Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>How safe and environment friendly is continuous waste tire pyrolysis plant?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>How safe and environment friendly is continuous waste tire pyrolysis plant?

How safe and environment friendly is continuous waste tire pyrolysis plant?

Waste Tire/Plastic Pyrolysis Plant / Date:May 14, 2021

Continuous waste tire pyrolysis plant is one kind of new type waste tire recycle equipment from Doing Company. It adopts PLC controller, an automatic control system. More importantly, compared with Batch type waste tire pyrolysis plant, it employs continuous feeding and discharging system, which can work 24 hours a day without stopping. That is how continuous waste tire pyrolysis plant improves the efficiency of the factory and decreases manpower cost.

Doing continuous waste tire pyrolysis plant 3D image

Doing continuous waste tire pyrolysis plant 3D image

As increasing popularity of continuous waste tire pyrolysis plant in the market, its safety problems and environment problems attract many attentions from customers. Today, we will show you more details about these two aspects.

✔ Safety

That’s very important for a factory to run smoothly. Here are some configurations Doing continuous waste tire pyrolysis plant use to ensure safety.

1.High quality pyrolysis reactor: Adopting 18mm boiler steel plate, curved compression head design, which can withstand high temperature and high pressure.

Pyrolysis reactor

Pyrolysis reactor

2.Security devices: There are pressure gauge, safety valve and alarm interlock devices on our continuous waste tire pyrolysis plant. When the pressure exceeds the set, safe valve will automatically open to release pressure and alarm to remind staff of trouble clearing.

3.Other devices: Water seal device for preventing syngas backflow; vacuum device for providing negative pressure to drain residual oil and gas ensuring safety and no odor.

✔ Environmental Protection

With the increasing awareness of environmental protection and policy requirements, people are also taking environmental protection into account. Primarily, converting waste tires into fuel oil is an environmental act to reduce the pollution of waste tires. And, we also have other systems to make sure the whole process of continuous waste tire pyrolysis plant is environmentally friendly.

Environmental protection devices

Environmental protection devices

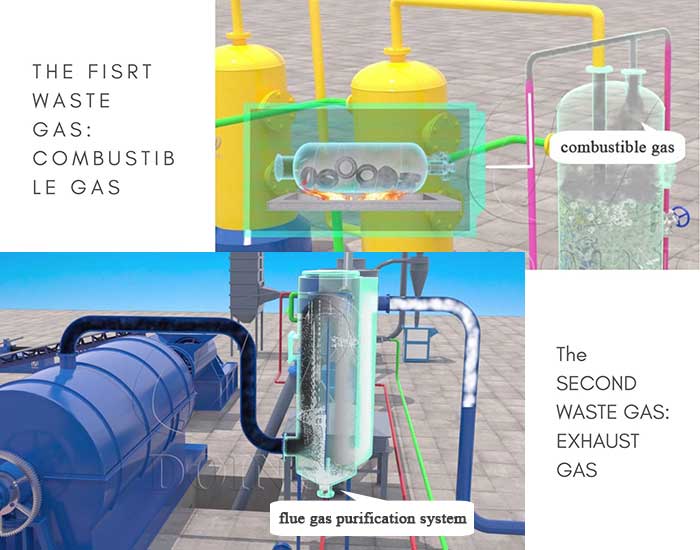

1.Combustible gas recycling system: The combustible gas after condensing system will be cleaned by tail gas purification system then recycled to furnace for heating pyrolysis reactor, which is no secondary pollution and save fuel.

2.Water circulating system: The entire condensing system employs water circulating system, no waste water discharged.

3.Desulfurization & purification tower: The flue gas generated by fuel combustion is purified by desulfurization & purification tower, which can remove dust and sulfur compounds and meet the emission standards of air pollution.

To sum up, you must now have a better understanding of the safety and environmental protection of Doing fully continuous waste tire pyrolysis plant. If you are interested in it, please contact us freely.

Request Information

Send your inquiry for further information