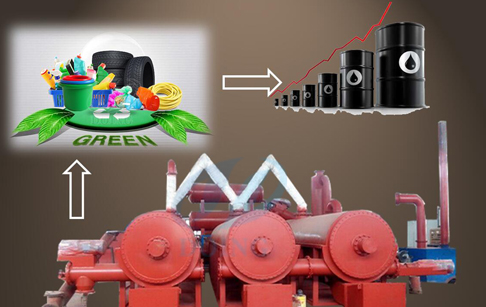

How does continuous pyrolysis tire to fuel?

Waste Tire/Plastic Pyrolysis Plant / Date:March 1, 2018

Renewable energy sources and various waste-to-energy initiatives are being explored globally; however, most of these initiatives are inefficient and environmentally unfriendly. This continues to put a lot of pressure on emerging countries to find cost-effective use of sustainable alternative fuels in order to reduce dependency on fossil-derived fuels.

Henan Doing produced continous pyrolysis tire to fuel oil adopts one advanced technology called pyrolysis or distillation, which takes advantage of high temperature and heat the tire oil to working temperature by using fuel oil, gas, coal etc.

Continuous pyrolysis tire to fuel machine

a.Waste tire pretreatment before feeding it into our continuous pyrolysis tire to fuel machine

As the photo shows, the ring cutter, tire strip cutter and black cutter work together to firstly remove the tire bead and cut the left tire into rubber blocks, and then use steel wire separator to separate the steel wire out of the tire bead. The rubber blocks and the bead after steel wire separating will be used as raw material for our continuous waste tyre pyrolysis plant. The steel wire got from the tyre bead can be packaged and sold directly.

b.Heating in advance to make the temperature of the continuous pyrolysis plant reactor rise up to about 300℃,fuel can be oil or gas, the heating is indirect heating by hot air produced by burners.

c.Turn on the auto-feeder, small tyre pieces loaded into reactor and pyrolysis begins; when reach certain temperature the gas oil is generated from the waste tire.

d.Oil gas generated and condensed into fuel oil to be stored, sync gas recycled and used as fuel during operation; at the same time, carbon black and steel wires in short also discharged from the auto-discharge system. The steel metal and carbon black separated automatically and stored.

Henan Doing produced continous pyrolysis tire to fuel oil adopts one advanced technology called pyrolysis or distillation, which takes advantage of high temperature and heat the tire oil to working temperature by using fuel oil, gas, coal etc.

Continuous pyrolysis tire to fuel machine

a.Waste tire pretreatment before feeding it into our continuous pyrolysis tire to fuel machine

As the photo shows, the ring cutter, tire strip cutter and black cutter work together to firstly remove the tire bead and cut the left tire into rubber blocks, and then use steel wire separator to separate the steel wire out of the tire bead. The rubber blocks and the bead after steel wire separating will be used as raw material for our continuous waste tyre pyrolysis plant. The steel wire got from the tyre bead can be packaged and sold directly.

b.Heating in advance to make the temperature of the continuous pyrolysis plant reactor rise up to about 300℃,fuel can be oil or gas, the heating is indirect heating by hot air produced by burners.

c.Turn on the auto-feeder, small tyre pieces loaded into reactor and pyrolysis begins; when reach certain temperature the gas oil is generated from the waste tire.

d.Oil gas generated and condensed into fuel oil to be stored, sync gas recycled and used as fuel during operation; at the same time, carbon black and steel wires in short also discharged from the auto-discharge system. The steel metal and carbon black separated automatically and stored.

Request Information

Send your inquiry for further information