What are the factors affecting chemical pyrolysis of plastic to fuel?

Industry News / Date:May 6, 2020

As we all know, almost all of plastic to fuel project customers want to improve oil rate of the plastic to fuel, and then increase the daily income. So we need first understand the factors affecting chemical pyrolysis of plastic to fuel, and then gradually improve. As a machinery manufacturer that has assisted more than 70 countries in installing waste plastic to fuel machine, Henan DOING summarized the following factors for your reference.

DOING waste plastic to fuel machine

DOING waste plastic to fuel machine

First, on the choice of waste plastic types

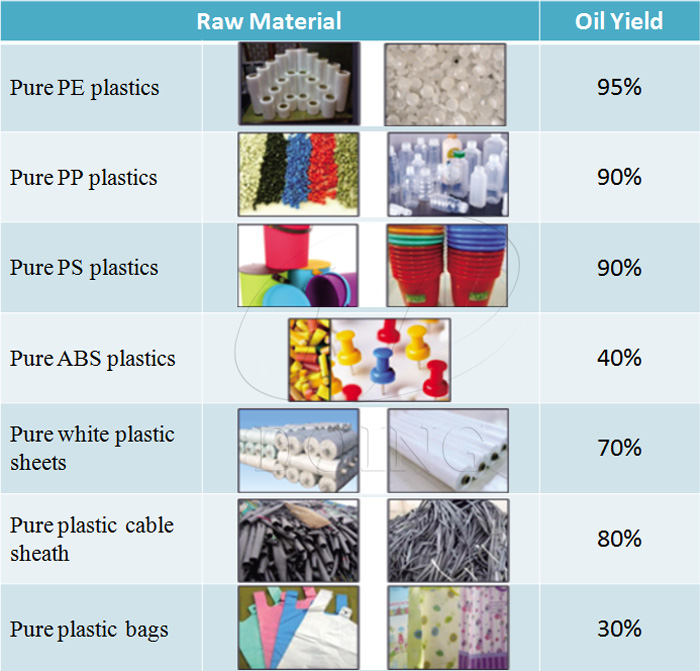

There are many types of plastics on the market, and not all plastics are suitable for pyrolysis into fuel oil. According to our research on waste plastic to fuel machine, it is concluded that general-purpose plastics PET polyesters and polyvinyl chloride PVC are not suitable for oil refining. Polyethylene PE, polypropylene PP, polystyrene PS, engineering plastics ABS, etc. are suitable for oil refining. And different kinds of plastics, oil yield is also different. So you can choose the high oil rate of plastic as raw material. Therefore, choosing plastics suitable for oil refining as the raw material for waste plastic to fuel machine is one of the factors that affect chemical pyrolysis of plastic to fuel.

Oil yield of different types of plastics

Oil yield of different types of plastics

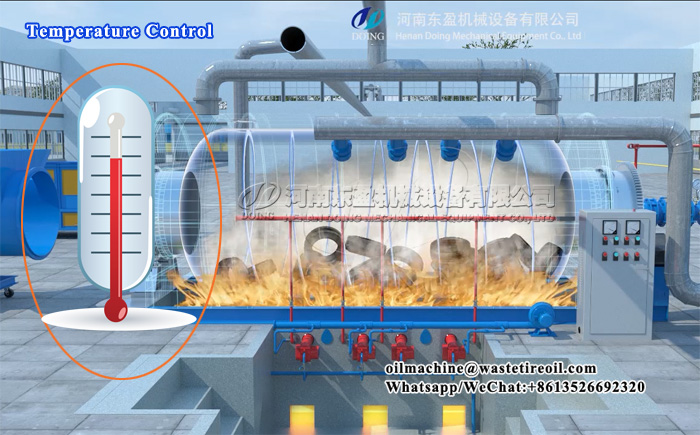

Second, temperature control when operating the waste plastic to fuel machine

During the operation of the waste plastic to fuel machine, it is necessary to operate the burner and heat the machine by observing the temperature of the thermometer to ensure that the waste plastic pyrolysis process is efficient and has a high oil yield. If the temperature control is not good, it may only be a small amount of oil produced. In response to this process, our company will send professional engineers to customers who purchase waste plastic to fuel machine to go to the customer's factory to debug and test the waste plastic to fuel machine. Workers can learn to operate the machine directly on site.

Temperature control when operating the waste plastic to fuel machine

Temperature control when operating the waste plastic to fuel machine

Third, ensuring a sealed environment during operation the waste plastic to fuel machine

The chemical pyrolysis of plastic to fuel is carried out under oxygen-free conditions, so the seals in the pyrolysis process are very heavy oil. If oxygen and plastic are mixed, the plastic will burn and cannot crack to produce oil and gas. So keep a sealed environment during operation the waste plastic to fuel machine is also a very important factor that affect chemical pyrolysis of plastic to fuel.

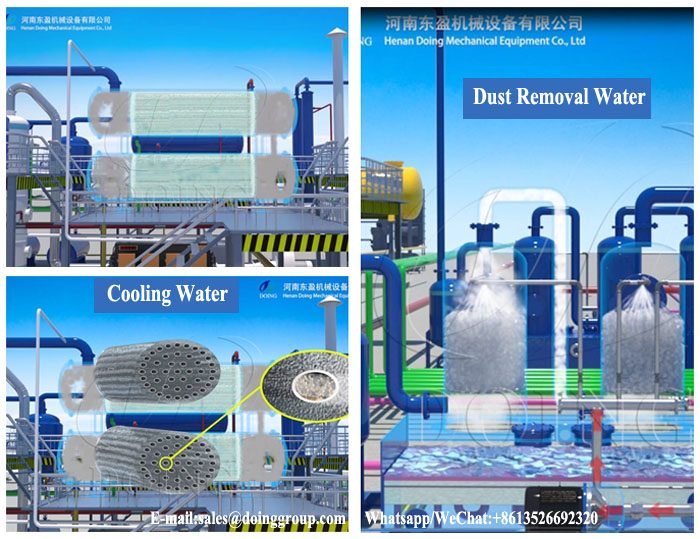

Finally, ensuring cooling effect in the chemical pyrolysis of plastic to fuel

It is is the final key step. Our company uses professional condensers and uses circulating water cooling to cool high-temperature oil gas into liquid fuel oil to ensure that the oil gas and water do not contact, and the cooling water is recycled to save energy and reduce emissions.

Waste plastic to fuel machine circulating water cooling system

Waste plastic to fuel machine circulating water cooling system

To sum up, choosing the type of waste plastic, controlling the temperature when the machine is running, ensuring a closed environment and ensuring the cooling effect are the main four important factors affecting chemical pyrolysis of waste plastic to fuel oil. So, when we do chemical pyrolysis of plastic to fuel, we can improve from these aspects.

If you are still worried about increasing the output rate of the waste plastic to fuel machine, or want to do the business of chemical pyrolysis of plastic to fuel, welcome to contact DOING company.

Request Information

Send your inquiry for further information