3 FAQs about Waste Tire pyrolysis equipment

Waste Tire/Plastic Pyrolysis Plant / Date:February 27, 2024

When starting a waste tire pyrolysis project and purchasing waste tire pyrolysis equipment, people are often most concerned about the oil yield, profit, safety and environmental protection of the pyrolysis equipment. Today, let DOING editor answer three common questions about waste tire pyrolysis equipment in detail.

1. What is the oil output percentage of tire pyrolysis equipment?

There are two points that determine the oil yield of waste tire pyrolysis equipment, one is raw materials, and the other is equipment design. Different raw materials have different oil production ratios. For example, scrap tires such as large truck tires, engineering tires, and small steel wire tires have a relatively high oil production rate, while bicycle tires, electric motorcycle tires, etc. have a lower oil production rate.

Oil Output percentage of different tires

Oil Output percentage of different tires

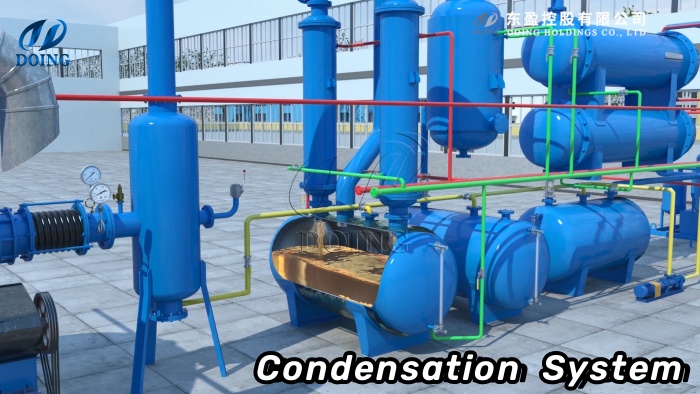

Next, from the pyrolysis equipment perspective, the different processes, technologies, and quality of different manufacturers of waste tire pyrolysis equipment will affect the oil yield. During the operation stage of pyrolysis equipment, whether the oil yield can be guaranteed mainly depends on the condensation system. The condensation system designed by DOING Waste Tire pyrolysis equipment Manufacturer has four condensation systems, including vertical condenser, oil-water separator, horizontal condenser and condensation tower, with a total cooling area of up to 100 square meters, which can stably maintain the efficiency and output percentage of waste tire pyrolysis oil.

Multi-stage oil condensation system of tyre pyrolysis equipment

Multi-stage oil condensation system of tyre pyrolysis equipment

2. What's the profitability of waste tire pyrolysis equipment?

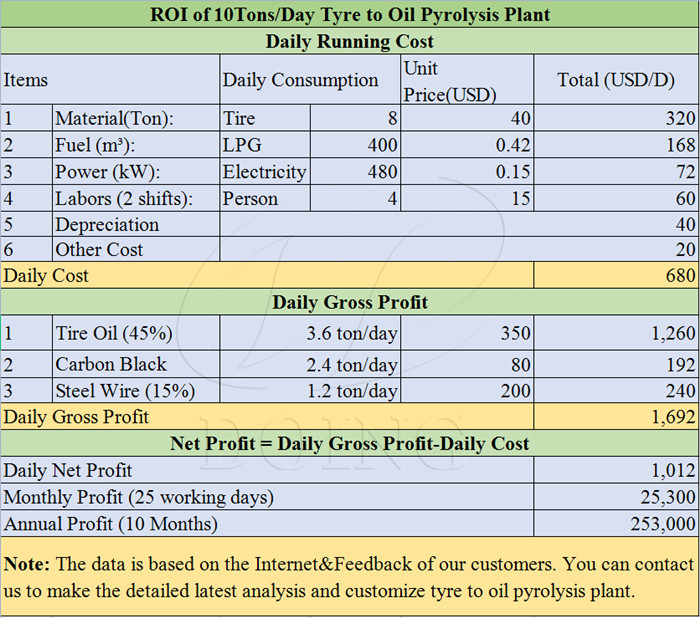

The profit generated by the waste tire pyrolysis project is naturally the most concerned issue among the frequently asked questions about waste tire pyrolysis equipment. In fact, the economic profits brought by the tire to oil pyrolysis production line are easy to calculate. The price of raw materials, product prices, labor, water and electricity consumption during operation are all open and transparent. If you choose DOING waste tire pyrolysis equipment, then DOING will issue you a feasible profit forecast.

