Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>Which auxiliary equipment is needed to start tyre pyrolysis plant?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>Which auxiliary equipment is needed to start tyre pyrolysis plant?

Which auxiliary equipment is needed to start tyre pyrolysis plant?

Waste Tire/Plastic Pyrolysis Plant / Date:January 13, 2020

In general, our waste tyre pyrolysis plant can handle waste tyre directly and does not require any other auxiliary equipment to complete the entire tire pyrolysis process, but if you want to process more tyres per day or want to get better quality steel wire, you need the equipments as below.

1. If you want to handle more tires per batch

Tires have big space between each other. It is hard to feed enough quantity waste tires into the reactor without cutting the tires. For example, for a 10-ton daily tyre pyrolysis plant, you can feed 7~8 tones of waste tyres in the reactor at most without any cutting of the waste tires, because the space between each tire is very large, although our automatic feeder has 60 tones of hydraulic pressure, it cannot completely eliminate the space between the tires. So we can use some pre-treating equipment to reduce the space. You can buy a tire cutting machine, cut off the ring circle of the tires, and then prepare a tire tripling machine to put the tires together. Of course, you can also choose a tire crusher to directly shred the tire, but the crushing machine is more expensive and bigger consumption for power. Therefore, the first solution can not only reduce the cost, but also greatly reduce the space between the tires and increase the throughput.

Waste tire was fed into the reactor after its ring circle being cut off

Waste tire was fed into the reactor after its ring circle being cut off

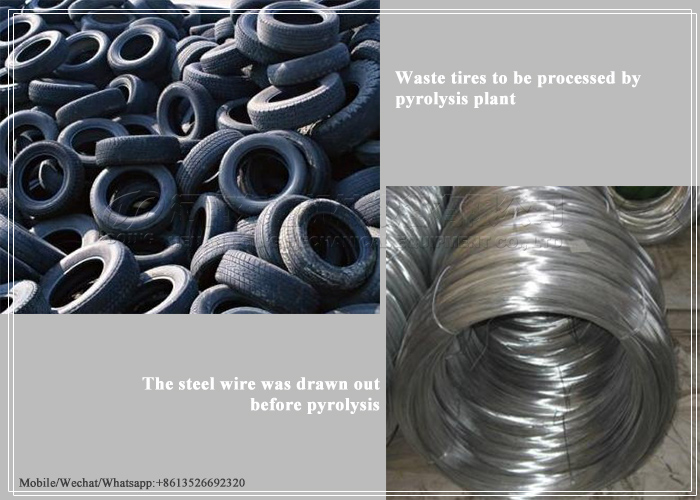

2. If you want to get higher quality wire

As we all know, the original steel wire in the tire is a good raw material and can be sold directly to the steel factory with a high price. However, the quality of the steel wire after high temperature will be greatly reduced, and the sale price will be much lower than the original. If you want a better quality steel wire, you can pull out the steel wire before feeding. So you can buy a hydraulic tire wire drawing machine that can pull 90% of the wire out from the tire and then pyrolysis it. So you will get double profit from the steel wire this way.

The steel wire was pulled out before pyrolysis for better quality

The steel wire was pulled out before pyrolysis for better quality

Henan DING Company has been engaged in the tire pyrolysis equipment manufacturing for more than 10 years and has many valuable experiences. If you want to get more ideas about the tyre pyrolysis plant, you are welcome to leave a message on our website any time.

Request Information

Send your inquiry for further information