Home > FAQ > Waste Oil Distillation Plant>What’s the working process of the waste oil distillation machine?

Home > FAQ > Waste Oil Distillation Plant>What’s the working process of the waste oil distillation machine?

What’s the working process of the waste oil distillation machine?

Waste Oil Distillation Plant / Date:June 28, 2021

The workflow of waste oil distillation machine includes high-temperature distillation, circulating water cooling, catalyst deodorization and clay decolorization, then can refine waste oil into diesel, the waste oil can include black and heavy oil, tire/plastic pyrolysis oil, waste engine oil, crude oil, etc. Next, I’ll take the Doing Group waste oil distillation machine as an example to introduce the workflow of the waste oil distillation machine.

Waste oil distillatioin machine

Waste oil distillatioin machine

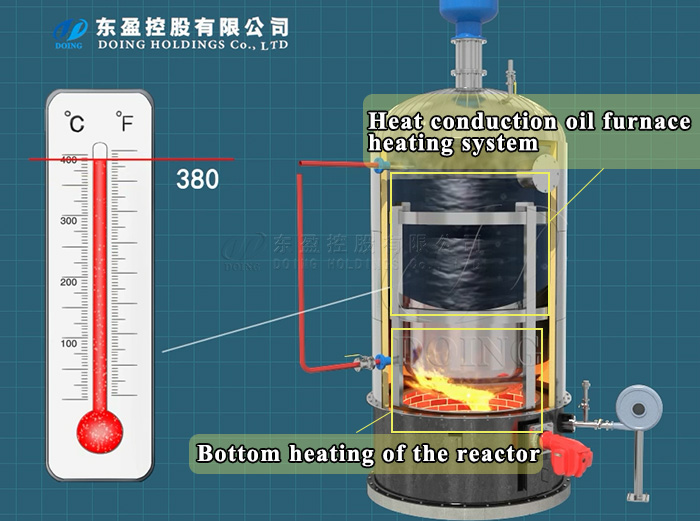

1. Heat conduction oil system preheating preparation

Open the exhaust valve of the system pipeline, start the oil injection pump, and send the heat conduction oil into the expansion tank. The heat conduction oil gradually fills the entire system through expansion by its own weight. Then start the circulating pump to make the heat conduction oil circulate in the system;

2. Circulating water cooling preparation

Turn on the cooling circulating water pump and open the corresponding valve to make the condensed water circulate normally in the horizontal condenser;

3. Heat conduction oil heating

When the temperature of the heat conduction oil reaches 250 degrees, keep it for about 1 hour so that the moisture and bad emulsifiable concentrate contained in the waste oil can be fully volatilized and then enter the first fraction tank; Continue to heat the heat condution oil to make the temperature of the distillation reactor reach 290 degrees, turn on the burner to heat, and control the temperature of the distillation reactor between 380 degrees and 400 degrees, and the oil gas will generate;

The double heating system

The double heating system

4. Oil gas condensation

The oil gas are cooled down into oil through the horizontal condenser and enter the second fraction tank. At the same time, the uncondensable but combustible oil gas passes through the second fraction tank and water seal, and is collected by the tail gas burner to heat the distillation reactor;

Then, continues to maintain the temperature of the distillation reactor between 380 degrees and 400 degrees and the oil gas enters the catalytic tower through the buffer tank for catalytic reaction, and then pass through the horizontal condenser to condense into oil and then enter the third fraction tank. The uncondensable gas is collected to heat distillation reactor.

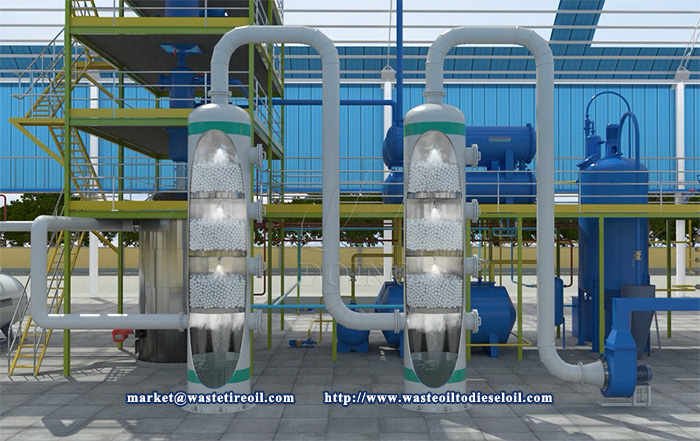

5. Decolorization and deodorization

Turn on the vacuum water pump, pour the oil in the third fraction tank into the deodorization tank, and deodorize with the catalyst; then pour the deodorized oil into the decolorization tank, pour the white clay to decolorize; then turn on the filter oil pump to filter the decolorized oil. Then the filtered oil can be injected into the product oil tank.

6. Smoke treatment

The smoke from the heat conduction oil furnace and the distillation reactor passes through the pipeline into the desulfurization tower for treatment, and the treated smoke can meet the national gas emission standards.

The desulfurization tower

The desulfurization tower

The above is the introduction to the workflow of waste oil distillation machine. In addition, Doing Group also provides 3D animation videos and project case videos for customers' reference. If you want to know more information about waste oil distillation machine, welcome to consult feel free.

Request Information

Send your inquiry for further information