Plastic pyrolysis plant project report

Waste plastic pyrolysis plant

Plastic pyrolysis plant can appliation to which raw material and oil yiled?

Waste plastic pyrolysis plant

1.General plastic (PET and polyster can't have a pyrolysis process)

2.Polyvinyl Chloride PVC (such as film, cable, floor, pipe plate, pipe, soles, toys, doors and windows, wire sheath, stationery, etc.) are difficult for pyrolysis.

3.Polythene PE (such as the thin film, diaphragm, film membrane, bottles, electrical appliances insulation, galvanic isolation materials, reticule, water pipes, oil tank, oil drum, drink bottle, calcium feeding-bottle, milk bottle, staple goods, necessity, etc.), the pure oil yield is about 95% 4.Polypropylene PP (such as the thin film, plastic pipe, plastic crokery, basin, barrel, furniture, woven bag, bottle cap, vehicle bumpers, etc.) the pure oil yield is about 90%

5.Polystyrene PS (such as the electric appliance, stationery, cup, food containers, casing of electric appliance, electric accessories, foam, toys, etc.) the pure oil yield is about 90%. PS (such as the electric appliance, stationery, cup, food containers, casing of electric appliance, electric accessories, foam, toys, etc.) the pure oil yield is about 90%.

Plastic pyrolysis plant working process

Waste plastic pyrolysis plant pyrolysis waste plastic to fuel oil and carbon black

Put raw material into reactor by full-automatic feeding machine. The reactor is supposed to be left 1/3 space for rotating more smoothly.

Then make sure the door of feeding machine is closed. Reactor will be gently heated by burning the fuel material (coal, wood, natural gas, LPG or tire oil generated from last batch).

The oil gas will be released when the temperature reached 100℃ (250-280℃ is the top output rate interval). Heavy oil gas separated by manifold is supposed to be liquefied and drop down into the heavy oil tank. The lighter gas will rise up to the oil condensers, be liquefied into oil and stored in the oil tank.

The incondensable gas through dusulphuration and dedusting by hydroseal will be led to the furnace for recycling. After all the above work has been done, cool down the reactor. Then the carbon black will be discharged automatically.

There possibly will be a little exhaust gas left, and you should not expel it until it has reached the emission standard. Before starting next batch, make sure all the work has been done.

| Technical parameter of Plastic pyrolysis plant project report | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about Plastic pyrolysis plant project report | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

Plastic pyrolysis plant final product 45% Pyrolysis oil (plastic oil)

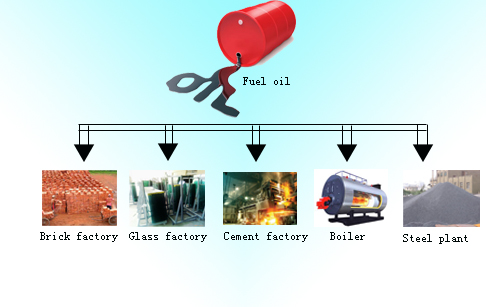

Plastic pyrolysis oil application

1. Add it into heavy oil generator to produce electricity.

2. Used as heating material.

3. Sell it into oil refining factory to further process it.

30% Carbon black

Carbon black application

2. Further process it into color master batch as basic material to make pipes, cable jacket…etc. Carbon black applicatio to Coal briquette factory, plastic factory, cable factory, etc.

Request Information

Send your inquiry for further information