Waste plastic to fuel equipment

Plastic to fuel

Waste plastic to fuel equpment

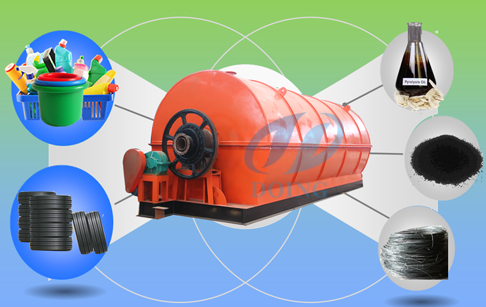

Pyrolysis system or plastic to fuel equipment is an industry for conversion of waste and plastic into usable products like Pyrolysis oil(Fuel oil) Carbon black Hydrocarbon gas Advantages of waste plastic to fuel equipment Purest quality of pyrolysis oil as finished product. Use of green technology to achieve environment friendly processes.

Automatic safely valve (pressure and temperature valve) use to improve safely, profitability & ease of operation. Industry is energy self-sufficient. No external fuel required for heating.

Benefits of waste plastic to fuel equipment

Plastic to fuel equipment

| Technical parameter of waste plastic to fuel equipment | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about Waste plastic to fuel equipment | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

Fuel oil application

1. Add it into heavy oil generator to produce electricity.

2. Used as heating material.

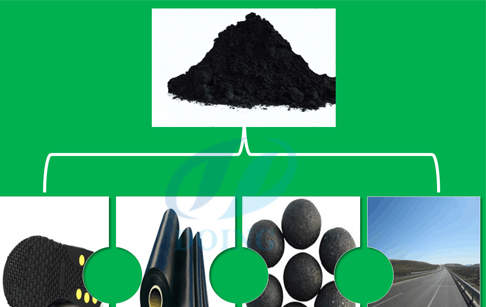

3. Sell it into oil refining factory to further process it. Sale market :Ceramic factory, glass factory, electric power factory, steel making factory, boiler factory…etc. 30% Carbon black 1. Make it into pellet or briquette for burning.

2. Further process it into color master batch as basic material to make pipes, cable jacket…etc.

Carbon black application

Request Information

Send your inquiry for further information