New way waste oil recycling to diesel machine

Waste Oil Distillation Plant / Date:04-01-2017

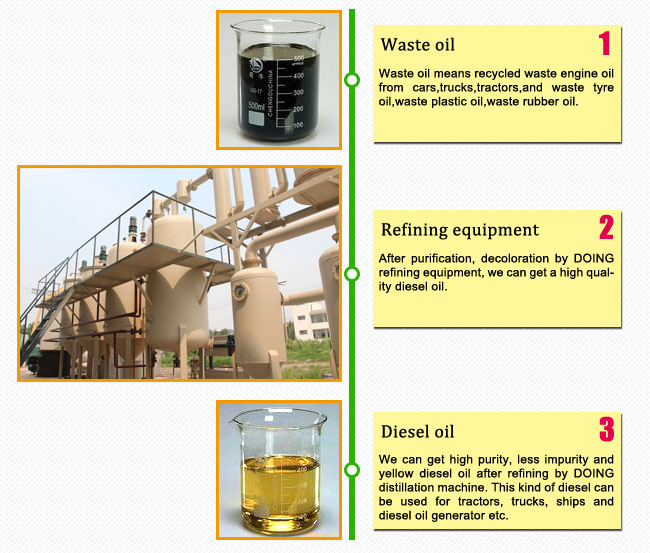

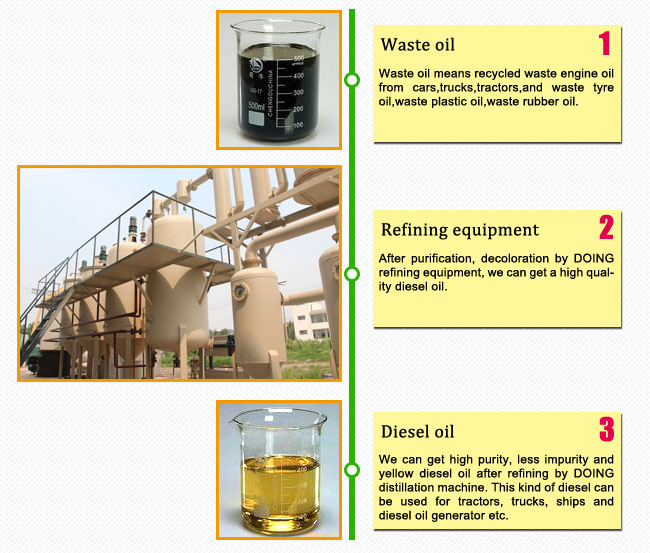

New way waste oil recycling to diesel machine adopting the refining or distillaion technology,Doing produced waste oil recyling to diesel machine can be widely used in refining tyre pyrolysis oil ,plastic pyrolysis oil ,and other kinds of pyrolysis oil into qualified diesel fuel.

Working process of new way waste oil recycling to diesel machine:

