Waste oil disposal plant

Waste Oil Distillation Plant / Date:12-10-2016

Waste oil

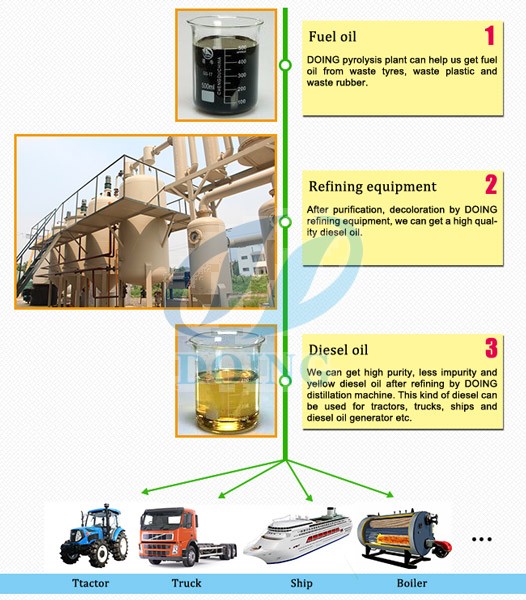

Disposing of used oil the wrong way has the potential to pollute land, water and infrastructure, so we need to recover and recycle as much of it as possible. Consider that it takes only one litre of oil to contaminate one million litres of water and a single automotive oil change produces 4 to 5 litres of used oil.

Although it gets dirty, used oil can still be cleaned and re-used. In fact, recycled used oil can be used as an industrial burner fuel,

hydraulic oil, incorporated into other products or re-refined back into new lubricating oil.

Waste oil disposal plant

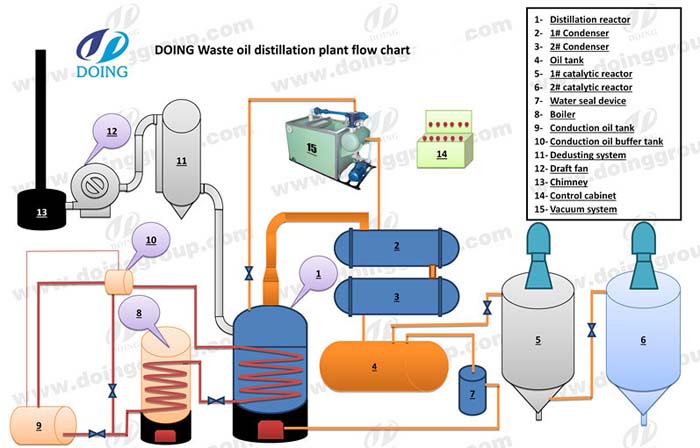

Waste oil disposal plant working process

Waste oil disposal plant working process

1. Prepare waste crude oil

2. Heating for distillation

3. Cooling

4. Chemical process for cleaning the distillation oil

5. Collect final diesel product

Waste oil disposal plant advantage

Waste oil disposal plant waste installed in Mexico

By using the heat transfer heating system, our client can save much fuel to heat the whole reactor, and the heating speed is faster and the temperature can keep the reactor hot for longer time,so the whole process is faster with less fuel

2: The heating circulation system is more environmental

All the heat transfer system is a circulating system, the heat transfer oil is recycling inside the reactor. So in total, you can fire less fuel, which not only save your cost on fuel also it is more environmental-friendly. All the system is sealed, in the terms of smoke and smell, our new design Used oil refining plant workers better.

3:The vertical reactor

From our design,It is very easy to clean the slag , it will be down through the bottom of the vertical reactors. So the operation is easier

4: Continuously working

When operating the machine,first you pump oil inside the reactor to heat,after finishing heating,it will becoming oil gas and goes to cooling system,then go to another tank.So,the first reactor is empty,no need to stop,you could pump another tank of oil again into the first tank ,continuously working.

Waste oil disposal plant technical data

| Technical parameter of Waste oil disposal plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

Waste oil disposal plant final product and application

Waste oil disposal plant can used for tractors ,trucks,ships and generator :

Diesel application