Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What shall we concern when we select pyrolysis plant suppliers?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What shall we concern when we select pyrolysis plant suppliers?

What shall we concern when we select pyrolysis plant suppliers?

Waste Tire/Plastic Pyrolysis Plant / Date:January 19, 2021

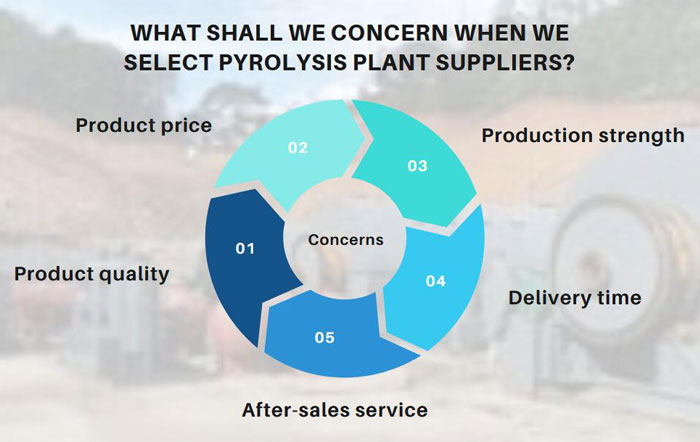

With the popularity of the pyrolysis industry, more and more manufacturers and intermediaries begin to become suppliers of pyrolysis plants. A good supplier needs to have many advantages in terms of product quality, product price, production strength, delivery time, and after-sales service. And these advantages will help you to start a successful pyrolysis business. Therefore, this article explains what we shall concern when we select pyrolysis plant suppliers.

What shall we concern when we select pyrolysis plant suppliers?

What shall we concern when we select pyrolysis plant suppliers?

1. Product quality

Product quality is the basis of whether you can successfully enter the pyrolysis industry or not. It determines the quality of the final product, as well as the whole operation efficiency. It has a great impact on the market competitiveness of your company. Therefore, quality is an important factor in selecting the right supplier. For example, DOING pyrolysis reactor adopts Q245 boiler plate, which can handle about 1800 batches of raw materials. The condenser adopts four-step high-efficiency condensation design, which greatly improves the oil output rate and reduces the waste of raw materials. And the flue gas treatment system can ensure the discharge gas meets the environmental protection standard.

2. Product price

Low price means that manufacturers can reduce production and operation costs, which plays an important role in improving competitiveness and increasing profits. However, the cheapest pyrolysis plant is not necessarily the most suitable. Under the same conditions, usually the manufacturer's price is lower than the middleman's price, because the middleman will receive part of the rebate between the manufacturer and the consumer. DOING is a world-leading manufacturer with more than 10 years of experience in the production of pyrolysis plants, which ensures that you buy cost-effective machines.

3. Production strength

Three types of Doing pyrolysis plant

Three types of Doing pyrolysis plant

In the pyrolysis industry, different consumers have different needs and in order to meet the needs of consumers, suppliers need to be able to offer a variety of capacities and configurations of pyrolysis plants. Doing group has developed different models, capacities and configurations, including small pyrolysis plants from 500kg-1ton, batch pyrolysis plants from 3ton-20ton and continuous pyrolysis plants from 10ton-60ton to meet customers’ standards and local requirements.

4. Delivery time

The ability to deliver pyrolysis plant on time and at the agreed upon location will directly affect the continuity of the customers’ production activities. The stock of DOING pyrolysis plant and the transportation companies we have cooperated with for many years can guarantee on-time delivery so that customers can put into the production of pyrolysis oil as soon as possible.

5. After-sales service

Good after-sales service is the guarantee that the pyrolysis plant can run smoothly. A good supplier not only provides high quality pyrolysis plants, but also provides experienced installation engineers to guide the installation and training of operators. Doing group can provide on-site installation service, video guidance, online guidance, installation and operation manuals and lifetime technical support.

It is indeed not easy to select the best supplier from many manufacturers. You can consider these five aspects referred to above before purchasing a pyrolysis plant, which will hopefully help you make a better decision. If you have any questions, please feel free to contact us.

Request Information

Send your inquiry for further information