What is the final product of waste tyres pyrolysis plant ?

Industry News / Date:January 24, 2018

The final products of a waste tyre pyrolysis plant are mainly fuel oil, carbon black, and steel wire. Below we list the final products proportions and applications of waste tyre pyrolysis plant.

Waste tyre pyrolysis plant final products

Waste tyre pyrolysis plant final products

1. Fuel Oil (45% to 50%)

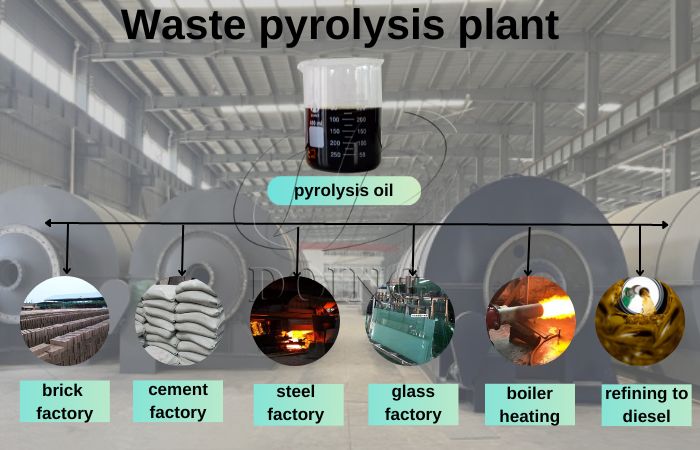

The main product obtained from our waste tyre pyrolysis plant application is fuel oil, which is widely used for industrial and commercial purposes, such as used as alternative heating fuel for various boilers and furnaces in steel factories, cement plants, brick making factories, heavy oil power/electricity generation, etc.

Tire pyrolysis oil(tpo) applications

Tire pyrolysis oil(tpo) applications

DOING waste tyre pyrolysis plant is equipped with a professional industrial-grade condenser and a patented negative pressure device to ensure a high oil yield during the pyrolysis process. The tyre pyrolysis oil(TPO) accounts for 45% to 50% of the total amount of recycled scrap tyres and can be further refined into non-standard diesel fuel for wide usages, such as used in diesel generators sets, trucks, ships, boats, heavy machinery, tractors, etc.

2. Carbon Black (30% to 35%)

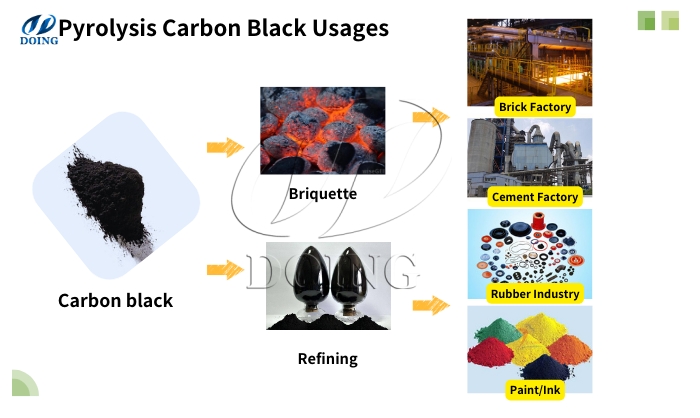

Carbon Black is the primary product recycled through pyrolysis technology. The amount of recycled carbon black varies between 30% to 35% (depending on the type of tyres) of the total amount of scrap tyres recycled in the system. Carbon black serves as a raw material or main ingredient in various industries. Its chemical structure strengthens materials, enhances their durability, and improves their coloring features.

Tyre pyrolysis carbon black applications

Tyre pyrolysis carbon black applications

The carbon black produced by the pyrolysis process (CBP) is more economical compared to carbon black derived primarily from petroleum. It is cost-efficient to use as an ingredient in industries such as:

(1)Rubber Industry: Carbon black is widely used as a reinforcing agent in the production of rubber products, including tires, belts, hoses, and seals. It improves the strength, abrasion resistance, and longevity of rubber materials.

(2)Plastic Industry: Carbon black is used as a pigment and UV stabilizer in the manufacturing of plastic products. It provides coloration, protection against sunlight, and increased durability to plastic items.

