Make oil from plastic ?

Waste Tire/Plastic Pyrolysis Plant / Date:February 6, 2018

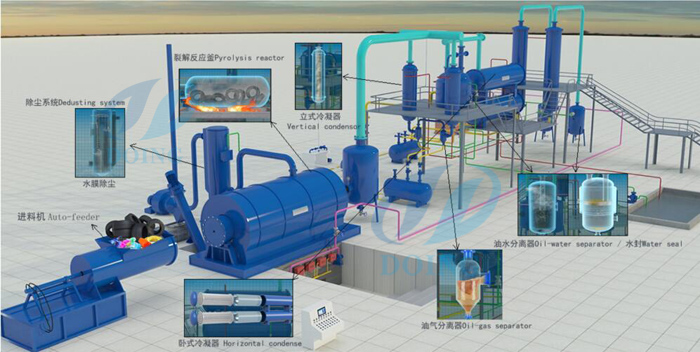

Making oil from plastic by waste plastic pyrolysis plant

Plastic waste recycling can provide an opportunity to collect and dispose of plastic waste in the most environm ental friendly way and it can be conve rted into a resource. In most of the situations, plastic waste recycling could also be economically viable, as it generates resources, which are in high demand. Plastic waste recycling also has a great potential for resource conservation and GHG emissions reduction, such as producing dies el fuel from plastic waste. This resource conservation goal is very important for most of the national and local governments, where rapid industrialization and economic development is putting a lot of pressure on natural resources. Some of the developed countries have al ready established commercial level resource recovery from waste plastics.Doing produced waste plastic pyrolysis plant not only can solve the plastic waste problems ,but also can bring much more profit for you.

Make oil from plastic working process

Waste plastic pyrolysis plant pyrolysis waste plastic to fuel oil and carbon black

1.Put raw material into reactor by full-automatic feeding machine. The reactor is supposed to be left 1/3 space for rotating more smoothly. Then make sure the door of feeding machine is closed.2.Reactor will be gently heated by burning the fuel material (coal, wood, natural gas, LPG or tire oil generated from last batch). The oil gas will be released when the temperature reached 100℃ (250-280℃ is the top output rate interval). Heavy oil gas separated by manifold is supposed to be liquefied and drop down into the heavy oil tank. The lighter gas will rise up to the oil condensers, be liquefied into oil and stored in the oil tank. The incondensable gas through dusulphuration and dedusting by hydroseal will be led to the furnace for recycling.

Waste plastic pyrolysis plant

4.There possibly will be a little exhaust gas left, and you should not expel it until it has reached the emission standard.

5.Before starting next batch, make sure all the work has been done.

Request Information

Send your inquiry for further information