Waste oil refining to diesel fuel machine

Waste Oil Distillation Plant / Date:01-30-2018

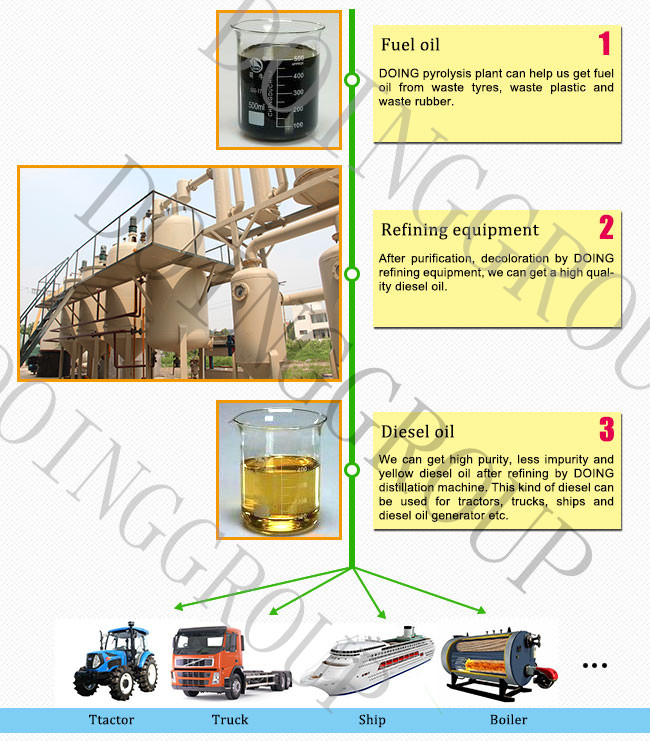

Waste oil refining to diesel fuel machine can convert tire oil, plastic oil, and waste engine oil to diesel. In some country, waste oil refining to diesel fuel machine also named waste oil distillation machine, distillation equipment, it just name different, but have a same functions.

Waste oil refining to diesel fuel machine

We have 5t-50t per day waste oil refining to diesel fuel machine, can meet different customer’s requirements.

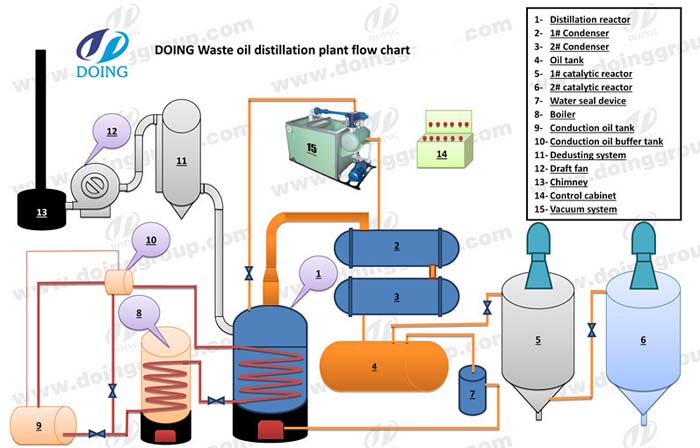

DOING 5T/D tire waste oil refining to diesel fuel machine is mainly composed of 4 reactors, cooling system, vacuum system, filtering system and de-dusting system. Our waste oil refining to diesel fuel machine can refine waste tire oil into diesel very efficiently, and at the moment it is the most energy-saving refinery equipment in the market.

Waste oil refining to diesel fuel machine working process

Waste oil refining to diesel fuel machine

2. Heat the reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out first by controlling the temperature over 150 Celsius degrees.

3.The gasoline will be cooled out when the temperature is below 150 Celsius degrees, the rest of the system is same as pyrolysis system.

Waste oil refining to diesel fuel machine features:

Waste oil refining to diesel fuel machine

- After 2 years’ research and development, our refining technology is already mature.

- Can refine 3 kinds of oil--waste tire oil, plastic oil and waste motor oil.

- The final oil can be directly used for diesel oil generator, trucks and vans, etc.

- Indirect heating by boiler heating system can greatly increase the service life of our waste tire waste oil refining to diesel fuel machine.

- Three steps purifying process ensure final diesel pure and high quality

Technical parameter of waste oil refining to diesel fuel machine:

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | Waste engine oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 85% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 9kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Diesel fuel application

Diesel from waste oil refining to diesel fuel machine can be used for tractors, trucks, ships and diesel oil generators etc. below is the different waste oil with its oil rate.

| Oil yield of different material | ||

| No. | Name | Oil recovery rate |

| 1 | Waste tire oil | 85%-90% |

| 2 | Waste plastic oil | 95% |

| 3 | Waste engine oil | 85%-90% |