Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What are oil sludge pyrolysis products and how to get them?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What are oil sludge pyrolysis products and how to get them?

What are oil sludge pyrolysis products and how to get them?

Waste Tire/Plastic Pyrolysis Plant / Date:December 29, 2020

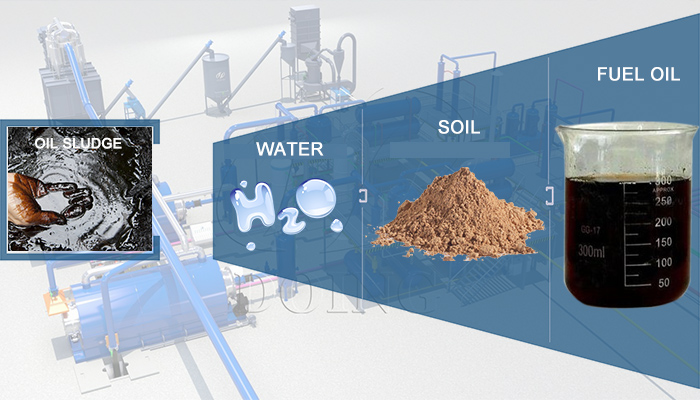

Oil sludge pyrolysis products include fuel oil, solids and water. The fuel oil is of high quality and can be used as fuel directly or refined into diesel for more uses. The solid waste accounts for a large proportion and it is mainly used to make construction materials.

Oil sludge pyrolysis products

Oil sludge pyrolysis products

How to get the oil sludge pyrolysis products? It's simple. Our oil sludge pyrolysis plant is specially made for this purpose.

Oil sludge pyrolysis plant

Oil sludge pyrolysis plant

Firstly, feed the oily sludge into pyrolysis reactor. If the oily sludge is liquid, pack it in ton bags at first while solid oily sludge can be fed directly.

Secondly, heat the reactor using fuel. When the temperature rises to 100℃, the water in the oily sludge begins to evaporate, and about 2 to 3 hours later the water is completely evaporated. At 200℃, the oil sludge begins to crack, releasing sulfides and nitrogen oxides. The oil gas is produced at this stage. Then when the temperature reaches 300℃, the particulate matter in the sludge begins to produce, which is solid waste.

Thirdly, cool oil gas into fuel oil. The oil gas is arranged to pass through cooling system where the temperature is so low that the oil gas will be turned into liquid fuel oil.

At last, collect the fuel oil and clean up pollutants. The fuel oil is collected in a tank temporarily. In the above process, there are four main pollutants produced: waste gas, waste water, noise and solid waste. In order for them not to pollute the environment, they must be treated before discharged. DOING oil sludge pyrolysis plant has a complete environmental protection configuration, so as to meet the environmental standards. If you have a interest in the oil sludge pyrolysis plant, welcome contact us.

Request Information

Send your inquiry for further information