Oil sludge treatment plant

In the process of oil development, storage, transportation, and use, due to uncontrollable factors in the operation process, crude oil may leak out and combine with soil and impurities to produce oil sludge. Oil sludge contains a large amount of oil, water, inorganic materials, radioactive elements, dioxins, pathogenic bacteria and other toxic and harmful substances that are difficult to degrade, causing serious damage to the environment and endangering human health. Therefore, it is very necessary and urgent to treat and utilize oil sludge technically and resourcefully. Oil sludge treatment plant can extract oil sludge into fuel oil, water, and soil, which is used at home and abroad. Our DOING oil sludge treatment plant is equiped with high quality environmental protection equipment, which can treat oil sludge in a harmless and environmentally friendly manner, and well received by costomers.

DOING oil sludge treatment plant

DOING oil sludge treatment plant

Oil sludge treatment plant working process

The process of oil sludge treatment plant

The process of oil sludge treatment plant

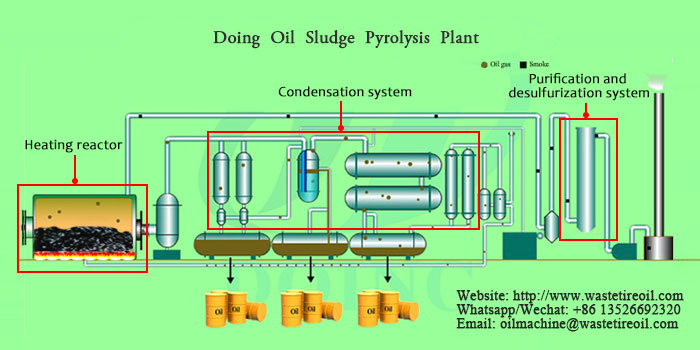

1.The oil sludge is loaded into the pyrolysis reactor of oil sludge treatment plant. After heating the reactor, the oil sludge will be vaporized into oil gas.

2.The oil gas will goes through condensation system, and the liquefiable part is condensed into fuel oil, the non-liquefiable part is sent to the furnace to heat the pyrolysis reactor, which saves fuel resources and does not pollute the environment.

3.The flue gas produced after combustion in the furnace goes through desulfurization and purification tower to remove soot and hydrogen sulfide, which finally meets environmental standards and can be discharged safely.

Oil sludge treatment plant advantages

1. The pyrolysis reactor body is rotated 360 degrees outside, which is evenly heated and makes the oil sludge treatment plant durable.

2. There is a reversing device in the reactor, so that the raw materials can be reversed more than 4000 times from feeding to discharging, and the oil sludge is highly dispersed in the reactor, with uniform heating and fast pyrolysis speed.

3. Oil sludge treatment plant is equipped with flue gas desulfurization and purification system, which can make the whole treatment process environmental standards, no secondary pollution.

4. Oil sludge treatment plant is also equipped with safety systems such as oil-water separator, water seal device, vacuum device, etc. to ensure that the whole pyrolysis process is safe and stable.

Oil sludge treatment plant final products

The oil sludge after pyrolysis by oil sludge treatment plant can be converted into fuel oil, water and soil. And they can be used in different fields for different purposes.

Final products of oil sludge treatment plant

Final products of oil sludge treatment plant

1. The fuel oil can be used as fuel in heavy oil burners, cement factory, glass factory, ceramic factory, electric power factory, steel making factory, and so on. And it can also be refined by waste oil distillation plant to get non-standard diesel which can be used in heavy trucks and other large mechanical equipment.

2. The water after treatment can meet environmental requirements and can be recycled or discharged directly.

3. The soil can be used to make bricks and other construction materials.

Henan Doing Environmental Protection Technology Co., Ltd specializes in research and development, manufacturing waste tires, waste plastics, oil sludge treatment plant and further refining pyrolysis oil to diesel distillation plant, we are sure that our products are durable and reliable quality, welcome to contact us.

Request Information

Send your inquiry for further information