Tire pyrolysis equipment profitability analysis

Tire pyrolysis equipment profitability analysis

However, the waste tire pyrolysis project profitability is greatly affected by market fluctuations. And different regions have different policies, so market research can be conducted in advance.

3. Is waste tire pyrolysis equipment safe and environmentally friendly?

The safety and environmental protection degree of waste tire pyrolysis equipment is the cornerstone of truly entering the waste tire pyrolysis industry, because some countries have strict control over the requirements or formalities for environmental protection of equipment.

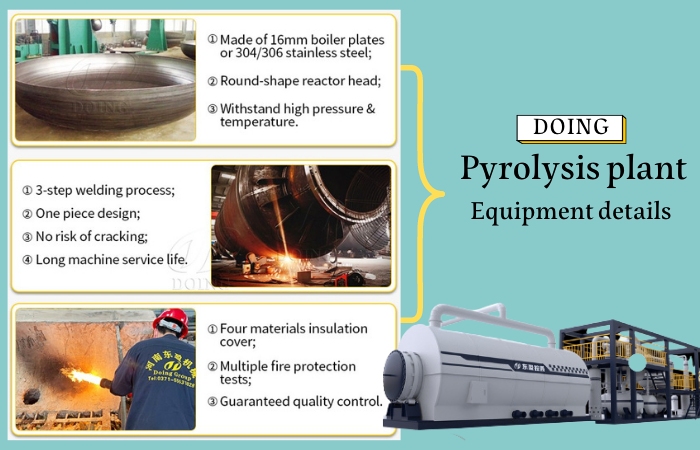

From a safety perspective, there are generally no problems with waste tire pyrolysis equipment produced by major manufacturers on the market today. Manufacturers will design layers of encrypted safety prevention systems to ensure the safety of waste tire pyrolysis equipment. When purchasing waste tire pyrolysis equipment, it is suggested to choose equipment with acceptable quality and professional steel or industrial plate materials, or you can conduct an on-site inspection of the factory.

DOING tyre pyrolysis equipment design details

DOING tyre pyrolysis equipment design details

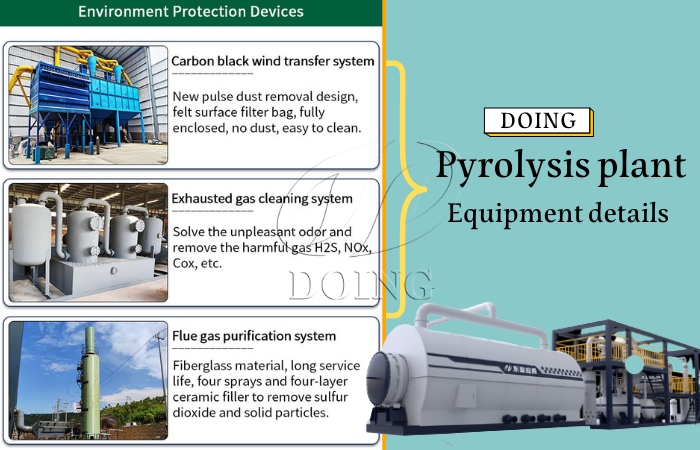

From the perspective of environmental protection of pyrolysis equipment, it mainly depends on the control of waste gas, waste water and solid residue by the tire pyrolysis equipment. DOING tire pyrolysis equipment adopts a circulating water cooling system, which basically produces no waste water. For the carbon black produced during the tire pyrolysis process, our machine is equipped with a relatively sealed conveying device that can collect the carbon black. And the fully continuous type tire pyrolysis equipment has an effective and fully sealed carbon black collection system to maintain the clearness of factory environment. As for waste gas, on the one hand, we purify and recycle the non-condensable combustible gas generated and use it to heat pyrolysis reactors to help customers save operating costs for tire pyrolysis equipment; on the other hand, for combustion exhaust gas, our machine has the environmental device of purification system and desulfurization tower, which ensures the compliance with emission standards.

DOING tyre pyrolysis equipment environmental devices

DOING tyre pyrolysis equipment environmental devices

More FAQs and machine information about DOING waste tire pyrolysis equipment, please follow the update of Henan Doing Company. Welcome to contact us for an inquiry!

Request Information

Send your inquiry for further information