Waste tyre pyrolysis to oil plant

Tyre pyrolysis oil

Waste tyre pyrolysis to oil plant

Waste tyre pyrolysis to oil plantWaste tyre pyrolysis plant to oil technology is mainly to convert the waste plastic/tyre to crude oil. Also called waste tyre recycling plant, waste tyre recycling machine, waste tyre and so on. Usually there are two machines used together. The waste tyre pyrolysis plant to oil can convert the waste plastic/tyre to tyre oil (also named plasticoil). Then the curde oil distillation machine will convert the crude oil (plasticoil, tireoil) into diesel oil. In this step the oil is of great quality can used directly for car, motor, and bus and so on. Among all the advantages the raw material of the waste tyre pyrolysis plant to oil is easily achieved and cheap. Thus making the equipment much profitable.

The waste tyre pyrolysis to oil plant:

Waste tyre pyrolysis to oil plant

.

Waste tyre pyrolysis to oil plant technical parameter

| Technical parameter of Waste tyre pyrolysis to oil plant | ||||

|---|---|---|---|---|

| Items | Contents | |||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyre ,waste rubber,waste plastic, | ||

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

Waste tyre pyrolysis to oil plant final product

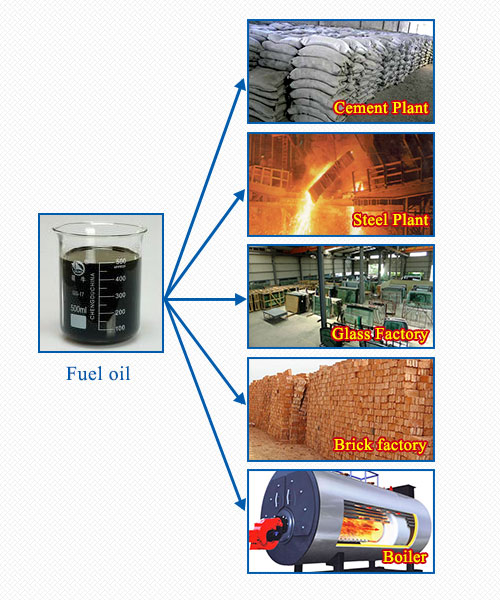

1. Fuel oil (45%-52%): Oil from waste tyre pyrolysis to oil plant can be used as industrial fuel for burning.

Fuel oil application

2. Carbon black (30%): First, Carbon black from waste tyre pyrolysis to oil plant is crude oil . You can sell it to the brick factory as internal combustion or to the factory which need it as raw materials, such as shoe, tire, cable and sealant companies. Second, could make further process, make carbon black powder into carbon black briquette, and use it for burning.

4. Waste gas (5%): we have a special design could recycling it into fire furnace for burning.

Request Information

Send your inquiry for further information