How to refine waste oil into diesel?

Waste Oil Distillation Plant / Date:July 9, 2021

The rapid economic development has made the discharge of waste oil reach an unprecedented height. However, if the waste oil is not handled properly, there will be many unimaginable risks, such as soil pollution, water pollution and so on. So how can waste oil be better handled? One of the best ways to dispose of waste oil is to refine it into diesel by waste oil distillation machine, which not only can solve the pollution potential caused by waste oil, but also diesel oil has a wide range of uses.

Doing waste oil distillation machine is specially designed for refining waste oil to diesel. Through high-temperature distillation, cooling into oil, decolorization and deodorization, the waste oil is finally refined into clean diesel with clear color.

Waste oil distillation machine

Waste oil distillation machine

Now let’s take a look at how waste oil is refined into diesel.

1. Pretreatment of heat transfer oil and condensate water

Pre-preparation for the heat transfer oil cycle, start the oil injection pump, and send the oil to the expansion tank. The heat transfer oil gradually fills the entire system by its own weight through the expansion tube. Turn on the cooling circulating water pump to make the condensed water circulate normally in the horizontal condenser.

2. High temperature distillation

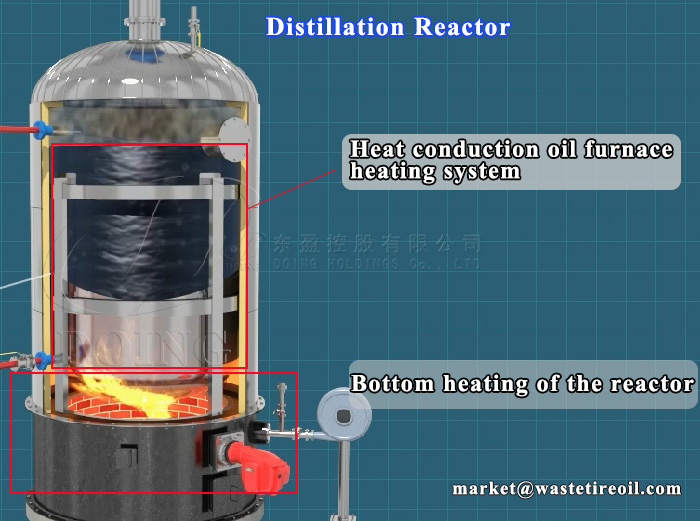

Feed the waste oil into the distillation reactor by the oil pump, the heat transfer oil and the burner are used to heat the reactor at the same time. In a high temperature and oxygen-free environment, the distillation reactor will produce oil and gas after reaching a certain temperature.

Double heating distillation reactor

Double heating distillation reactor

3. Cooling into oil

The heat-conducting oil heats the distillation reactor to 250 degrees Celsius, allowing the water and emulsified oil to fully evaporate. After buffering in the buffer tank, it enters the horizontal condenser, where it condenses into oil and is finally stored in the first fraction tank.

The heat-conducting oil and the burner are heated simultaneously to the distillation reactor to 380-400 degrees Celsius, there will be oil and gas volatilization, after buffering in the buffer tank, it enters the horizontal condenser and condenses into oil, which is stored in the second distillation tank.

The temperature of the reactor continues to be maintained at 380-400 degrees Celsius. The volatilized oil gas passes through the buffer tank and is catalyzed by the catalytic tower.Then it enters the horizontal condenser, and is condensed into oil to be stored in the third fraction tank.

4. Exhaust gas purification

The non-condensable oil and gas in the condensing system is purified by a water seal and used as fuel to heat the distillation reactor.

5. Decolorization and deodorization

Finally, feed the oil in the oil tank into the decolorizing pot, and the white clay is added to stir to decolorize. Then the oil fully mixed with the white clay is pumped into the leaf filter to obtain a clear color oil, which is followed by finely filtered to remove impurities. You can get clean, bright non-standard diesel.

6. Flue gas treatment

The flue gas produced by the heat-conducting oil furnace and the reactor is processed by the desulfurization tower and discharged into the atmosphere after meeting the national emission standards.

Desulfurization tower to purify flue gas

Desulfurization tower to purify flue gas

Recycling waste oil can not only make full use of resources, but also has significant economic benefits. This has become our consensus. Our Doing company has sufficient experience in this area, and our waste oil distillation machine has many unique advantages. If you want to know more details, please feel free to contact us.

Request Information

Send your inquiry for further information