Pyrolysis plant design

The pyrolysis plant designed to turn waste plastic/tyre to fuel oil ,carbon black and carbon black. As a professional manufacturer of pyrolysis plant design, pyrolysis plants with the special design and good performance, which make them become more and more popular in the domestic and foreign markets.

1. Pyrolysis plant Reactor

It is the most important part of the pyrolysis plant, because it is the place where pyrolysis process takes place. Our reactor is made from Q345R steel, which can avoid it being burnt through, thus the service life of the reactor is longer. In addition, the reactor of batch and semi-continuous plastic waste pyrolysis machine is rotary, but for the fully continuous pyrolysis plant, the reactor is fixed. So the heating efficiency and working efficiency can be increased basing on the different capacity.

2. Condenser

Pyrolysis plant condenser

The new-type tubular condenser has the features of larger cooling area and better cooling effect. So it can improve the oil yield efficiency.

3. Dedusting System

Pyrolysis plant dedusting System

It mainly includes water sprayer, ceramic ring filter and washing chamber. It can remove the dust, dioxin and other component in the combustible gas, then the gas can be recycled to heat the reactor. Thus you can save a lot of energy cost. For the exhaust gas produced by burning the fuel, it can also be purified by the de-dusting system before emission.

4. Safety device

Pyrolsyis plant dedusting System

The pyrolysis plant is equipped with advanced safety devices, such as over temperature and pressure alarm system, auto pressure releasing system, protecting shell, fire fighting devices and so on, all of which can ensure the plant can work in a safe condition. At the same time, it can also protect the workers.

5. PLC Controlling System

It can achieve intelligent operation and avoid the mistakes caused by manual operation.

6. Various model

Our pyrolysis plants for sale are variuous in model. So the choice is flexible basing on the amount of the waste and the budget.

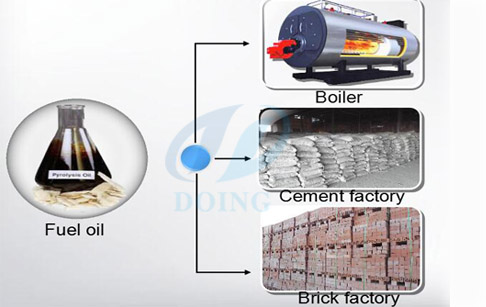

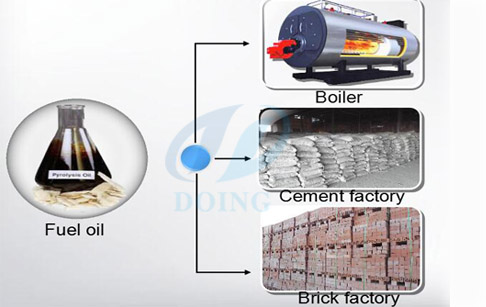

Fuel oil application

1. Pyrolysis plant Reactor

Pyrolysis plant Reactor

It is the most important part of the pyrolysis plant, because it is the place where pyrolysis process takes place. Our reactor is made from Q345R steel, which can avoid it being burnt through, thus the service life of the reactor is longer. In addition, the reactor of batch and semi-continuous plastic waste pyrolysis machine is rotary, but for the fully continuous pyrolysis plant, the reactor is fixed. So the heating efficiency and working efficiency can be increased basing on the different capacity.

2. Condenser

Pyrolysis plant condenser

3. Dedusting System

Pyrolysis plant dedusting System

It mainly includes water sprayer, ceramic ring filter and washing chamber. It can remove the dust, dioxin and other component in the combustible gas, then the gas can be recycled to heat the reactor. Thus you can save a lot of energy cost. For the exhaust gas produced by burning the fuel, it can also be purified by the de-dusting system before emission.

4. Safety device

Pyrolsyis plant dedusting System

The pyrolysis plant is equipped with advanced safety devices, such as over temperature and pressure alarm system, auto pressure releasing system, protecting shell, fire fighting devices and so on, all of which can ensure the plant can work in a safe condition. At the same time, it can also protect the workers.

5. PLC Controlling System

It can achieve intelligent operation and avoid the mistakes caused by manual operation.

6. Various model

Our pyrolysis plants for sale are variuous in model. So the choice is flexible basing on the amount of the waste and the budget.

| Technical parameter of pyrolysis plant design | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyres | Waste tyres | Waste tyres |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about pyrolysis plant design | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

Fuel oil application

| NO | Name | Percentage | Usage |

| 1 | Tyre fuel oil | 45% |

|

| 2 | Carbon black | 30% |

|

| 3 | Steel wire | 15% |

|

| 4 | Oil gas | 10% |

|

Request Information

Send your inquiry for further information