Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>How to improve the oil yield of waste plastic pyrolysis plant?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>How to improve the oil yield of waste plastic pyrolysis plant?

How to improve the oil yield of waste plastic pyrolysis plant?

Waste Tire/Plastic Pyrolysis Plant / Date:May 14, 2021

The waste plastic pyrolysis plant can convert waste plastic into fuel oil and carbon black by pyrolysis technology, and the customer can get a good profit from the products. Undoubtedly, the higher the oil yield is, the higher the profit the customer gets. So how to improve the oil yield of waste plastic pyrolysis plant?

How to improve the oil yield of waste plastic pyrolysis plant?

How to improve the oil yield of waste plastic pyrolysis plant?

Based on years of experience in the industry and feedback from customers, we have summarized four factors that affect the oil yield of waste plastic pyrolysis plant. They are the selection of raw materials, the pretreatment of raw materials, the condensing system of waste plastic pyrolysis plant and the skillful operation of workers. Let's see the details below.

1.The selection of raw materials

Various waste plastic

Various waste plastic

The oil yield of waste plastic pyrolysis plant is related to the type and purity of waste plastic. With different types of waste plastics, the oil yield varies, and even some of them cannot be pyrolyzed, such as PVC and PET. As for purity of waste plastic, usually the oil yield of pure waste plastic is higher than that of waste plastic with more impurities, for example, the oil yield of pure PE plastic has reached 95%, and the oil yield of pure PP plastic has reached 90%. Therefore, we should pay attention to the selection of raw materials, so as to further improve the oil yield of waste plastic pyrolysis plant.

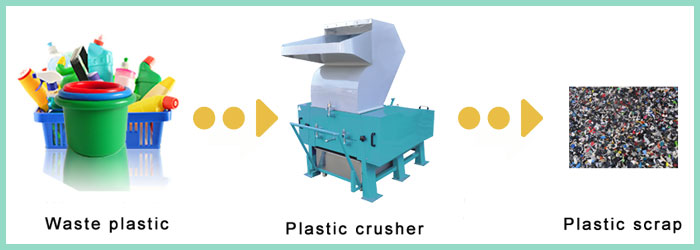

2.The pretreatment of raw materials

Plastic crusher

Plastic crusher

If you want to pyrolyze waste plastic more fully, you can pretreat the waste plastic before putting it into the pyrolysis reactor. Dry the waste plastic containing moisture, or use a plastic crusher to crush the plastic into fine particles, both of which can improve the oil yield.

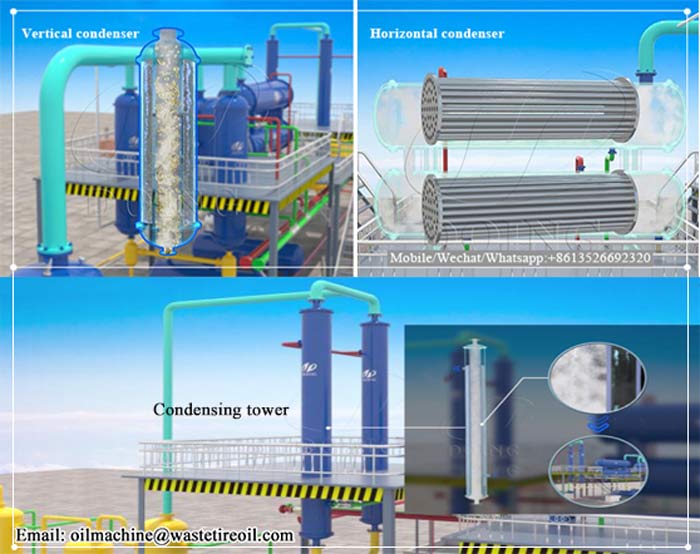

3.The condensing system of waste plastic pyrolysis plant

Condensing system

Condensing system

The oil gas produced in the pyrolysis reactor is mainly cooled into pyrolysis oil through the condensing system, so the design of the condensing system is very important. The most direct way to know the condensing effect of the condensing system is to look at the size of the cooling area. Doing waste plastic pyrolysis plant adopts the three-stage condensing system design of horizontal condenser, vertical condenser and condensing tower, which greatly increases the contact area of oil and water in the condensing system, thus improving the oil yield of the waste plastic pyrolysis plant.

4.The skillful operation of workers

Doing engineers provide instructional training to workers

Doing engineers provide instructional training to workers

If workers can skillfully operate the waste plastic pyrolysis plant, then the oil yield will be greatly improved. It is especially worth noting that if the workers are not skilled in operation and do not control the temperature well, the oil yield will be seriously affected. If the temperature is too low, the oil gas cannot be produced, and if the temperature is too high, the tail gas content in the oil gas will reach a certain peak, causing waste and also leading to a low oil yield. Doing Group has experienced engineers who can guide the training of waste plastic pyrolysis plant project, so that the operators can master the waste plastic pyrolysis process.

Now you know how to improve the oil yield of waste plastic pyrolysis plant. So, do you want to invest in waste plastic pyrolysis plant project? If you have this in mind, welcome to contact us.

Request Information

Send your inquiry for further information