What's the plastic to fuel pyrolysis process?

Waste Tire/Plastic Pyrolysis Plant / Date:December 12, 2023

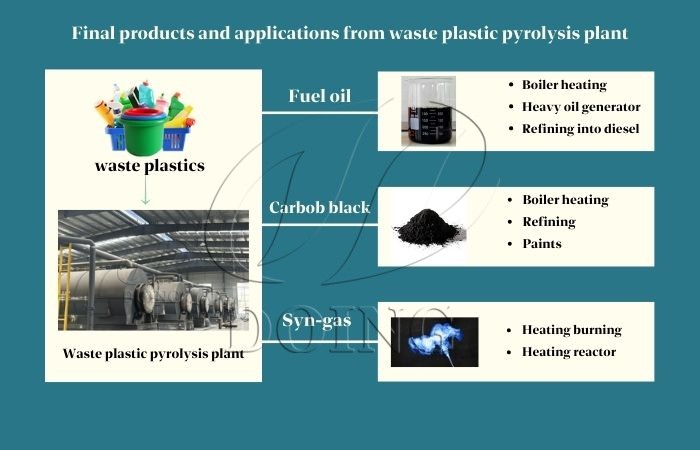

Pyrolysis plastic into fuel with pyrolysis machine is an environmentally friendly and economical waste plastic recycling way to reduce pollution. By plastic pyrolysis process, we can make fuel, carbon black and syn-gas, which can be used as renewable energy.

Plastic pyrolysis machine final products

Plastic pyrolysis machine final products

Let me introduce how waste plastic is pyrolyzed into fuel oil by pyrolysis machine.

The first step is feeding. If a grabbing machine is used in conjunction with an automatic feeding machine, the entire feeding process only requires two workers to operate, and the time is about 1.5 to 2 hours, which can fill a reactor with a daily processing capacity of 12 tons pyrolysis machine. If an automatic feeder is not used, the entire feeding process will take 2-3 workers 3-4 hours to complete.

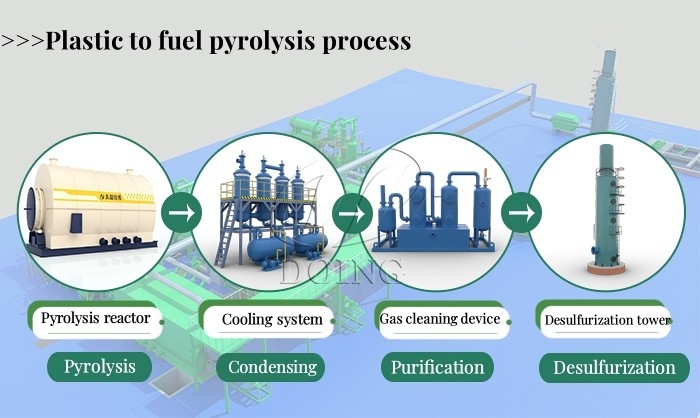

Plastic to fuel pyrolysis process

Plastic to fuel pyrolysis process

The second step is pyrolysis in the absence of oxygen. After the feeding is completed, the combustion burners need to be opened to heat the reaction kettle. In the first two hours, achieve a large amount of heat absorption under anaerobic conditions, which will evaporate the water in the waste plastic. Next, the temperature will gradually increase to 200 degrees. By controlling the burners to maintain the temperature between 230 and 260 degrees, it is the oil output stage, which needs to last for about four hours. Next is the constant temperature reaction stage, where the temperature will decrease and it needs to be controlled to gradually increase until the oil output decreases. Heat it over high heat to reduce the temperature to 150 degrees, ensuring that the fuel oil is fully extracted out.

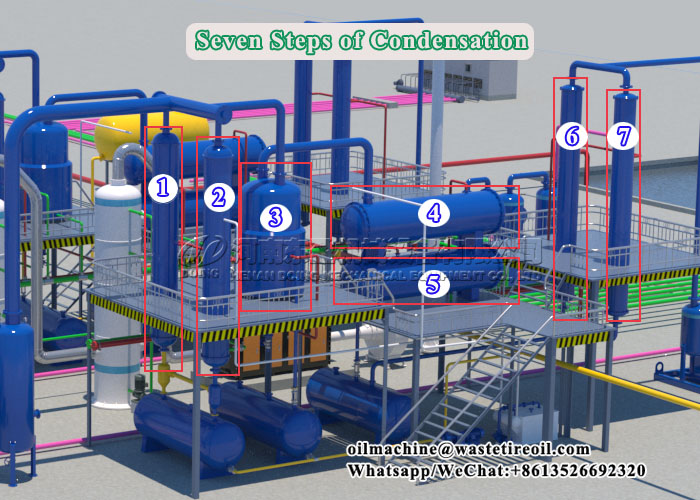

The third step is the condensation stage. The cooling system of DOING waste plastic pyrolysis machine adopts multiple-stage design. The cooling sequence from front to back is: two vertical tube condensers, one oil-water separator, two horizontal condensers, and two condensation towers. The first oil tank contains heavy oil that has been cooled down through vertical condensers, while the oil in the second and third oil tanks will be better. The two horizontal condensers have the largest cooling area and the best effect, allowing 80% -90% of the oil to be cooled down. The addition of two cooling towers once again ensures the issue of oil yield. All condensers use circulating cooling water, achieving zero discharge of wastewater.

Plastic to fuel pyrolysis machine condensation system

Plastic to fuel pyrolysis machine condensation system

The fourth step is the environmental control system. Firstly, the non-condensable gas is treated, and a deodorization system is used to remove hydrogen sulfide from the exhaust gas. A portion of the exhaust gas is returned to the pyrolysis reactor furnace for combustion to save heating fuel investment cost. In addition, it is necessary to carry out desulfurization and dust removal treatment on the flue gas generated by the heating reactor. We use a water mist dust collector to remove sulfur dioxide gas and solid particles from the flue gas, which not only achieves standard flue gas emissions but also extends the service life of the reactor.

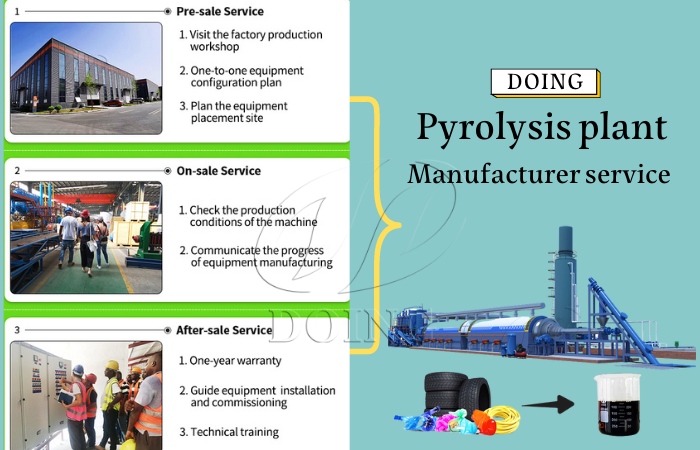

Plastic to fuel pyrolysis machine manufacturer service

Plastic to fuel pyrolysis machine manufacturer service

This is the entire pyrolysis process of converting waste plastic into fuel oil. If you are interested in engaging in waste plastic to fuel oil pyrolysis business, please feel free to contact Henan Doing Company, a leading pyrolysis machine manufacturer and supplier in China. From solution customization to plastic pyrolysis machine installation, we can be your professional consultants and offer all-around technical services.

Request Information

Send your inquiry for further information