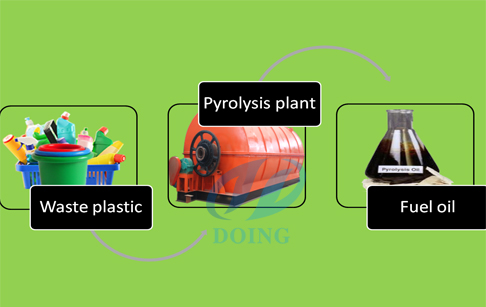

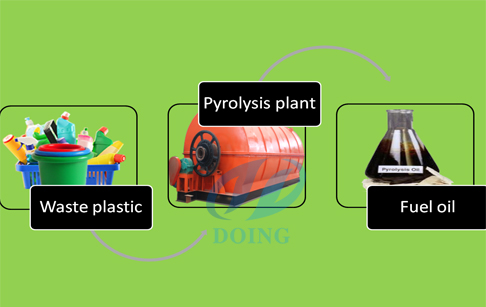

Plastic pyrolysis process plant

Plastic pyrolysis process can pyrolysis waste plastic to plastic pyrolysis oil and carbon black. it is clear that the waste plastic is able to give the liquid products which are with the same values of physical parameters as gasoline or kerosene fuels.

Plastic pyrolysis process plant pyrolysis waste plastic to fuel oil and carbon black

Process of pyrolysis is a thermochemical process conducted at high temperatures and usually in presence of catalysts. Different type of catalysts, natural and syntheti c, can be used for conversion of organic wastes into valuable fuels. The aim of this work is conversion of waste polyolefin mixture and production of liquid fuel using mixture of Al 2 O 3 and SiO 2 as a catalyst. Waste mixture was pyrolyzed at temperature rang e 400 - 550 o C and obtained products were liquid fuel, gas and minor solid residue. Under the optimized reaction conditions, the condensed liquid fraction is much larger than the gaseous fraction. Different amounts of catalyst and polyolefin mixture as a feed stock were used. According to the obtained results, the retention time and the percent of SiO 2 in the catalyst mixture have predominant effect on the amount of liquid product. Decreasing the quantity of SiO 2 in the catalyst mixture increased the yield of l iquid product. The physical properties of obtained liquid products were characterized and according to the measured values, liquid fuel belongs to light fraction of diesel fuel.

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>How is the definition of plastic pyrolysis process ?

Home > FAQ > Waste Tire/Plastic Pyrolysis Plant>How is the definition of plastic pyrolysis process ?