(3)Ink Industry: Carbon black is a key component in the production of printing inks. It enhances the color intensity, improves print quality, and ensures better adhesion to various printing surfaces.

(4)Coating Industry: Carbon black is utilized in the formulation of coatings and paints. It enhances the opacity, tinting strength, and UV resistance of coatings, making them suitable for various applications.

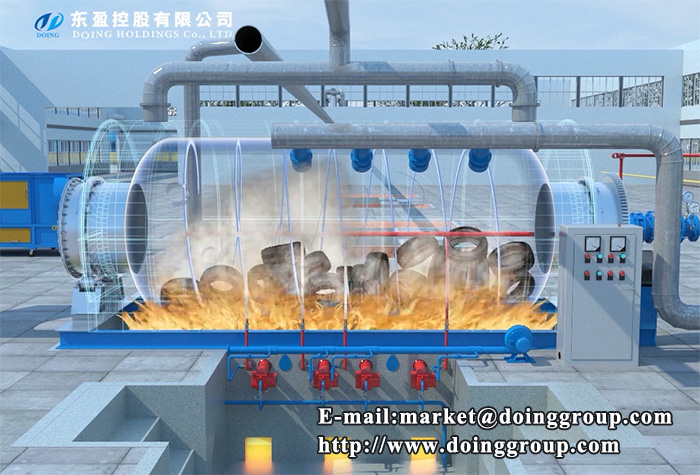

3. Syn-gas(about 10%)

The uncondesable gas produced in the waste tyre pyrolysis process can be directly used to heat the pyrolysis reactor to save investment cost.

Waste tyre pyrolysis plant heating way

Waste tyre pyrolysis plant heating way

4. Steel Wire (10% to 15%)

Tyres contain steel wires, accounting for approximately 10% to 15% of the total tyre wastage. After the completion of the pyrolysis recycling process, all the steel present in the tyre can be detached. The valuable steel wires are pressed and sold to steel and scrap dealers.

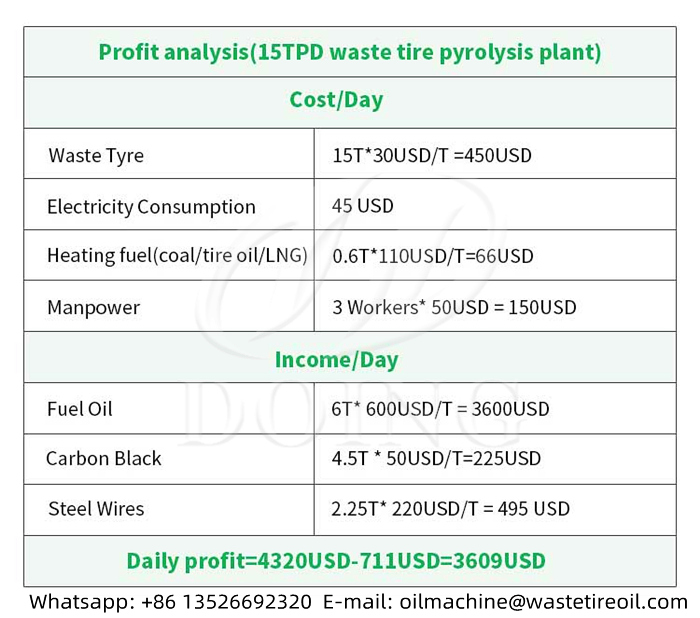

These four products derived from waste tyre pyrolysis plant have a wide range of applications, making this project a highly profitable and environmentally friendly investment opportunity. Here we also list the profit analysis of waste tyre pyrolysis plant for your reference.

Waste tyre pyrolysis plant profit analysis

Waste tyre pyrolysis plant profit analysis

If you want to engage in the waste tyre pyrolysis plant project and get advanced equipment to guarantee efficient and reliable production of fuel oil, carbon black, and steel wire from waste tyres. Welcome to send your inquiry to China leading pyrolysis plant manufacturer-Henan Doing Company for professional solutions!

Request Information

Send your inquiry for further information