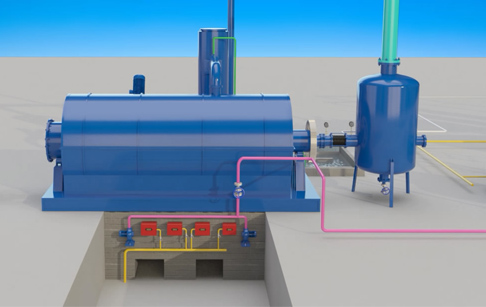

Tyre pyrolysis process plant

Waste tyre pyrolysis process plant

Tyre pyrolysis process plant reactor

Tyre pyrolysis process waste tyre to fuel oil

Pyrolysis of waste tyres is one of the most rea sonable alternatives by current environmental s tandards . This pyrolysis produces condensa ble hydrocarbons ( tar ) , gaseous components and a solid residue composed mostly of carbon ( char ) . Previous investigations have demonstrated that the liquid residue thus produced can be used directly as fuel oil and as a raw material in petrochemical processes . The gas can be used as fuel gas, while the carbon can be employed as carbon black in gasification processes and as a raw material for the production of activated carbon.

Waste tyre pyrolysis process plant pyrolysis process waste tyre to fuel oil and carbon black

1.Pretreatment

For the continuous type, its feeding hole is very small, so it needs a shredder machine to cut tyre into small pieces (about 30-50mm). While for the batch system, the tyre can be directly put into the reactor without being pretreated.

2. Feed raw materials

For the continuous type, the waste tires can be put into reactor by an auto-feeder. While for the batch type, this process is manual.

3. Tyre Pyrolysis

Heat the reactor by using fuel materials, such as coal, charcoal, fuel gas, wood etc. The reactor will be slowly heated, when the temperature reaches around 250℃, the oil gas will be produced.

4. Condensing

A part of oil gas will be processed by our technology and then goes to cooling system to form liquid oil. We adopt new-type condenser which can improve the oil yield efficiency and make the oil yield to the maximum.

5. Extra gas recycling

The gas which can not be liquefied under normal pressure will go back to combustion system. It can be used as fuel material to heat the reactor, which will save energy for the whole working process.

6. Discharge

In the process, there are also carbon black and steel wire produced. For the continuous type, the discharging of these two products are both automatic. While for the batch type, the discharging of steel wire is manual. When the temperature falls down to 40℃, workers can open the door and take the steel wire out.

When the whole working process has been finished, the reactor of the batch type must be cooled and then you can start another batch. After knowing their different working processes, you can choose the plant and system according to your actual need. For more requirement, we can also provide you with customized plants.

| Technical parameter of Tyre pyrolysis process plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste tyres | Waste tyres | Waste tyres |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about Tyre pyrolysis process plant | |||

| No. | Item | Consumption | |

| 1 | Coal(for choice) | 500kg/day | |

| 2 | Wood(for choice) | 800kg/day | |

| 3 | Natural gas(for choice) | 100-150kg/day | |

| 4 | Oil(for choice) | 300-350kg/day | |

| 5 | Electricity | 244kwh/day | |

| 6 | Water(recycled) | 60㎥ /month | |

| 7 | Total power | 19kw | |

| 8 | Land area | 35m*15m | |

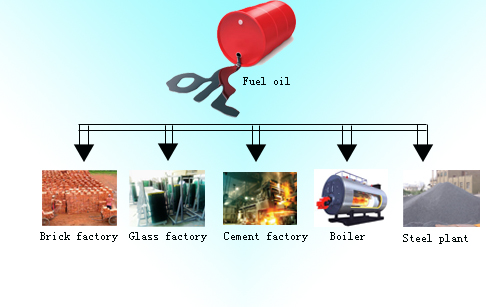

Waste tyre pyrolysis process plant final product application

Fuel Oil (40% to 45%)

Fuel oil application

The main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 40% to 45% of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks.

Carbon Black Powder (30% to 35%)

Carbon black application

Steel Wire Scrape ( 10% TO 15% )

The third product of waste tyre pyrolysis process plant is steel wire, the quantity of steel wire is about 10% to 15% according to tyre quality. Its very easy to sales steel wire scrape in local market.

Pyrolytic Gases ( About 10 % )

We get pyrolytic gases during process about 10% of waste tyre. The main component of this gases are methane ( CH4 ), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.

Request Information

Send your inquiry for further information