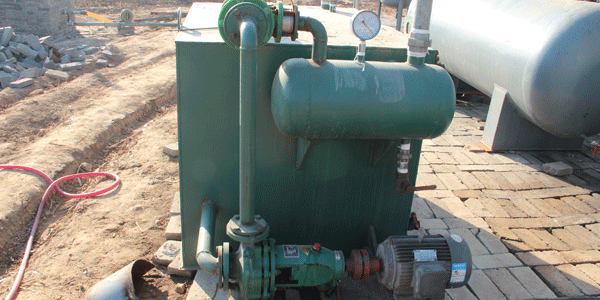

Vaccuum system of pyrolysis machine

When it comes to oil refining of waste plastic pyrolysis machine field or relevant industries, people will smell the danger in them. It takes much higher temperature than normal to heating the raw material until the available substance is pyrolyzed. Every step during the whole process is essential, especially the temperature and pressure regulation, because once they are not well operated and controlled, fire or even explosion will definitely visit. None of clients wants to come across disaster like that. Hence, Henan DOING Mechanical Equipment Co. Ltd. is forever focusing the safety issue in the technology. And vaccuum system was published as the times and clients require.

Vaccuum system of pyrolysis machine

Vaccuum system is responsible for controlling and keeping the main machine, in other words, the reactor running with high temperature yet under normal pressure, to be exact lower pressure. However, the reactor is not working alone to produce oil and other salable products, it is connected with hundreds of other components, including the oil pipe, oil-water-separator, and water cooling system. Therefore, the negative pressure has to be perfectly jointed with all other parts, and protects them during processing time.

It is specially designed by a mixture of air and other formula, creating vacuum inside to reduce the pressure provided by the main engine. When the fuel starts heating, main machine running, oil gas producing, and the temperature climbing, the pressure will naturally tend to increase immediately. Right at this moment the negative pressure created by vacuum runs rapidly to weaken the high pressure provided by the former part.

The seconds when negative pressures meet with high pressure, the whole processing line would calm down under a particularly safe circumstance. Besides, this device keeps working until the main machine cease, thus the entire refining process is well watched and protected. Fire or explosion will be killed before it grabs any chance to damage. Most clients would wisely choose this device when they are determined to order. And it is also our patented product, the most advanced technology until now in pyrolysis machine field.

Vaccuum system is one part of pyrolysis plant. The mainly function is keep pyrolysis plant in a safety running.

At long last, welcome to manufacturer of Henan DOING Mechanical Equipment Co. Ltd to know more details of this unique safety design, because the essence is not published before clients visit. Core details will only be released for those who are sincerely interested and prepared to explore with real action.

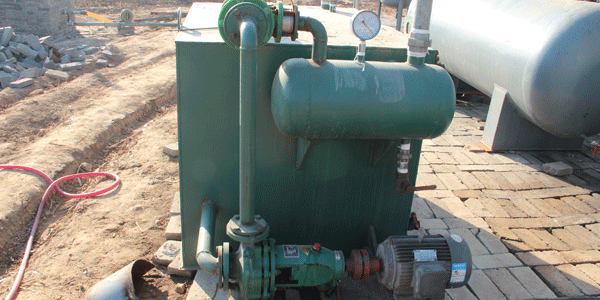

Vaccuum system of pyrolysis machine

It is specially designed by a mixture of air and other formula, creating vacuum inside to reduce the pressure provided by the main engine. When the fuel starts heating, main machine running, oil gas producing, and the temperature climbing, the pressure will naturally tend to increase immediately. Right at this moment the negative pressure created by vacuum runs rapidly to weaken the high pressure provided by the former part.

The seconds when negative pressures meet with high pressure, the whole processing line would calm down under a particularly safe circumstance. Besides, this device keeps working until the main machine cease, thus the entire refining process is well watched and protected. Fire or explosion will be killed before it grabs any chance to damage. Most clients would wisely choose this device when they are determined to order. And it is also our patented product, the most advanced technology until now in pyrolysis machine field.

Vaccuum system is one part of pyrolysis plant. The mainly function is keep pyrolysis plant in a safety running.

At long last, welcome to manufacturer of Henan DOING Mechanical Equipment Co. Ltd to know more details of this unique safety design, because the essence is not published before clients visit. Core details will only be released for those who are sincerely interested and prepared to explore with real action.

Request Information

Send your inquiry for further information