Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What are the differences between continuous pyrolysis plant and batch pyrolysis plant?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>What are the differences between continuous pyrolysis plant and batch pyrolysis plant?

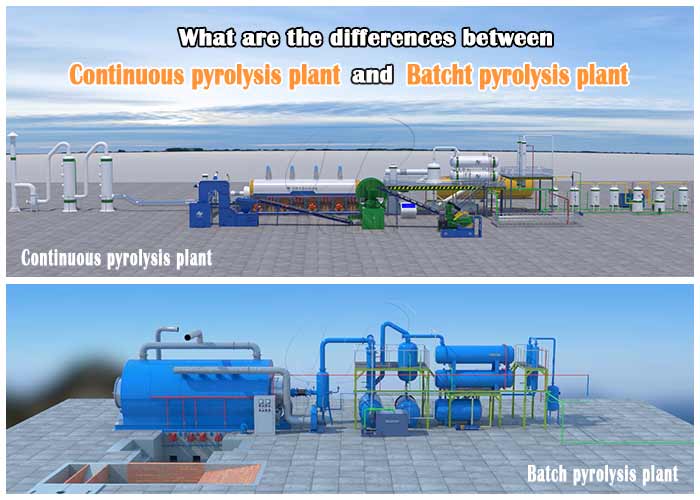

What are the differences between continuous pyrolysis plant and batch pyrolysis plant?

Waste Tire/Plastic Pyrolysis Plant / Date:May 14, 2021

As the progress of science and technology, automated, high oil yield and labor-saving pyrolysis plants are increasingly popular. Therefore, we have started to upgrade on the basis of our batch pyrolysis plant. And after several years of research, we have developed fully continuous pyrolysis plant with high efficiency, high performance and high automation. So far, our continuous pyrolysis plants have already accessed the international market and received incredible feedback. Now we are going to see the main differences between continuous pyrolysis plant and batch pyrolysis plant.

What are the differences between continuous pyrolysis plant and batch pyrolysis plant?

What are the differences between continuous pyrolysis plant and batch pyrolysis plant?

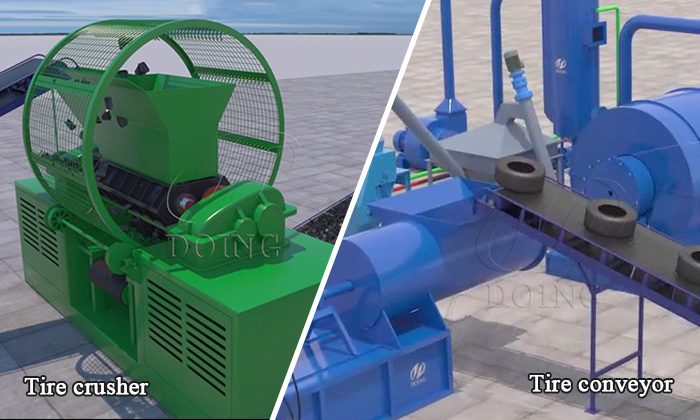

1. The difference of raw material processing method

Tire crusher vs tire conveyor

Tire crusher vs tire conveyor

Batch pyrolysis plant: You can put the whole tires into the reactor directly without any pretreatment.

Continuous pyrolysis plant: Because the feeding process of continuous pyrolysis plant is continuous and closed, in order to ensure that the feeding process is efficient you need to use the tire crusher to crush the tires into powder.

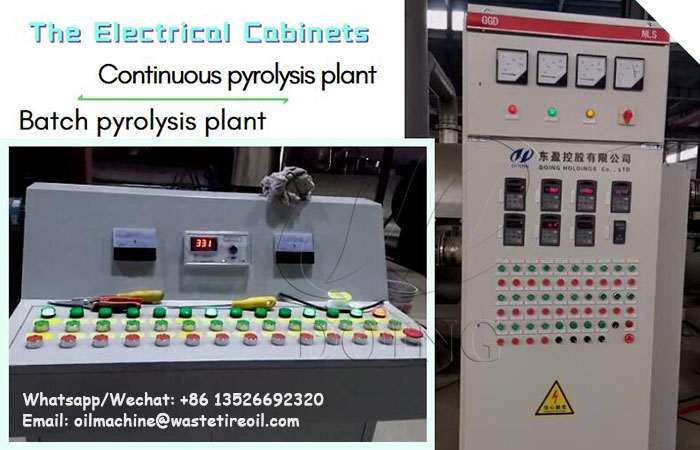

2. The difference of automation degree

Electrical cabinet of of continuous pyrolysis plant and batch pyrolysis plant

Electrical cabinet of of continuous pyrolysis plant and batch pyrolysis plant

Batch pyrolysis plant: Batch pyrolysis plant works in batch mode and requires about 4 workers. It feeds and discharges slag about once a day, completing the entire process before moving on to the next batch.

Continuous pyrolysis plant: Continuous pyrolysis plant works in uninterrupted mode, and the continuous feeding and discharging system is controlled by PLC system, which is fully automatic and requires almost no manual intervention.

3. The difference of slag discharge plant

Slag discharge equipment of continuous pyrolysis plant and batch pyrolysis plant

Slag discharge equipment of continuous pyrolysis plant and batch pyrolysis plant

Batch pyrolysis plant: Batch pyrolysis plant is a one-time slag discharge, and all tires must be fully pyrolyzed before carbon black is discharged. And the carbon black will be cooled to 50 degree Celsius in the reactor before discharge, so only a carbon black elevator is needed to collect the carbon black.

Continuous pyrolysis plant: Continuous pyrolysis plant is continuous and uninterrupted slag discharge, that is discharging carbon black in the process of pyrolysis. In order to keep the discharge temperature below 60 degrees Celsius, a three-stage slag discharge system is used.

4. The difference of motor

Batch pyrolysis plant: Batch pyrolysis plant adopts ordinary motor because the operation of batch pyrolysis plant will be interrupted in the middle to collaborate with manual labors.

Continuous pyrolysis plant: Continuous pyrolysis plant can run continuously and uninterruptedly for more than 30 days, so it adopts explosion-proof motor.

These are the main differences between continuous pyrolysis plant and batch pyrolysis plant. Even though continuous pyrolysis plant has long running time, high efficiency and high automation, and saves manpower, it is more expensive. So if you have enough money and consider the long-term benefits, you can choose continuous pyrolysis plant, if you want to save investment cost and optimize the operation step by step, you can choose batch pyrolysis plant. If you still have any questions, please feel free to contact us, our professional project manager will customize the right solution for you according to your situation.

Request Information

Send your inquiry for further information