Sale waste tire and plastics pyrolysis plant

Waste tire and plastics pyrolysis plant

What is pyrolysis:

Pyro = heat. Lysis = break down.

Pyrolysis is chemical reaction. This reaction involves molecular breakdown of larger molecules into smaller molecules in presence of heat. Pyrolysis is also known as thermal cracking, cracking, thermolysis, depolymerization, etc.

The waste tire and plastics pyrolysis plant is mainly to convert the waste plastic or tyre into crude oil for fuel. Recently years the technology pyrolysis plant is consistently developing.From the waste tire and plastics pyrolysis plant to the final product of the pyrolysis plant. Many aspects of the pyrolysis plant are advancing. We henan doing mechanical equipment co,ltd made many innovations of the pyrolysis plants. pyrolysis plant is fast developing under the time of sustainable development. And the pyrolysis technology will surely be popular in the future.

The waste tire and plastics pyrolysis plant raw material

Waste tire and plastics pyrolysis plant raw material

2.Waste plastic

3.Waste rubber

The waste tire and plastics pyrolysis plant which has been improved has the advantages as follow:

Waste tire and plastics pyrolysis plant advantage

- First we need professional technicians to install the plant. The new designed auto-feeding system will put the material into the reactor automatically. Thus will improve the efficient and make the reactor safer. With auto feeding, The indirect heat system will prevent the reactor from blast and will enlarge the area of heating.

- When we burn the reactor we will use wood,coal,or oil gas. the heat fuel is only used on start-up to heat the reactor, wnen the reactor can generate oil gas. our waste tire and plastics pyrolysis plant will be heated with its own oil gas. That means just little energy is required to heat the reacor.

- the oil gas will go into the condenser. The condenser is used to cool the oil gas into liquid. Inside the condenser there are 57 cooling pipes with diameter 48mm each inside the condenser,which means the cooling area of each condenser is 13 m2. Take the 10T capacity for example, there are 5 condensers ,so the total cooling area can reach 65 M2 Therefor the oil yield rate is guaranteed.Then there are two horizontal condensers for our 5th generation pyrolysis machine. its inner structure is similar with that of vertical condenser.however,the cooling area of one horizontal condenser can be equal to more than three vertical condensers. And also,the cooling way is longer than vertical condenser.In this way,there will be a better oil output.

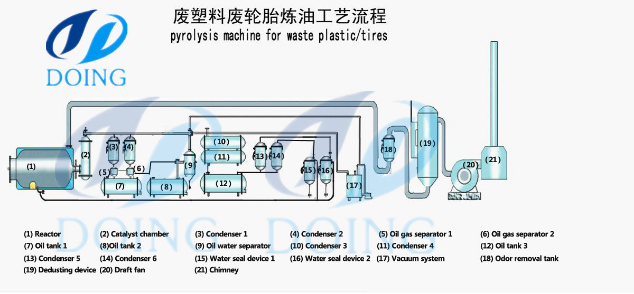

The waste tire and plastics pyrolysis plant working process

Waste tire and plastics pyrolysis plant working process

1. Feed raw material (waste tire、plastic) into reactor by full-automatic feeding machine. The reactor is supposed to be left 1/3 space for rotating more smoothly. Then make sure the door of feeding machine is closed.

2.Pyrolysis process: reactor will be gently heated by burning the fuel material (coal, wood, natural gas, LPG or tire oil generated from last batch). The oil gas will be released when the temperature reached 100℃(250-280℃ is the top output rate interval). Heavy oil gas separated by manifold is supposed to be liquefied and drop down into the heavy oil tank. The lighter gas will rise up to the oil condensers, be liquefied in to oil and stored in the oil tank. The incondensable gas though dusulphurization and dedust by hydroseal will be led to the furnace for recycling.

3..After all fuel oil is produced, the reactor should be cool down. Carbon black will be discharged automatically when the temperature falls down 40 degree. If the raw material is the whole tire, please take out steel wire form the reactor by hooks below 50 Celsius at least.

4.There possibly will be a little exhaust gas left, please must expel it after reaching emission standard.

5. Before starting next batch, make sure all the work has been done.

| Technical parameter of waste tire and plastics pyrolysis plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tire/plastic | Waste tire/plastic | Waste tire/plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste tire and plastics pyrolysis plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

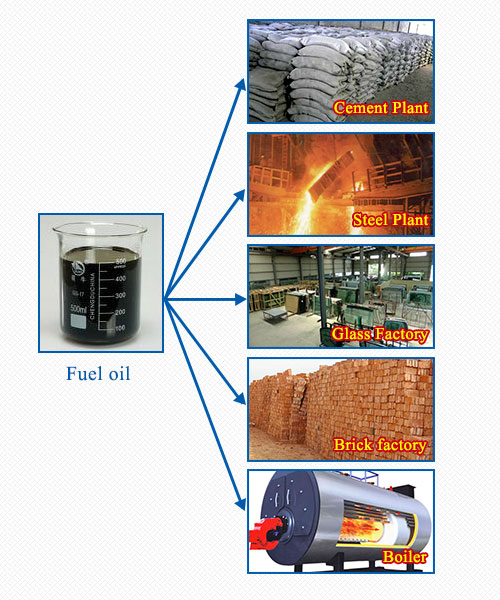

The waste tire and plastics pyrolysis plant final product application

Fuel Oil (45% to 52%)

The main application of oil products produced by our waste tire and plastics pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. Such as power plant factory,glass factory,cement factory,ceramic fatory.

Exhaust gas (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Steel Wire (12% to 15%)

The third product of waste tire and plastics pyrolysis plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

Carbon Black (30%)

The second product of waste tire and plastics pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. Carbon black can application to electric cable jacketing,black nylon bag,rubber additive

Request Information

Send your inquiry for further information