Coal tar residue treatment pyrolysis plant for sale

The coal tar residue treatment pyrolysis plant for sale adopts a thermal pyrolysis process to heat the coal tar residue at high temperature under anaerobic or anoxic conditions to decompose the macromolecules in the organic matter into small molecules of flammable gas, liquid fuel and coke, thus obtain valuable products such as fuel oil, carbon black, and combustible gas.

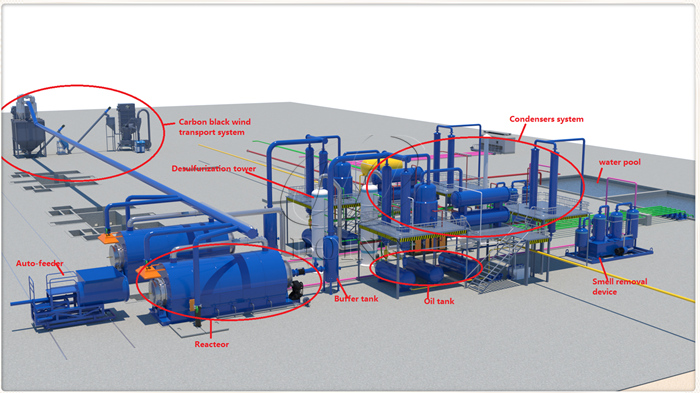

Coal tar residue treatment pyrolysis plant

Coal tar residue treatment pyrolysis plant

Coal Tar Residue Treatment Pyrolysis Plant Details

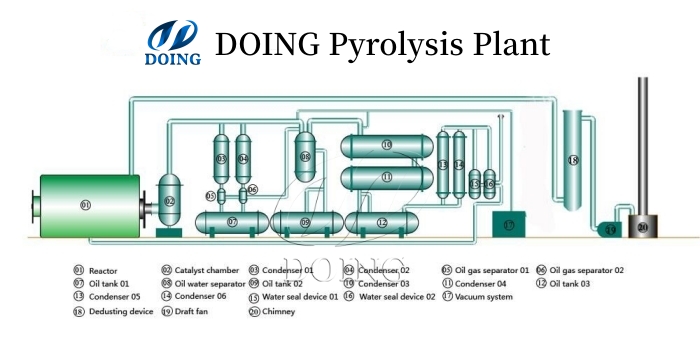

A complete coal tar residue treatment pyrolysis plant consists of a feeding system, a pyrolysis system, condensation system, heating system, slag discharge system, flue gas treatment system and PLC control system. The pyrolysis system is main and important part of the whole coal tar residue treatment pyrolysis production line.

Coal tar residue treatment pyrolysis plant machine details

Coal tar residue treatment pyrolysis plant machine details

The pyrolysis system of DOING coal tar residue treatment pyrolysis plant adopts a horizontal reactor structure, consisting of furnace bladder, insulation shell and the base. The material selection, equipment estimation and insulation design of the entire pyrolysis reactor system have gone through multiple tests and strict quality control to ensure safe and stable operation of the coal tar residue.

Coal Tar Residue Treatment Pyrolysis Plant Working Process

1. Feeding: Lift or dump the coal tar residue into the hopper, and then send the coal tar residue into the pyrolysis furnace through the spiral feeding system.

2. Pyrolysis: Start the burner for preheating. Preheating takes about 2 hours. When the temperature of the pyrolysis reactor furnace reaches 180°C, the coal tar residue begins to undergo pyrolysis reaction in the pyrolysis furnace.

Coal tar treatment pyrolysis plant euipment details

Coal tar treatment pyrolysis plant euipment details

3. Oil production: When coal tar residue undergoes pyrolysis reaction, oil gas begin to be produced. The oil gas first pass through a buffer tank to separate heavy oil residue and light oil gas; then, the light oil and gas are cooled into liquid fuel in the condensation system, that is, pyrolysis oil, and then flow into the oil storage tank.

The condensation system of DOING coal tar residue treatment pyrolysis plant for sale consists of vertical condenser, horizontal condenser and condensation tower, with a condensation area of up to 100 square meters, ensuring that the oil gas is fully cooled and increasing the oil yield.

4. Slag discharge: What remains in the pyrolysis reactor after the pyrolysis of coal tar residue is carbon black residue, etc. The carbon black residue is discharged through the automatic slag discharging system and stored in the carbon black tank.

5. Exhaust gas purification: Non-condensable combustible gases are purified through water seals and purification devices and then sent to the combustion chamber of the pyrolysis system as fuel for heating.

