Crude oil to diesel refining process plant

Waste Oil Distillation Plant / Date:12-10-2016

Crude oil to diesel refining process plant

The refining process of crude oil is more and more necessary for our earth because of environment pollution. The crude oil to diesel refining process can convert crude oil into diesel, and the diesel through distillation has higher value and more expensive price.

Crude oil to diesel refining process plant working process

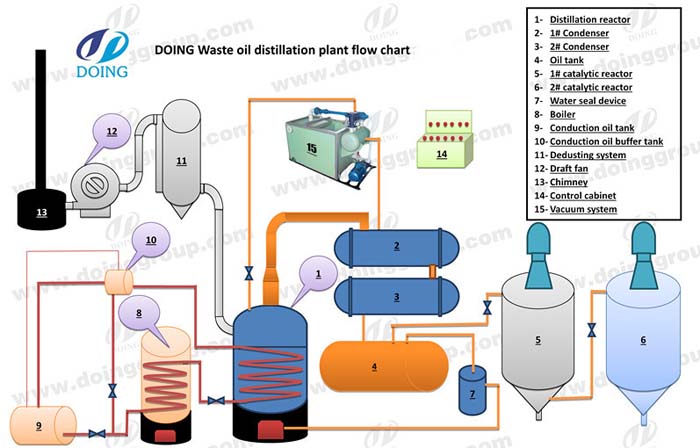

About the Crude oil to diesel refining process plant, it is equipped with latest tubular heating system, which enables material oil get heated while flowing. There is also advanced preprocess tank removing impurities and water firstly before hot oil get into distillation reactor. In the distillation process of crude oil, when heating the reactor, you can use oil, LPG, nature gas, wood and coal as heating material. Generally, 1 ton raw material oil needs 30-40 KG coal as fuel. The average oil output rate can reach 80%-90% (relies on different material oil).

The Crude oil to diesel refining process plant has two biggest advantages:

Crude oil to diesel refining process plant

Environmental protection

1. In the dedusting system, three steps are used to dedust the hot smoke from reactor, which ensures the released gas is pollution-free2. The exhaust gas will be directly recycled for heating reactor, no gas pollution3. All parts are well-sealed, so air leakage can be avoided.

Safety

1. Hydroseal and Vacuum system will prevent exhaust gas from going back to condensers and reactor.

2. Equipped with thermometer, pressure gauge, safety valve and electric control system.

Technical data of crude oil to diesel refining process plant

| Technical parameter of crude oil to diesel refining process plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

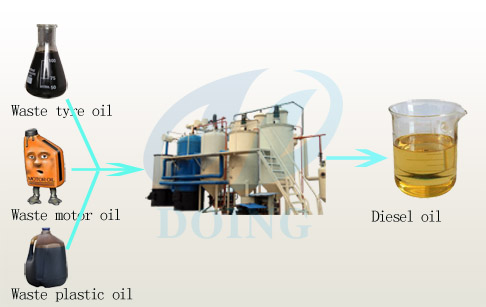

| Raw material | rubber oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

DOING crude oil to diesel refining process plant can purify waste tire oil, plastic oil, waste engine oil, the final diesel can be used for tractors, trucks, and diesel oil generators, ships etc

.

Diesel application