cooling system of the reactor is at the top of the reactor, and the temperature of the reactor can be lowered by pumping air into the reactor.

Cooling oil gas

Cooling oil gas

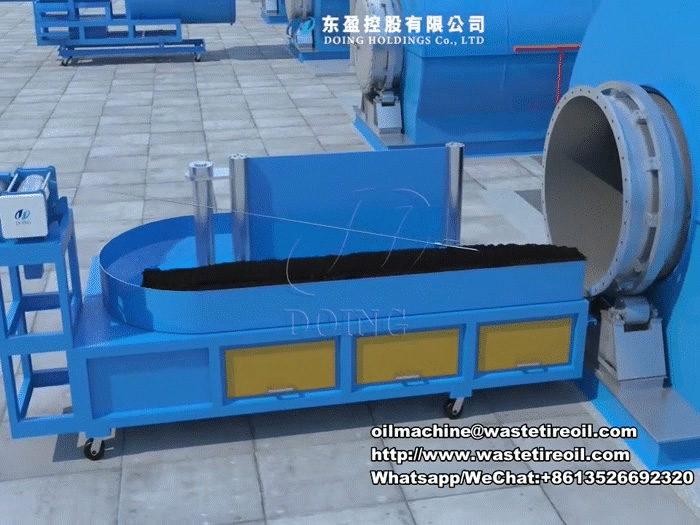

4. Slagging

Turn on the rotating machine, then turn the reactor counterclockwise. Open the carbon black slag discharge port, then collect the carbon black through the carbon black hoist into the carbon black bag. After the carbon black is collected, open the furnace door and pull out the wire with a wire-drawing cart.

Slagging carbon black

Slagging carbon black

Through a series of operations above, we extracted furnace oil from the old tyres by tyre pyrolysis plant. This not only solved the pollution caused by old tyres. The fuel oil, carbon black and steel wire obtained from the old tyres can also obtain certain economic benefits. This is currently the most ideal old tyres solution.

Request Information

Send your inquiry for further information