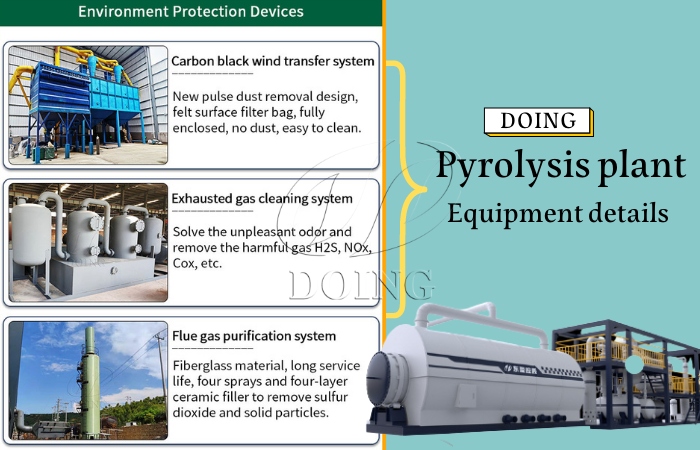

6. Flue gas desulfurization and dust removal: The flue gas generated is first treated by condensation and cooling in the flue, and then passes through multi-stage purification such as desulfurization tower, denitrification tower, dust removal, activated carbon adsorption, etc. before being discharged to the standard.

Technical Characteristics of Coal Tar Residue Treatment Pyrolysis Plant

Environmentally friendly: The coal tar residue treatment pyrolysis plant is equipped with gas purification system to ensure that waste emissions such as waste smoke and exhaust gas meet national standards and are clean and environmentally friendly;

Energy saving and consumption reduction: The collection and utilization of combustible gas can realize the heating of the pyrolysis system, eliminating the need for additional heat sources, saving energy, reducing emissions and consumption.

Prevent coking and sticking: The inner tank of the main furnace of DOING coal tar residue treatment pyrolysis plant for sale is made of stainless steel, which has better corrosion resistance. The inner wall is specially equipped with a decoking device to prevent wall sticking and coking.

Wide material adaptability: Strong adaptability and tolerance to raw materials. The technology is used in waste tires, was te plastics, waste oily sludge pit/mud, aluminum plastic, domestic waste, medical waste and other solid waste and hazardous waste treatment fields.

Intelligent automation: The coal tar residue treatment pyrolysis plant has a high degree of automation. Through the PLC intelligent control system, each individual equipment and process control point are monitored in real time, truly realizing intelligent and safe operation, with low staffing requirements.

Environmental devices of coal tar residue treatment pyrolysis plant

Environmental devices of coal tar residue treatment pyrolysis plant

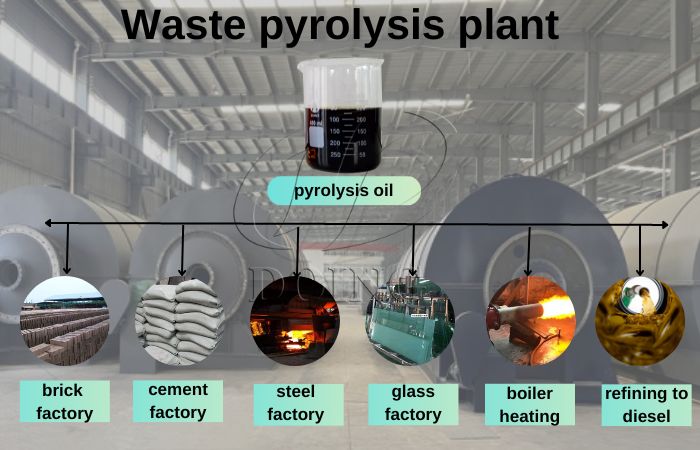

Coal Tar Residue Treatment Pyrolysis Plant Final Products

1.Fuel oil: Fuel oil refined from coal tar residue is beige, clear and translucent, and has high calorific value. It can be widely used in industrial heating fuel fields, such as power generation, steel/brick/cement/glass making factories, etc. Or you can adopt the pyrolysis oil distillation plant to refine it into diesel fuel.

Coal tar pyrolysis oil applications

Coal tar pyrolysis oil applications

2. Carbon black: equivalent to sub-coal or coal ball, has a certain calorific value and is used for industrial heating.

3.Combustible gas: recycle for heating the pyrolysis reactor.

Henan Doing Company has been committed to the research, development and update of pyrolysis technology for years. The quality of the coal tar residue treatment pyrolysis plant for sale is stable and reliable, and the equipment has passed multiple qualification certifications. DOING brand enterprise is trustworthy!

Prev:Nothing

Request Information

Send your inquiry for further information