How long does the tyre pyrolysis process take?

Waste Tire/Plastic Pyrolysis Plant / Date:July 20, 2023

It will take a different time to finish one batch for different tyre pyrolysis machines. Today I will take the common 100/500KG and 10/12TPD waste tyre pyrolysis machines as examples to discuss about how long the tyre pyrolysis process takes:

1. 100/500KG waste tyre pyrolysis machine

Because the 100/500KG waste tyre pyrolysis machine has relatively smaller processing capacity and easier configurations, they will take shorter time of the tyre pyrolysis process. For the 100KG waste tyre pyrolysis machine, the time consumption for one batch is about 3-4 hours, and for the 500KG waste tyre pyrolysis machine, the time consumption is about 7-8 hours.

DOING 100KG waste tyre pyrolysis machine for sale

DOING 100KG waste tyre pyrolysis machine for sale

2. 10/12TPD waste tyre pyrolysis machine

The 10/12TPD waste tyre pyrolysis machine takes about 22 hours for the tyre pyrolysis, mainly affected by the equipped configurations of the waste tyre pyrolysis machine:

1) Feeding: There are two ways to feed

(1) Feeding by manual, you need 3-4 workers for feeding, needs about 3 hours, suitable for the area whose manual cost is very low.

(2) Feeding by an auto-feeder, cooperated with a grab machine, just needs two workers. It takes about 1-1.5 hours to finish feeding, saving labor and feeding time.

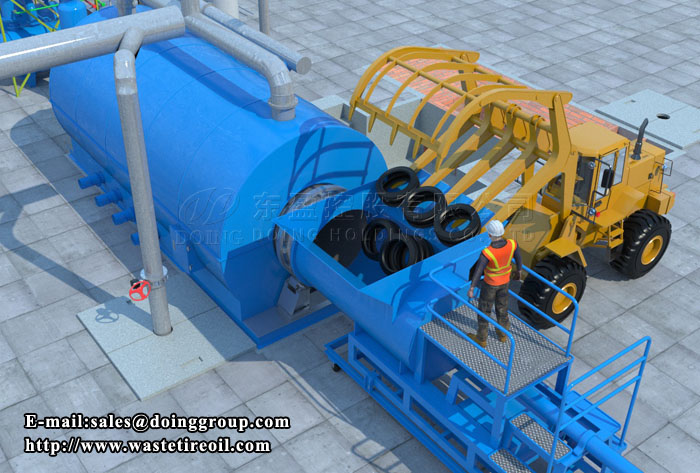

DOING Auto-feeder machine to enhance working efficiency

DOING Auto-feeder machine to enhance working efficiency

2) Heating Stage:

Use the pyrolysis oil and oil burner to heat the temperature to about 160 degrees, then the tail gas will be produced stably. After tail gas is produced, the machine will be mainly heated by the tails gas, maintain the temperature at about 280-320 degrees. This stage will take about 8-10 hours.

3) The cooling time of reactor:

(1) Vacuum device: Before discharging the carbon black, we need to open the vacuum device to pump the residual oil gas from the reactor to avoid safety accidents, which needs to take about 1 hour.

DOING patented safety device: Vacuum device

DOING patented safety device: Vacuum device

(2) Fast cooling system for reactor: The traditional design pyrolysis machine needs about 7 hours to cool, while DOING waste tyre pyrolysis machine adopts the new design and equipped the fast cooling system for reactor, which just needs about 4 hours.

4) Discharging carbon black:

After cooling, we need to discharge the carbon black. This process will take about 1.5 -2 hours.

In addition to the types and configurations of waste tyre pyrolysis machine, there are also other factors affecting the tyre pyrolysis time, such as weather condition, worker operation, tyre states, etc.

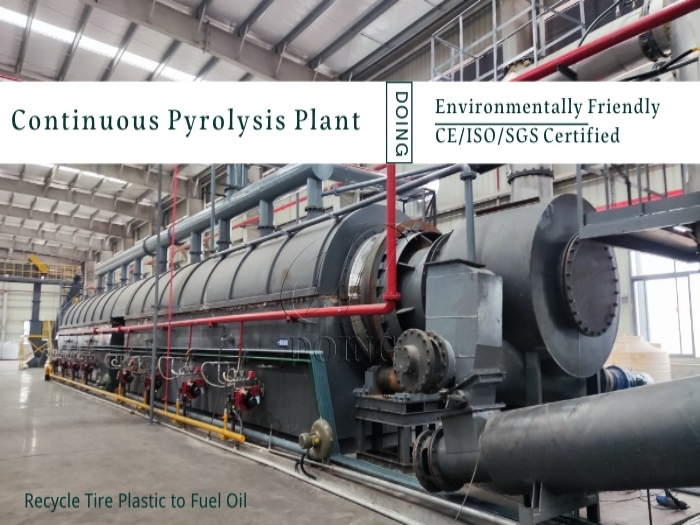

DOING continuous waste tyre pyrolysis machine for sale

DOING continuous waste tyre pyrolysis machine for sale

Henan DOING Company has researched waste tyre pyrolysis machines for over 13 years, we provide multiple types for you with various capacity. And DOING also researched the continuous waste tyre pyrolysis machine, which has higher working efficiency and bigger processing capacity and can work continuously for nearly two months. If you have abundant waste tyre to process, this type will be the best choice for you, which will help you enhance the working efficiency and generate more profits.

If you are interested in waste tyre pyrolysis, please feel free to contact us, our sales manager will share the more detailed information about various waste tyre pyrolysis machines.

Request Information

Send your inquiry for further information