Can waste tyre pyrolysis plant deal with oilfield sludge?

Industry News / Date:May 16, 2020

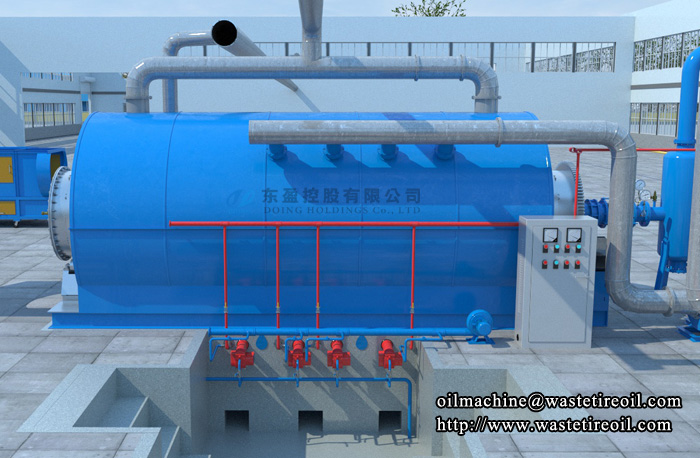

Waste tyre pyrolysis plant in the early stage is mainly used to treat waste tires, waste plastics, waste rubber, household waste and other raw materials. After years of technical improvement, DOING company has added multi-stage separator, static and static airtight system and other devices on the basis of the waste tyre pyrolysis plant. The improved new waste tyre pyrolysis plant can be used to deal with oilfield sludge. According to the characteristics of the oilfield sludge and the boiling point of water and hydrocarbon, the waste tyre pyrolysis plant can refine the oilfield sludge, so that the oilfield sludge can be recycled reasonably.

Waste tyre pyrolysis plant can deal with oilfield sludge

Waste tyre pyrolysis plant can deal with oilfield sludge

Principle of waste tyre pyrolysis plant dealing with oilfield sludge:

We know that oilfield sludge is formed by the mixing of crude oil with some impurities, and the crude oil itself is a mixture of various liquid hydrocarbons. Hydrocarbons can be decomposed into small and heavy molecules at high temperatures, then we can collect them according to the different characteristics of each component.

Oilfield sludge

Oilfield sludge

The specific working process of waste tyre pyrolysis plant dealing with oilfield sludge

Under the condition of no oxygen, the oilfield sludge is heated in the pyrolysis reactor. As the temperature increases, the hydrocarbon substances in the oilfield sludge absorb heat and undergo pyrolysis reaction to produce light components and liquid heavy oil. Heavy oil and impurities are collected together into liquid tank. The lightweight components including water vapor, the pyrolysis gas, light oil, etc., will pass through the condenser circulating water cooling system, in this process water vapor and light oil can be cooled into liquid. The remaining pyrolysis gas will be cooled through the oil channel condensation system and collected into product oil storage tank. The left small number of non-condensable gas will be used to heat pyrolysis reactor, which can reduce raw material costs.

Pyrolysis reactor

Pyrolysis reactor

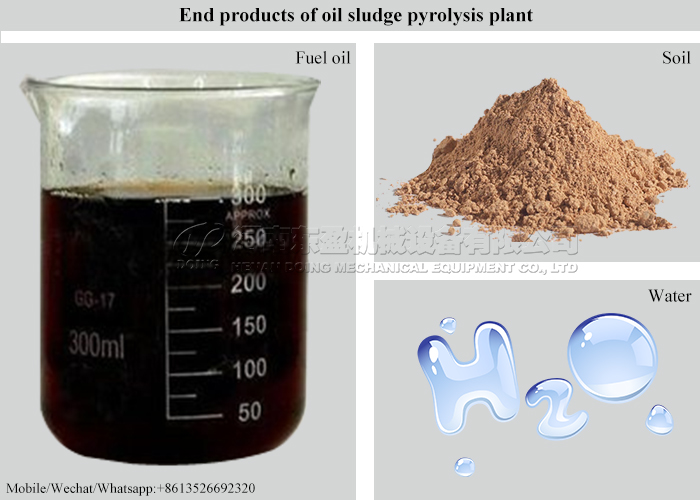

By using the pyrolysis technology of waste tyre pyrolysis plant, the oilfield sludge is well treated, and obtained fuel oil, soil, water and other high-yielding products. We also call it as oil sludge pyrolysis plant. With the use of pyrolysis plant, not only oilfield sludge can be recycled and reduced, but also no secondary pollution can be generated in the process of thermal cracking, and the waste emissions can be reasonably utilized. It can be seen that waste tyre pyrolysis plant improved can deal with oilfield sludge.

The final product from oilfield sludge by waste tyre pyrolysis plant

The final product from oilfield sludge by waste tyre pyrolysis plant

Henan DOING is a collection of production, research and development, sales and after sales in the integration of manufacturers, not only can provide the standard types of waste tyre pyrolysis plant, can also be customized according to your demand. Especial in the treatment of oilfield sludge, waste tyre, waste plastics, etc of any technical problems you are welcome to inquire.

Request Information

Send your inquiry for further information