Waste plastic pyrolysis plant process ?

Waste Tire/Plastic Pyrolysis Plant / Date:July 19, 2017

Waste plastic pyrolysis plant process

As the demand for alternate sources of fuel becomes more pronounced, it is quite natural for the world to look at the various options available. Plastic is a commonly used product and each day the world over, millions of tons of plastic waste is generated. The environmentalists and the administrators are certainly struggling at avenues which could help in safe disposal of this waste or recycle it for better use.

Waste plastic pyrolysis plant process is a technology available whereby one could go in for suitable pyrolysis plant and how it could help in coming out with an alternate source of energy which is clean, sustainable and affordable. Therefore if you are one of those on the lookout for suitable waste plastic pyrolysis plant process for sale you certainly have reasons to find the next few lines interesting and informative.

.

Which raw material can be application to waste plastic pyrolysis plant process?

Waste plastic pyrolysis plant process is a technology available whereby one could go in for suitable pyrolysis plant and how it could help in coming out with an alternate source of energy which is clean, sustainable and affordable. Therefore if you are one of those on the lookout for suitable waste plastic pyrolysis plant process for sale you certainly have reasons to find the next few lines interesting and informative.

.

Which raw material can be application to waste plastic pyrolysis plant process?

Waste plastic pyrolysis plant process raw material

1.General plastic

(PET and polyster can’t have a pyrolysis process)

2.Polyvinyl Chloride

PVC (such as film, cable, floor, pipe plate, pipe, soles, toys, doors and windows, wire sheath, stationery, etc.) are difficult for pyrolysis.

3.Polythene

PE (such as the thin film, diaphragm, film membrane, bottles, electrical appliances insulation, galvanic isolation materials, reticule, water pipes, oil tank, oil drum, drink bottle, calcium feeding-bottle, milk bottle, staple goods, necessity, etc.), the pure oil yield is about 95%

4.Polypropylene PP (such as the thin film, plastic pipe, plastic crokery, basin, barrel, furniture, woven bag, bottle cap, vehicle bumpers, etc.) the pure oil yield is about 90%

5.Polystyrene

PS (such as the electric appliance, stationery, cup, food containers, casing of electric appliance, electric accessories, foam, toys, etc.) the pure oil yield is about 90%.

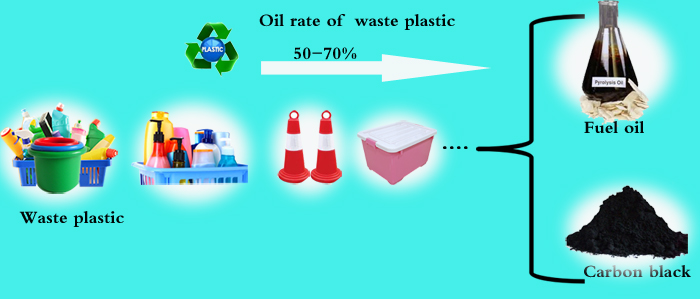

Waste plastic pyrolysis plant process waste plastic to fuel oil and carbon black

Waste plastic pyrolysis plant process waste plastic to fuel oil and carbon black

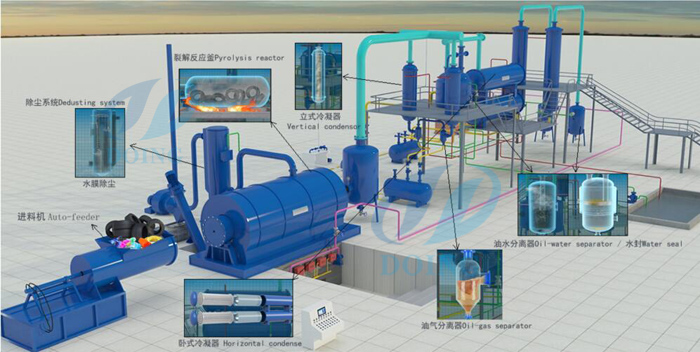

2. The liquid oil will be cooled by condenser from oil gas and then collected by oil tank. Third, the exhaust gas which can not be cooled in normal pressure will be recycled to heat the reactor. In this way, you can not only saving energy, but also protecting environment.

3. Smoke produced by plastic waste recycling plant processing the plastics can achieve national emission standard through dual desulfurization and dusting removal device.

4. After you get oil from plastic waste recycling plant process, the temperature will be low, at this time, carbon black will be discharged automatically.

Last, when the temperature falls to 100 degree Celsius,After all these steps, you can start another batch.

Request Information

Send your inquiry for further information