Waste oil recycling to diesel machine process

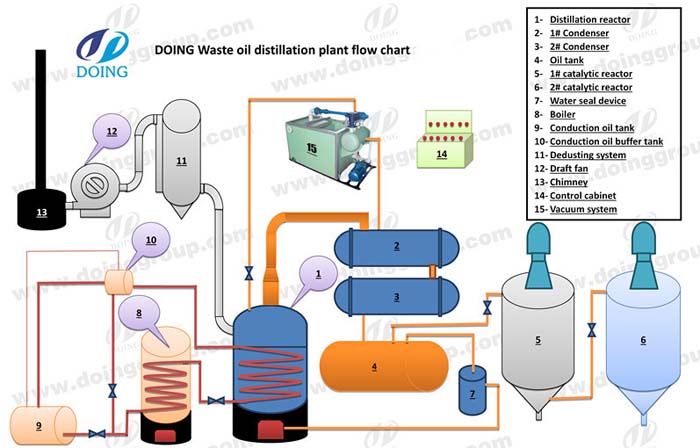

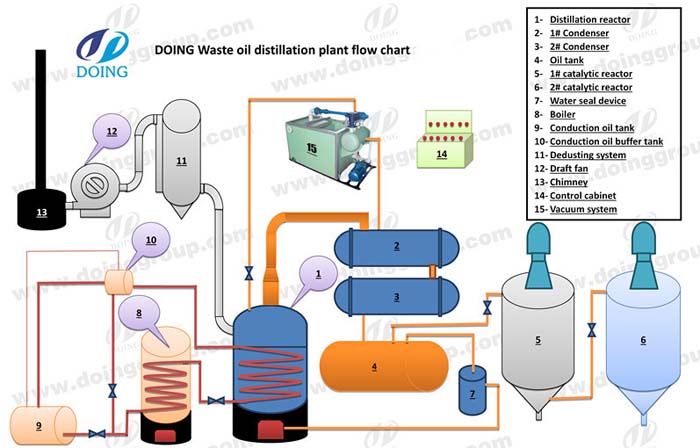

a. Pump the waste oil into reactor by oil pump.

b. Use coal/wood/natural gas/fuel oil/electricity heating the reactor.

c. After heating some time, the liquid oil will become oil gas, oil gas will be liquefied by the cooling pipe and condensers then will go into oil tank. Here we get mixed oil, or u can also call it fuel oil. If you wanna get a different quality diesel separately, through temperature control could separate it and collected into two different oil tanks.

d. Some gases (syngas) like Methane, Ethane, Propane, Butane, and Hydrogen cannot be liquefied under normal pressure and normal temperature will be recycled to fire furnace heating the reactor.

e. When use burning material heating the reactor, will produce some smoke. These smokes will go into our de-dusting system, the inside we design some high pressure nozzles, these nozzles will spraying some chemical water, the dust will be absorbed by the chemical water and flowing into the de-dusting pool. In the pool we will put some chemical which could remove the sulfur.

f. The exhaust gas will go into the chimney sucked by draft fan, when emission the exhaust gas will become steam, no pollution.

Advantages about waste oil recycling to diesel machine

1. The complete set of unit produces no smoke and smell with favorable effects of environmental protection.

2. The pressure release device operates through water circulation, which greatly improves the security of the system.

3. The release of pressure during the production dramatically increases the output within certain time and meanwhile improves the quality of oil.

4. The heating system adopts indirect heating technology, which prolongs the machine service life; the average life time is about 7 years.

New way waste oil recycling to diesel machine can purify waste tire oil, plastic oil; waste engine oil to diesel, the final product-diesel can be used for tractors, trucks, and diesel oil generators, ships etc.

Working process of new way waste oil recycling to diesel machine:

Waste oil recycling to diesel machine process

b. Use coal/wood/natural gas/fuel oil/electricity heating the reactor.

c. After heating some time, the liquid oil will become oil gas, oil gas will be liquefied by the cooling pipe and condensers then will go into oil tank. Here we get mixed oil, or u can also call it fuel oil. If you wanna get a different quality diesel separately, through temperature control could separate it and collected into two different oil tanks.

d. Some gases (syngas) like Methane, Ethane, Propane, Butane, and Hydrogen cannot be liquefied under normal pressure and normal temperature will be recycled to fire furnace heating the reactor.

e. When use burning material heating the reactor, will produce some smoke. These smokes will go into our de-dusting system, the inside we design some high pressure nozzles, these nozzles will spraying some chemical water, the dust will be absorbed by the chemical water and flowing into the de-dusting pool. In the pool we will put some chemical which could remove the sulfur.

f. The exhaust gas will go into the chimney sucked by draft fan, when emission the exhaust gas will become steam, no pollution.

Advantages about waste oil recycling to diesel machine

1. The complete set of unit produces no smoke and smell with favorable effects of environmental protection.

2. The pressure release device operates through water circulation, which greatly improves the security of the system.

3. The release of pressure during the production dramatically increases the output within certain time and meanwhile improves the quality of oil.

4. The heating system adopts indirect heating technology, which prolongs the machine service life; the average life time is about 7 years.

| Technical parameter of waste oil recycling to diesel machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

New way waste oil recycling to diesel machine can purify waste tire oil, plastic oil; waste engine oil to diesel, the final product-diesel can be used for tractors, trucks, and diesel oil generators, ships etc.