Is your waste tyre pyrolysis plant safe?

Waste Tire/Plastic Pyrolysis Plant / Date:March 25, 2020

Safety always comes the first, our waste tyre pyrolysis plant is designed with special system to ensure the equipment safety.

1. We have the laboratory for testing the raw material, every time after we buy the steel from steel market, we will test at our laboratory, like the impact and tension strength. You know for this pyrolysis machine, reactor directly decide the service life of the whole machine, so is it very important of the quality of reactor.

DOING raw materials testing laboratory

DOING raw materials testing laboratory

2. We have 2 pressure valves, one in front of reactor and another behind the reactor, and one alarming. We set a number on the pressure gage, like 0.3-0.4mpa, once the pressure of the system reach this number, alarming will ring, if there is no one besides, pressure valve will open automatically.

The pressure gage

The pressure gage

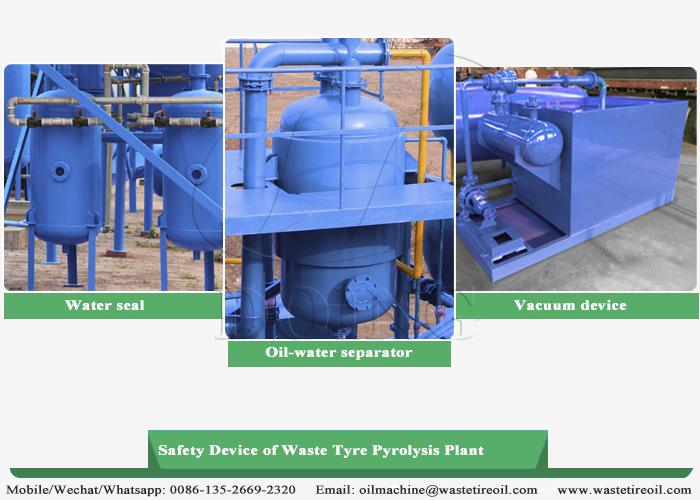

3. Oil-water device. Gas pipe is under the surface of water, because the pressure of water, the oil gas cannot go back to reactor, which can prevent the gas reflux to the reactor and avoid blast.

4. Water seal device is same with oil-water device.

5. Vacuum system. vacuum system is the unique device of our waste tyre pyroysis plant, which can ensure the whole plant operate under a negative pressure, and escape the hazard of high pressure in the inner system.

Three important safety device of waste tyre pyrolysis plant

Three important safety device of waste tyre pyrolysis plant

6. X-ray test. Just now testing the material is the first step, after welding them two times(one by welder, another by welding machine), we will use the X-ray test for testing welding crack line. If there is little leak, we will do again, you know it is very dangerous if there is any little leak during the welding, inside is oil gas, outside is fire, so test the welding is also very important.

These are some of safety device adopted in waste tyre pyrolysis plant. If you want to buy high safety waste tyre pyroysis plant, welcome to contact us.

Request Information

Send your inquiry for further information