Waste rubber tire plastic recycling machines

Waste rubber tire plastic

Waste rubber tire plastic recycling machines

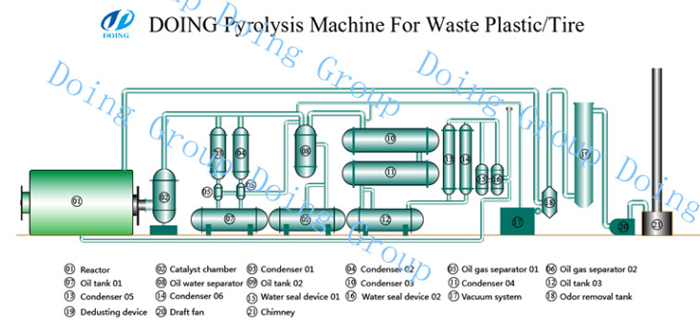

Waste rubber tire plastic recycling machines working process

Waste rubber tire plastic recycling machines

2.Pyrolysis process: reactor will be gently heated by burning the fuel material (coal, wood, natural gas, LPG or tire oil generated from last batch). The oil gas will be released when the temperature reached 100℃(250-280℃ is the top output rate interval). Heavy oil gas separated by manifold is supposed to be liquefied and drop down into the heavy oil tank. The lighter gas will rise up to the oil condensers, be liquefied in to oil and stored in the oil tank. The incondensable gas though dusulphurization and dedust by hydroseal will be led to the furnace for recycling.

Waste rubber tire plastic recycling machines advantage

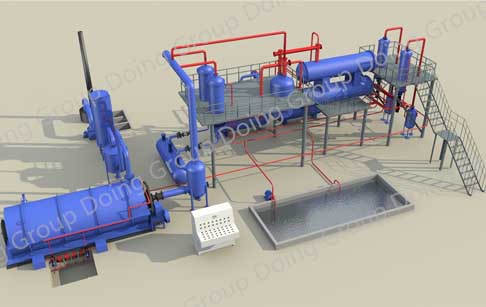

Waste rubber tire plastic recycling machines 3D picture

Environmentally: we have well dedusting system to dedust the dust. The off-gas the waste plant&tyre generated is recycled to heat the reactor so little energy is required to run the machine. The water used to cool the water is clear; the water is non-contact with the oil gas. So when one process is finished the water can be recycled.

Higher oil yield rate: we enlarge the cooling area of the condenser thus improving the oil yield rate. And we have special catalyst to improve the oil yield rate. With years’ experience and development we have our special technology to improve the oil yield rate.

Safer: All our products have the well-sealing system to prevent the gas from leaking to avoid blast. And we have the X-ray system to ensure the sealing to make the reactor safer. The vacuum system will prevent the oil gas going back to the reactor to cause exploration. what is more we have the anti-fire system to ensure safer.

Low cost: The pyrolysis plant is designed to use little energy. And the energy is only used in the start-up of the machine, once the machine is running; it does not need external energy. It just needs little fuel to start the machine.

| Technical parameter of waste rubber tire plastic recycling machines | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic/rubber/tire | Waste plastic/rubber/tire | Waste plastic/rubber/tire |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about waste rubber tire plastic recycling machines | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |

Waste rubber tire plastic recycling machines final product application

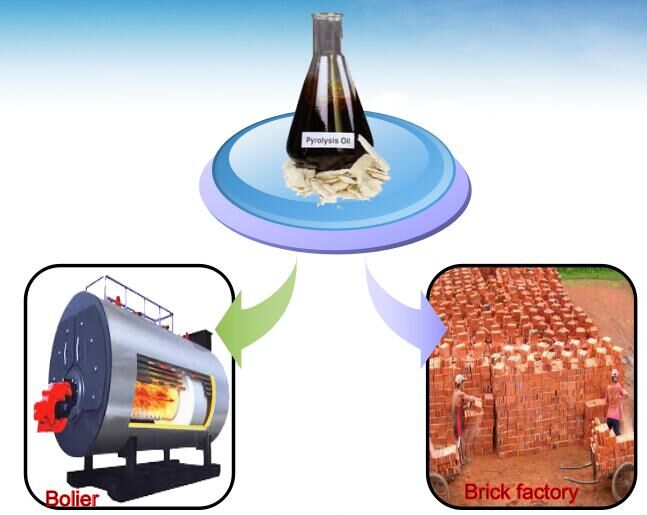

1.Crude oil (45%-50%): Oil from this machine can be used as industrial fuel for burning.

Fuel oil application

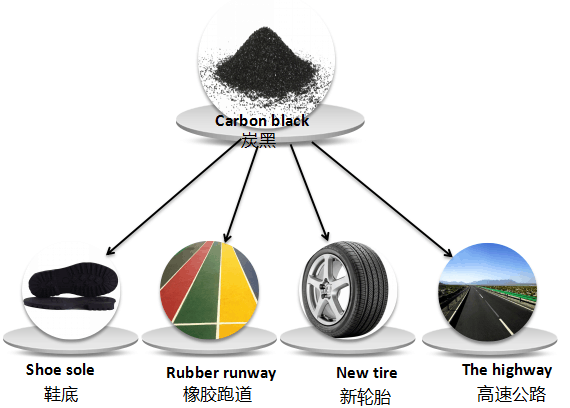

Carbon black application

4. Waste gas (5%): we have a special design could recycling it into fire furnace for burning.

Request Information

Send your inquiry for further information