Applications of Pyrolysis Technology Introductory Video

Pyrolysis Plant Video / Date:January 6, 2026

Welcome to our video explanation of pyrolysis technology! The topic of this video is What is pyrolysis technology? What are the applications of pyrolysis technology? Below is a detailed overview of the key content covered in the video:

First, what is pyrolysis technology? As introduced in the video, it’s a a thermal decomposition process that breaks down organic materials into smaller molecular components in the absence of oxygen. This endothermic reaction typically occurs at high temperatures (300–900°C, depending on the feedstock and desired products).

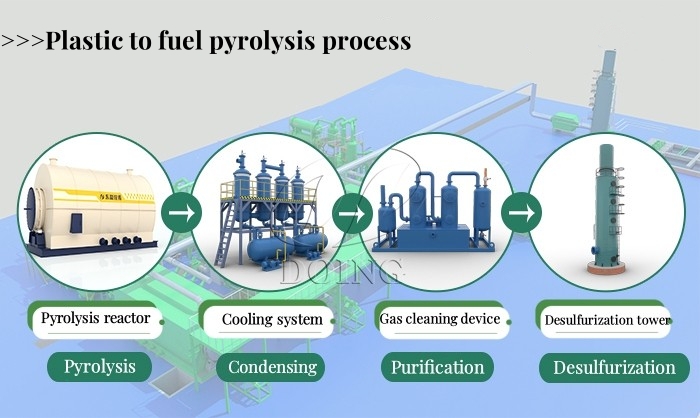

In the video, we also showcase the core structure of standard pyrolysis equipment consists of four core components: a feeding system, a heating furnace, a cooling system, and a tail gas purification system.

Waste to fuel pyrolysis process

Waste to fuel pyrolysis process

The video clearly demonstrates how pyrolysis works: It occurs when organic materials are placed in the pyrolysis reactor and heated by the pyrolysis furnace, pyrolysis decompose. This is due to the high heat, which causes chemical bonds to break, the organic material is broken down into gases, liquids which are fuels and some solid residues. Because of the value fuels, gases and solid residues, pyrolysis technology has significant uses in many areas. Our video focuses on three core applications of pyrolysis technology, all of which are critical for sustainable development:

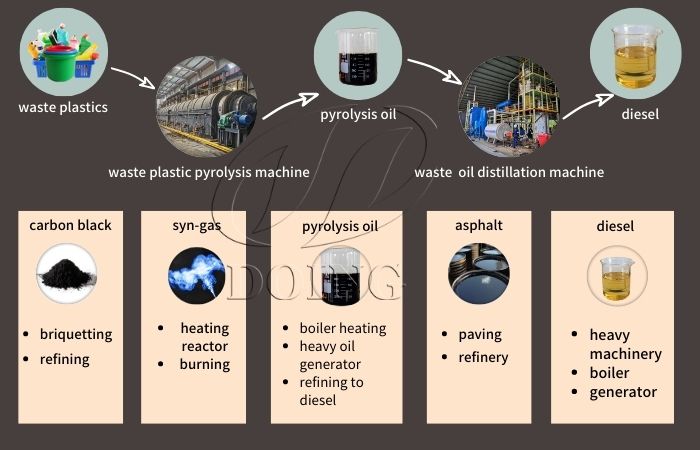

As shown in the video, pyrolysis is a highly effective waste management solution. By feeding organic wastes into pyrolysis equipment, these materials can be converted into valuable fuels and other usable products. This not only significantly reduces the volume of waste sent to landfills but also mitigates environmental pollution caused by non-biodegradable waste accumulation.

Waste to fuel pyrolysis technology

Waste to fuel pyrolysis technology

Energy production is one of the core applications of pyrolysis technology in the video. The combustible gases (e.g., methane, hydrogen, carbon monoxide) and liquid fuels (pyrolysis oil) generated during the pyrolysis process can be directly used as energy sources. For instance, pyrolysis oil can be refined into diesel via distillation machine, while the combustible gases can be recycled to fuel the pyrolysis furnace itself or used for power generation, providing a sustainable alternative to fossil fuels.

Waste to diesel pyrolysis technology application

Waste to diesel pyrolysis technology application

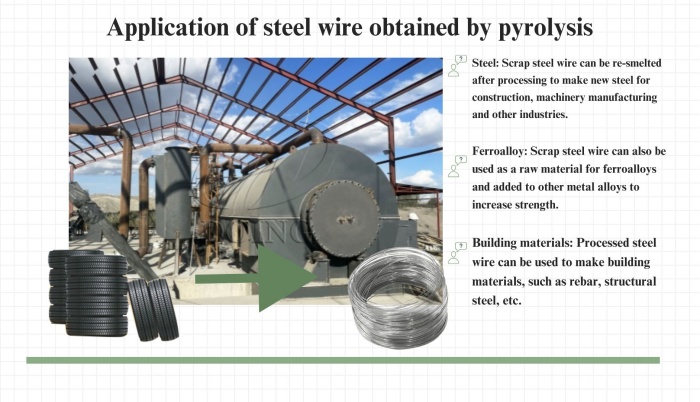

The video also explains how pyrolysis enables efficient material recycling. During the treatment of certain wastes, valuable materials like metals and carbon black can be recovered. The recovered metals can be reused in manufacturing, while carbon black— a key by-product— is widely used in rubber production, ink manufacturing, and as a fuel additive. This closed-loop recycling model further enhances the economic and environmental value of pyrolysis technology.

Waste tire steel wire pyrolysis technology application

Waste tire steel wire pyrolysis technology application

Pyrolysis technology is a versatile and crucial process. In the next video, we will introduce you to the working principle of pyrolysis technology.

Request Information

Send your inquiry for further information